|

|||

|

|

|||

|

Page Title:

Section IV. OPERATOR'S MAINTENANCE |

|

||

| ||||||||||

|

|

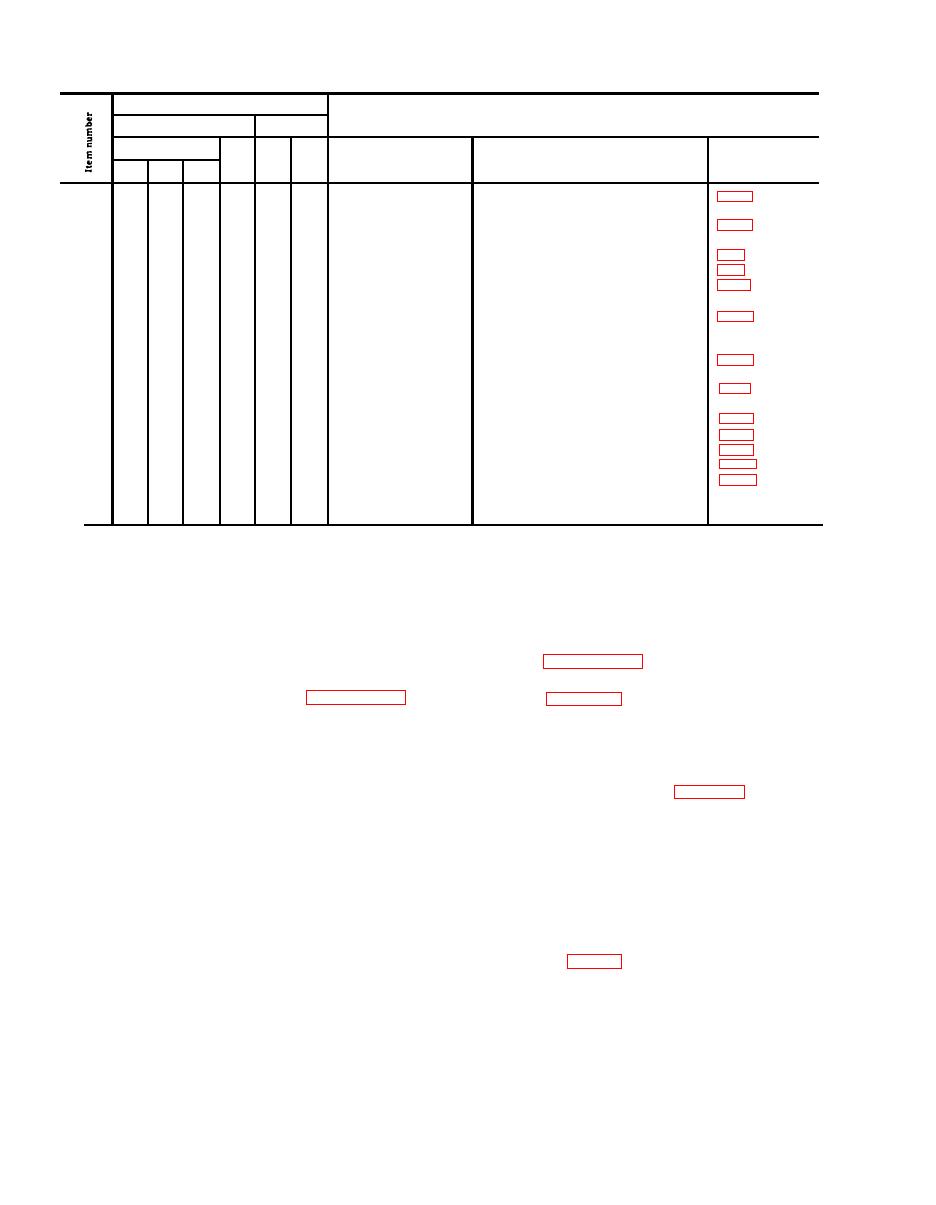

Table 3-1. Preventive Maintenance Checks and Services - Continued

Interval

B - Before operation

A - After operation

M - Monthly

D - During operation

W - Weekly

Q - Quarterly

Org.

Operator

Daily

W

M

Q

Item to be inspected

Procedure

Reference

A

D

B

Inspect for leaks, clean fill plug vent,

Brake master cylinder

X

20

add fluid as required.

Adjust if brake pedal does not have

Brake pedal

X

21

inch free travel.

Check operation. Inspect for leaks.

Steering gear

X

22

Check for proper pedal operation.

Inching pedal and valve

X

23

Remove and clean vent valve with an

Crankcase vent valve

X

24

approved cleaning solvent.

(PCV)

Inspect for insecure mounting and leaks.

Fuel pump

X

25

Clean bowl and screen. Replace bowl

gasket.

Correct deficiencies if brake application

Brakes

X

26

is spongy, or ineffective.

Check engine compression, vacuum and

Engine tune up and

X

27

timing.

test

Check and adjust electrical components

Electrical system

X

28

including alternator, voltage regulator

and starter.

Check brake lining. If lining is worn to

Service brake lining

X

29

less than 1/16 inch thickness, replace

brake shoes.

Section IV. OPERATOR'S MAINTENANCE

3-10. Air Cleaner Service

3-8. General

This section contains information on maintenance of

a. Refer to paragraph 3-9 and remove the seat from

truck.

the fork lift truck which is the responsibility of the

operator and which is not covered in paragraph 3-7.

b. Refer to figure 3-2 to service or remove the air

cleaner.

3-9. Operator's Seat Removal

Caution: Do not remove the air cleaner when

the engine is running. Do not run the engine unless

a. The operator's seat is mounted over the engine

the air cleaner is in place.

compartment forward of the counterweight. For ease

c. Remove the cup as shown in figure 3-2 and serv-

of access to the engine compartment and its com-

ponents the seat is readily removable.

ice as follows:

b. To remove the seat, lift rear of seat to clear pins

(1) Pour out the old oil from the cup. Scrape away

accumulated dirt from bottom of cup.

and slide the seat forward to clear rear seat mount

(2) Clean the cover, oil cup, and base assembly

flange.

c. Tilt seat forward and lift seat and mount from

inside and out with cleaning compound, solvent

truck by sliding forward flange of mount from frame.

(Spec. P-S-661) and dry thoroughly.

d. To install seat, lift into position and slide front

(3) Refill oil cup (1 pint capacity) with engine

flange under frame. Lower seat into position and

oil (OE) of grade and weight presently used in engine.

slide seat to rear to engage rear flange and pins.

d. Install cup (fig. 3-2).

3-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |