|

|||

|

|

|||

|

Page Title:

Table 2-1. Troubleshooting - continued |

|

||

| ||||||||||

|

|

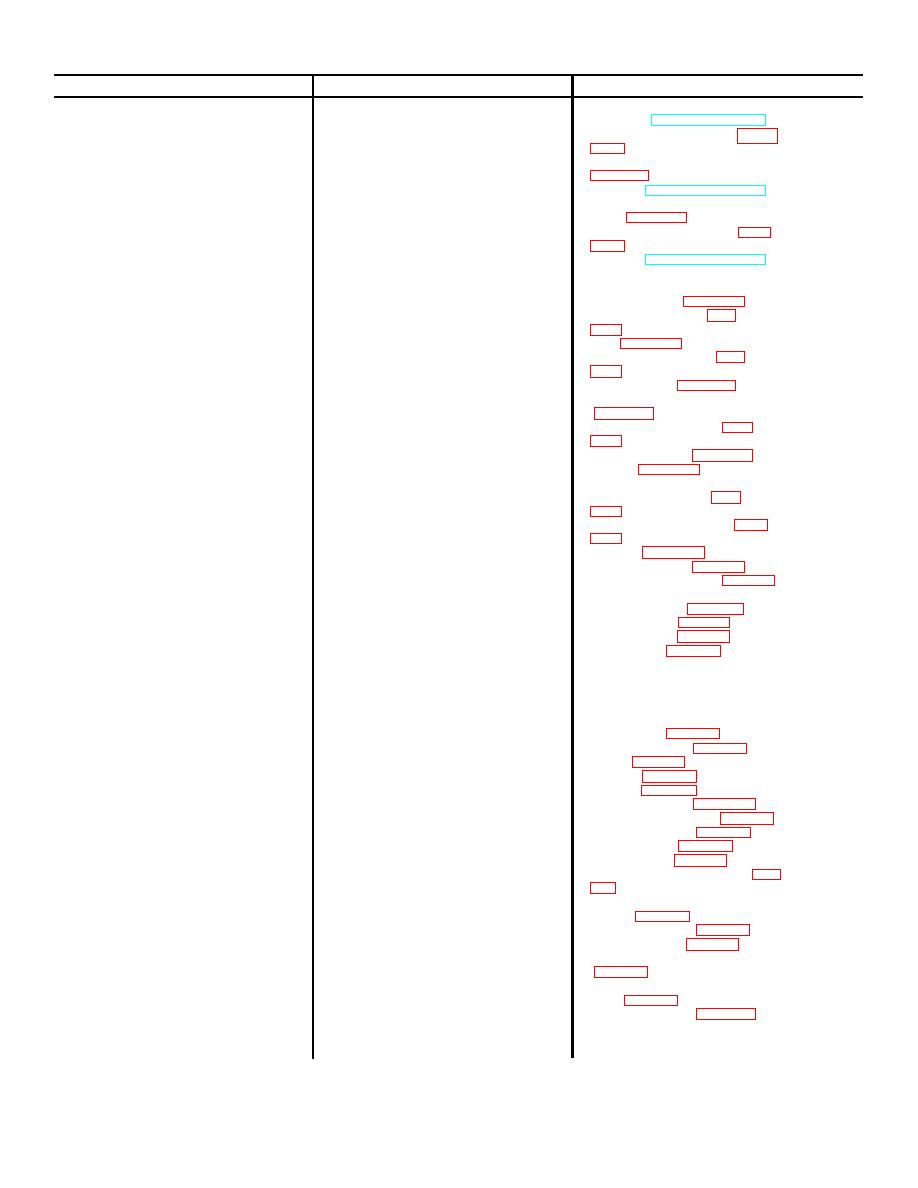

Table 2-1. Troubleshooting (Continued)

Malfunction

Probable cause

Corrective action

brake fluid TM 10-3930-618-20.

b. Clean out breather port (para

b. Breather port in master cylinder

clogged.

a. Replace broken or weak springs

27. One wheel drags.

a. Weak or broken brakeshoe return

springs.

b. Loose wheel bearings.

b. Readjust (TM 10-3930-618-20).

c. Replace defective or damaged

c. Swollen wheel cylinder piston cups

or piston binding.

parts (para .5-15).

a. Replace with new lining (para

28. Truck pulls to one side.

a. Grease or brake fluid on brake

lining.

b. Loose wheel bearings.

b. Readjust (TM 10-3930-618-20).

c. Make sure same type ,of lining is

c. Different brakes of brake lining.

used at each wheel.

d. Lining charred or drum scored.

d. Replace lining (para 5-13) or

repair or place drum (para

29. Spongy brakes.

Shoe surface not square with drum.

Repair (para 5-13).

a. Incorrect brake lining.

a. Install specified lining (para

30. Excessive pedal pressure

b. Oil or fluid soaked lining.

b. Replace lining (para 5-13).

a. Small amount of grease or brake

a. Correct cause and replace lining

31. Light pedal pressure-brakes too

severe.

fluid on lining.

b. Incorrect lining.

b. Install specified lining (para

c. Defective power booster.

c. Replace or repair (para 5-13).

a. Brake shoes twisted.

a. Replace(para 5-13).

32. Brakes squeak.

b. Particles of metal or dust im-

b. Remove foreign material, and

bedded in lining.

sand lining and drum (para

a. Cracked engine block or head.

a. Replace damaged part (para

33. Loss of coolant.

b. Defective head gasket.

b. Replace (para 3-20).

c. Leaky radiator.

c. Repair or replace (para 3-6).

34. Rapid wear or breakage of fan

Excessive drag from alternator.

Check alternator bearings (para 3-2).

belt.

a. Worn alternator brushes.

a. Replace brushes (para 3-2).

35. Ammeter does not show charge.

b. Shorted alternator armature.

b. Test alternator (para 3-2).

c. Shorted alternator fields.

c. Test alternator (para 3-2).

36. Ammeter shows discharge during

Inoperative alternator.

Test alternator (para 3-2)

engine operation.

determine cause.

37. Ammeter show heavy discharge

Defective alternator regulator.

Inspect for closed contacts. Adjust or

with engine stopped.

replace regulator (TM 10-3930-

618-20).

a. Dirty, loose or worn alternator

a. Clean and tighten brushes.

38. Ammeter shows rapid fluc-

tuation.

brushes.

Replace if worn (para 3-2).

b. Defective alternator.

b. Repair or replace (para 3-2).

a. Commutator dirty.

a. Clean (para 3-3).

39. Starting motor failure.

b. Worn brushes.

b. Replace (para 3-3).

c. Broken drive mechanism.

c. Replace (para 3-3).

d. Bad teeth on flywheel.

d. Replace ring gear {para 3-26).

a. Failure of hydraulic pump.

a. Replace or recondition (para 4-2).

40. Hard steering.

b. Badly worn pump.

b. Recondition pump (para 4-2).

c. Broken or weak relief valve spring.

c. Replace spring (para 4-2).

d. Binding relief valve.

d. Free up valve (para 4-2).

e. Low pump pressure.

e. Replace worn or faulty parts (para

f. Line leakage.

f. Tighten connections.

g. Leakage in steering cylinder.

g. Repair (para 5-7).

h. Faulty regulator valve.

h. Recondition valve (para 4-2).

i. Binding steering gear.

i. Repair (or adjust (para 5-7).

a. Pump pressure too high.

a. Check for binding relief valve

41. Steering too sensitive.

b. Faulty flow control valve.

b. Recondition-free tip any binding

parts (para 4-2).

42. Loose steering.

Loose kingpins.

Repair or recondition (para 5-10).

2-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |