|

|||

|

|

|||

|

Page Title:

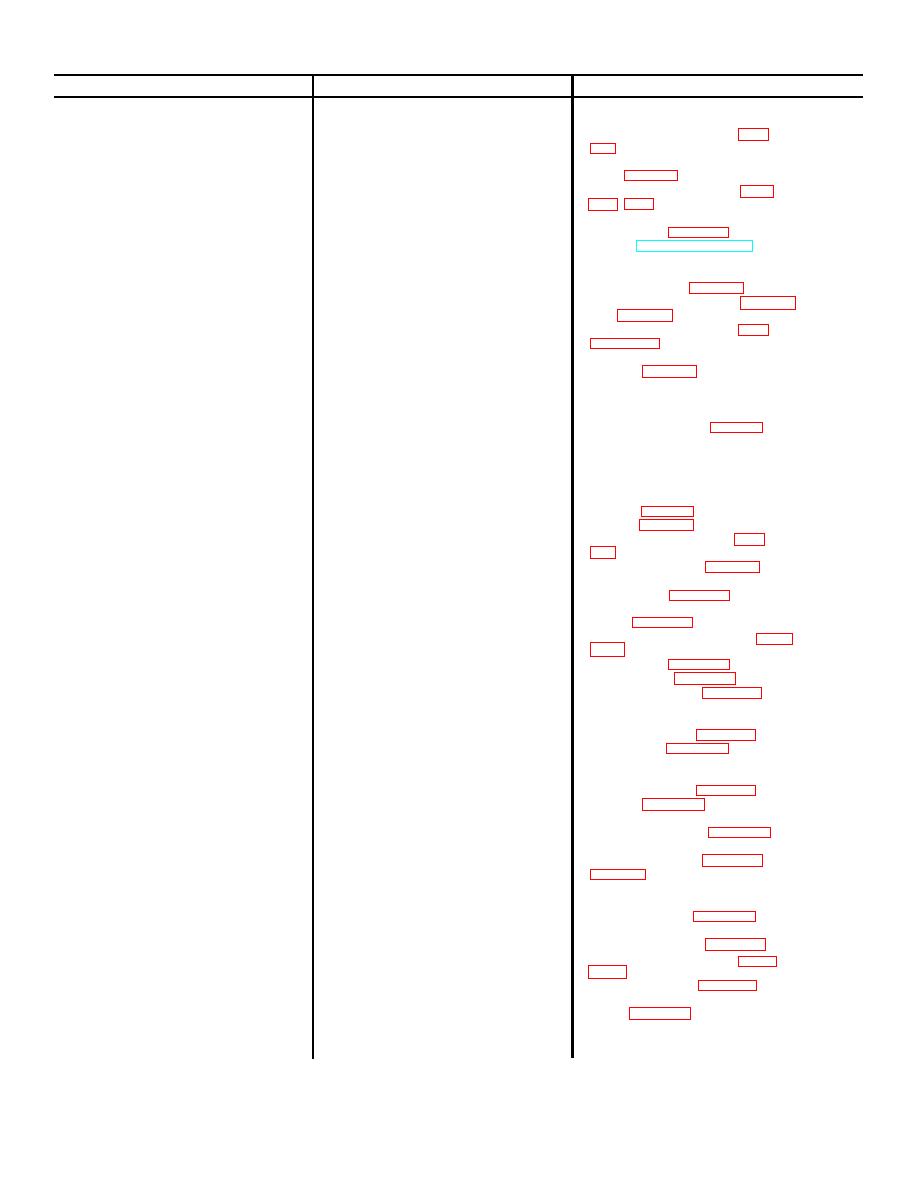

Table 2-1. Troubleshooting - continued |

|

||

| ||||||||||

|

|

Table 2-1. Troubleshooting (Continued)

Malfunction

Probable cause

Corrective action

e. Control valve inoperative.

e. Inspect for internal leakage or

damaged parts, and repair (para

a. Internal leakage at pump.

a. Inspect for worn or damaged

16. Lift and till too slow.

parts (para 4-2).

b. Excessive leakage at cylinder

b. Repair or replace packing (para

packing.

c. Air leaks in system.

c. Tighten all connections.

d. Misalignment.

d. Check mast (para 4-8) or tilt

linkage (TM 10-3930-618-20)

for cause of binding.

e. Faulty relief valve.

e. Check for worn or damaged parts.

Repair or replace (para 4-3).

a. Internal leakage in cylinders.

a. Repair or replace packing (para 4-5)

17. Load creeps when tilting or

lowering.

and para 4-6).

b. Oil leak at packing glands.

b. Repair or replace packing (para

c. Leak in control valve.

c. Check for worn or damaged

plungers (para 4-3).

d. Leaks in oil lines.

d. Tighten all connections or replace

damaged lines.

a. Check tank for proper oil level or

18. Noisy hydraulic pump.

a. Insufficient or no oil.

restricted suction line (para 4-4).

b. Air leaks.

b. Tighten intake connections.

c. Oil bubbles in intake oil.

c. Use hydraulic oil with antifoaming

characteristics. (LO 10-3930-

618-12).

d. Coupling misalignment

d. Realign.

e. Pump mounting flange I loose

e. Tighten (para 4-2).

f. Worn or broken parts.

f. Replace (para 4-2).

a. Internal oil leakage.

a. Repair or replace pump (para

19. Oil overheating.

b.

b. Remove and repair (para 4-2).

Pump too tight after overhaul.

c.

c. Check and repair.

Restricted lines.

a.

a. Replace axle (para 5-19).

20. Failure to operate.

Broken axle shaft.

b.

b. Replace axle shaft or planetary

Teeth broken on axle shaft

planetary gears.

gears. (para 5-19).

c.

c. Replace ring gear and pinion (para

Broken teeth on ring gear or

pinion.

d.

d. Replace disc (para 3-16).

Worn disc in transmission

e.

Worn transmission oil

e. Replace pump (para 3-15).

f.

f. Replace worn parts (para 3-16).

in transmission.

g.

g. Disassemble valve clean, and

Valve plunger stuck in transmis-

sion control valve.

replace worn parts (para 3-16).

a.

a. Replace disc (para 3-16).

21. Truck moves in one direction but

Worn disc in transmission.

not in other.

b. Binding valve plunger in trans-

b. Disassemble valve clean, and

mission control valve.

replace worn parts (para 3-16).

a. Excessive wear at ring gear and

a. Replace (para 5-20).

22. Axle noise drive or coast.

pinion.

b. Worn pinion gears or side gears in

b. Replace worn gears (para 5-21).

differential case.

a. Excessive wear in gear train.

a. Replace worn part (para 5-19

23. Continuous axle noise.

b. Lack of lubrication.

b. Lubricate according to LO 10-

3930-618-12.

c. Worn or damaged drive wheel

c. Replace bearings (para 5-20).

bearing.

a. Worn splines on axle shafts.

24. Excessive backlash in unit.

a. Replace axle shafts (para 5-19).

b. Worn ring gear, pinion or dif-

b. Replace gear and pinions (para

ferential case pinions.

c. Loose or worn universal joints.

c. Tighten or replace (para 5-21).

25. Pedal goes to toe board.

External leak in brake system or leak

Check master cylinder for leak and

past master cylinder piston cup.

repair (par 5-14).

a. Mineral oil in brake system.

a. Clean out system, replace cups in

26. Both brakes drag.

brake cylinders and refill with

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |