|

|||

|

|

|||

|

Page Title:

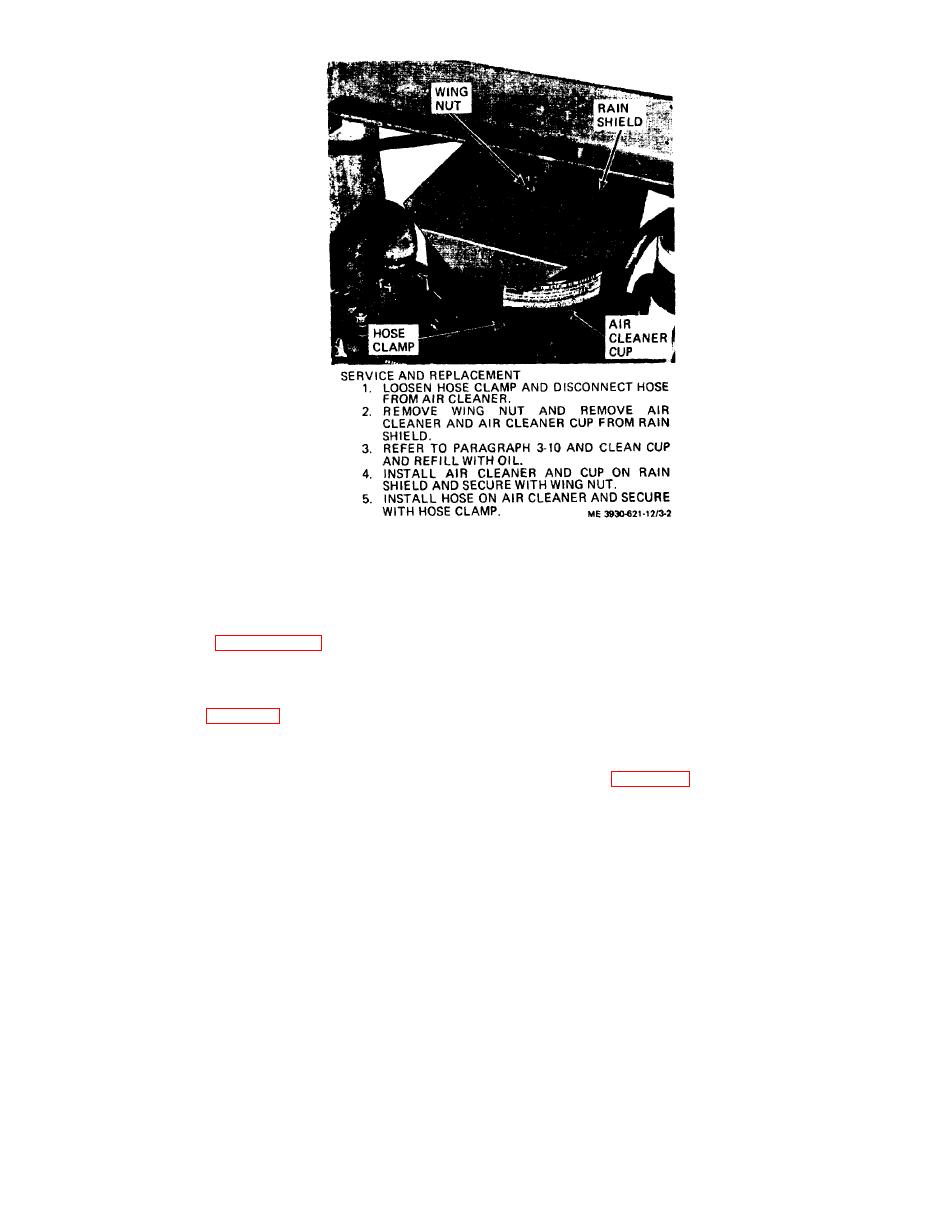

Figure 3-2. Engine air cleaner, service and replacement |

|

||

| ||||||||||

|

|

Figure 3-2. Engine air cleaner, service and replacement

filler caps are tight to prevent any of the solution

3-11. Battery and Cable Service

from entering the cells.

e. When foaming stops, flush battery and cable

truck.

terminals with clean, fresh water.

b. Remove caps to check level of fluid in battery.

f. Replace damaged or frayed cables.

Fill to 3/8-inch above plates if necessary.

g. Check condition of battery using a hydrometer.

If specific gravity reading is 1.225 or lower, recharge

battery. A fully charged battery should read 1.265 to

Caution: Always disconnect battery ground

1.290 specific gravity.

cable (negative side) first.

d. Clean top of battery, posts, and cable terminals

Connect ground cable (negative) last.

with a solution of baking soda and water. Make sure

3-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |