|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

c. Disassembly.

5-15. Wheel Cylinders

(1) Remove nipple (2, fig. 5-17), bleeder

a. Description.

The hydraulic wheel cylinder

screw (1), and elbow (13).

houses two opposed pistons which actuate two opposed

(2) Clamp top end of booster in padded vise.

brakeshoes. Pistons, rubber cups, and springs are held

(3) Carefully unscrew lower part of housing

in the cylinder by pressure from the brakeshoes. Open

from upper part, using a pipe wrench.

ends of the cylinder are protected by rubber boots.

(4) Grasp end of poppet (9) and carefully

b. Removal.

withdraw poppet, sleeve (8), spring (4), and lower cup

(1) Remove brake assemblies (para 5-13).

washer (11) from lower part of housing.

(2) Disconnect brake line at cylinder fitting.

(5) Remove spacer (6), cup washers (7 and

(3) Remove capscrew (8, fig. 5-13) and lock-

11), piston (10), and spring (12) from upper part of

washers (9) and remove cylinder from backing plate (18).

housing.

c. Disassembly.

d. Inspection and Repair.

(1) Remove rubber boots (12) from cylinder

(1) Inspect springs (4) and (2) for distortion or

ends.

stretching.

(2) Push out internal parts.

(2) Check poppet (9), sleeve (8), and piston

d. Cleaning and Inspection.

Use the same

(10) for scratches, burs, and improper sliding fit.

procedures for cleaning and inspection as those used for

(3) Inspect piston bore in upper housing for

the master cylinder (para 5-14). Replace defective parts

scratches or out-of-round condition.

as authorized.

(4) Remove and discard packing (5).

e. Assembly and Installation.

e. Assembly. Reverse procedures in c above.

(1) Reverse procedures in b and c above.

Make sure springs seat properly and no damage occurs

(2) Refer to TM 10-3930-618-20 for bleeding

to housing. Replace packing (5).

of brake system.

f. Installation.

5-16. Brake Pedal

(1) Reverse procedures in b above.

Refer to paragraph 3-17.

(2) Use a suitable thread compound on thread

5-17. Power Booster

connections and make sure connections are tight.

a. Description. The power booster is connected to

(3) Bleed the brake system (TM 10-3930-618-

the master cylinder outlet through a pipe nipple and is

20).

operated by pressure developed by the master cylinder.

The power booster multiplies this pressure and applies

the increased pressure to the wheel cylinders, resulting

in more positive braking.

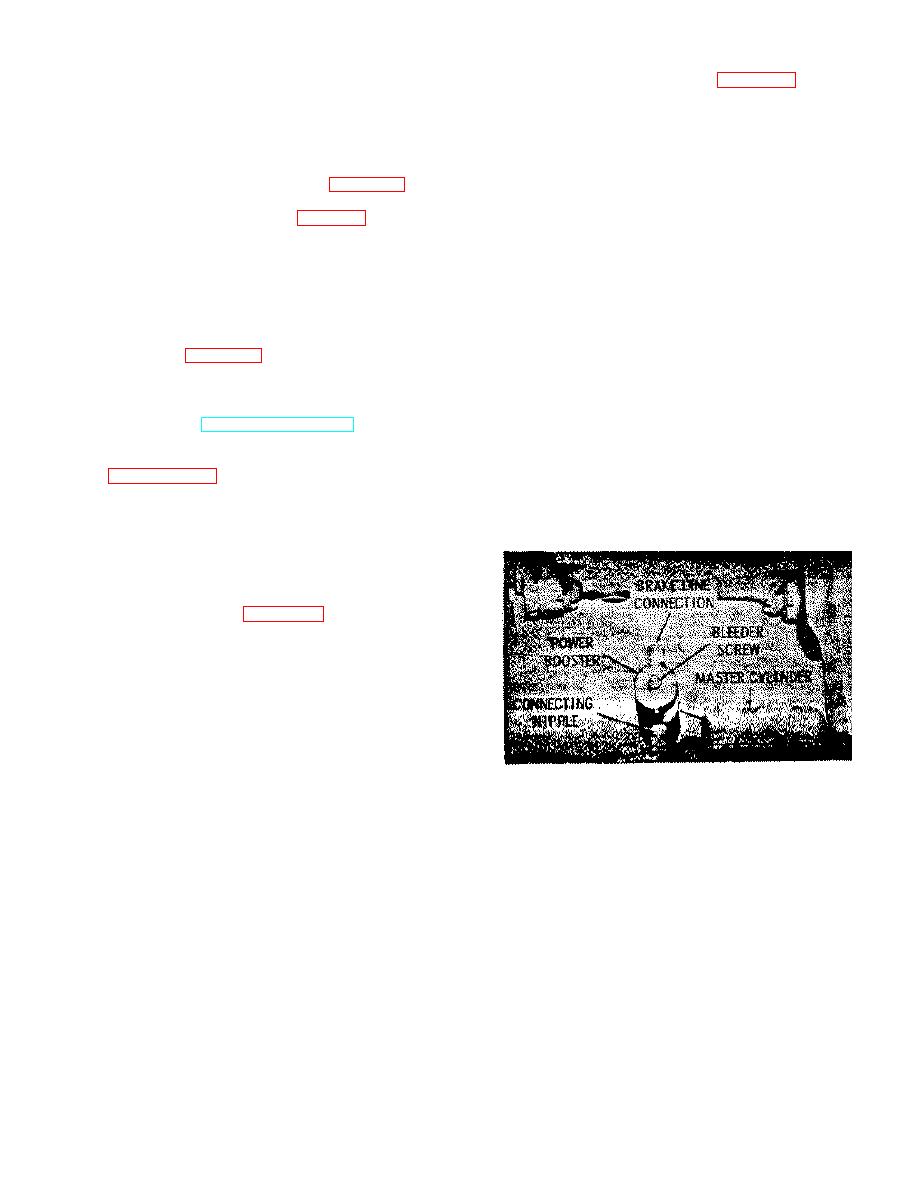

b. Removal. Refer to figure 5-16 and remove the

power booster as follows:

(1) Remove the floor plate.

(2) Disconnect the brake line at the power

booster.

(3) Using an open-end wrench of the proper

size, turn the connecting nipple clockwise, into the

master cylinder, while holding the power booster. The

nipple will turn out of the power booster.

Figure 5-16. Brake power booster, installed valve.

5-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |