|

|||

|

|

|||

|

Page Title:

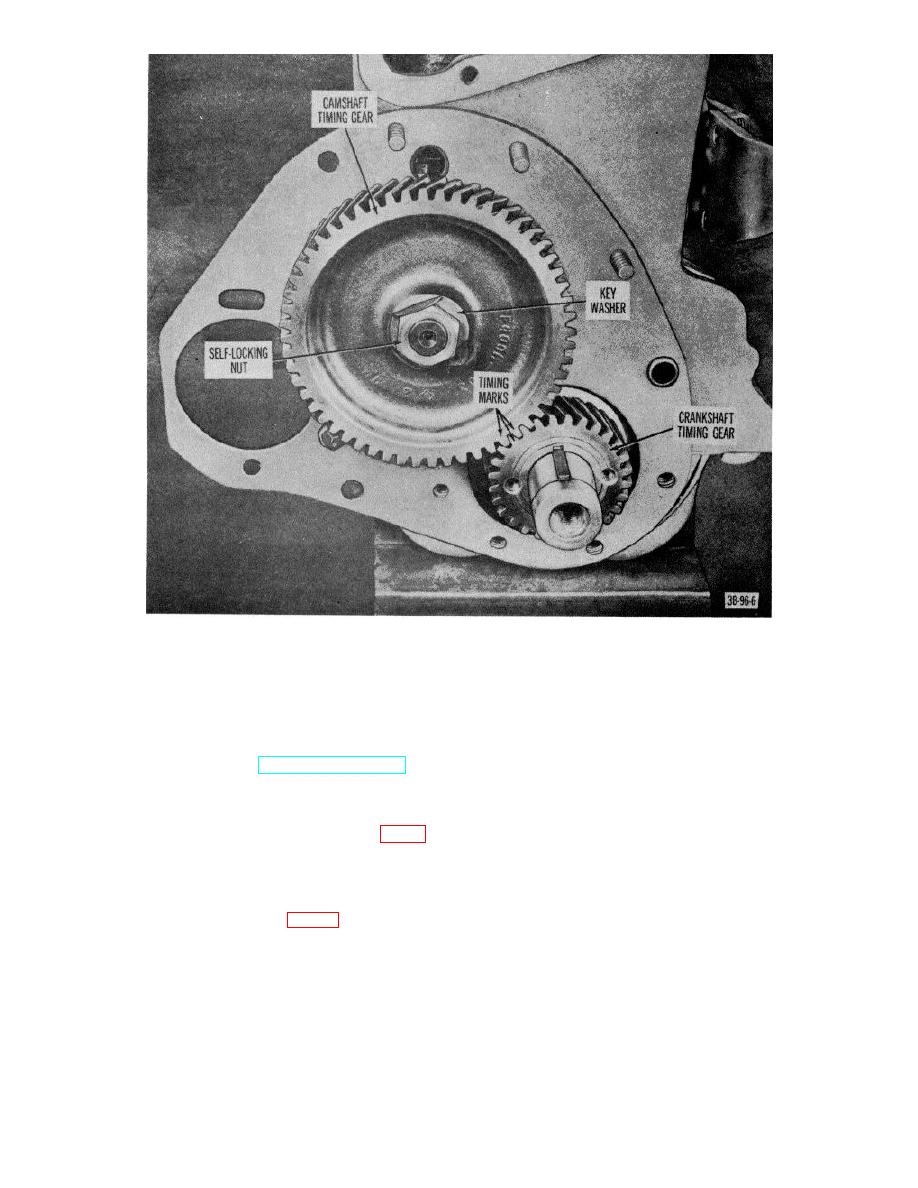

Figure 6. Crankshaft and camshaft timing gears, showing correct alinement of timing marks. |

|

||

| ||||||||||

|

|

Figure 6. Crankshaft and camshaft timing gears, showing correct alinement of timing marks.

(8)

Tag each valve so it may be installed

22. Valves

in opening from which it was

removed.

a. Removal

b. Cleaning and Inspection.

(1) Remove cylinder head (TM 10-3930-

(1) Clean valves with SD. Use a wire

222-20).

wheel to remove carbon from valve

face, seat face, and from under head

and gaskets (TM 10-3930-222-20).

of valve.

(3) Remove valve cover-to-cylinder block

(2) After valves are thoroughly cleaned,

studs, sleeve nuts, and valve

inspect them for evidence of burns,

chamber cover and gasket.

correct margin, pit, grooves, crack

(4) Using valve spring compressor (fig. 8),

stem wear, lock or groove wear, and

and with valve in closed position,

warping.

compress spring and remove the

(3) If it is necessary to grind exhaust valve

valve spring locks.

faces, set chuck or refacing machine

(5) Remove spring compressor.

for 45 seat angle. For intake valve

(6) Remove valve (1, fig. 9), valve spring

set chuck for 30seat angle.

(7), valve spring seat (8), and cap (9).

(7) Repeat procedure in (4) through (6)

above for the other valves.

AGO 7010A

12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |