|

|||

|

|

|||

|

Page Title:

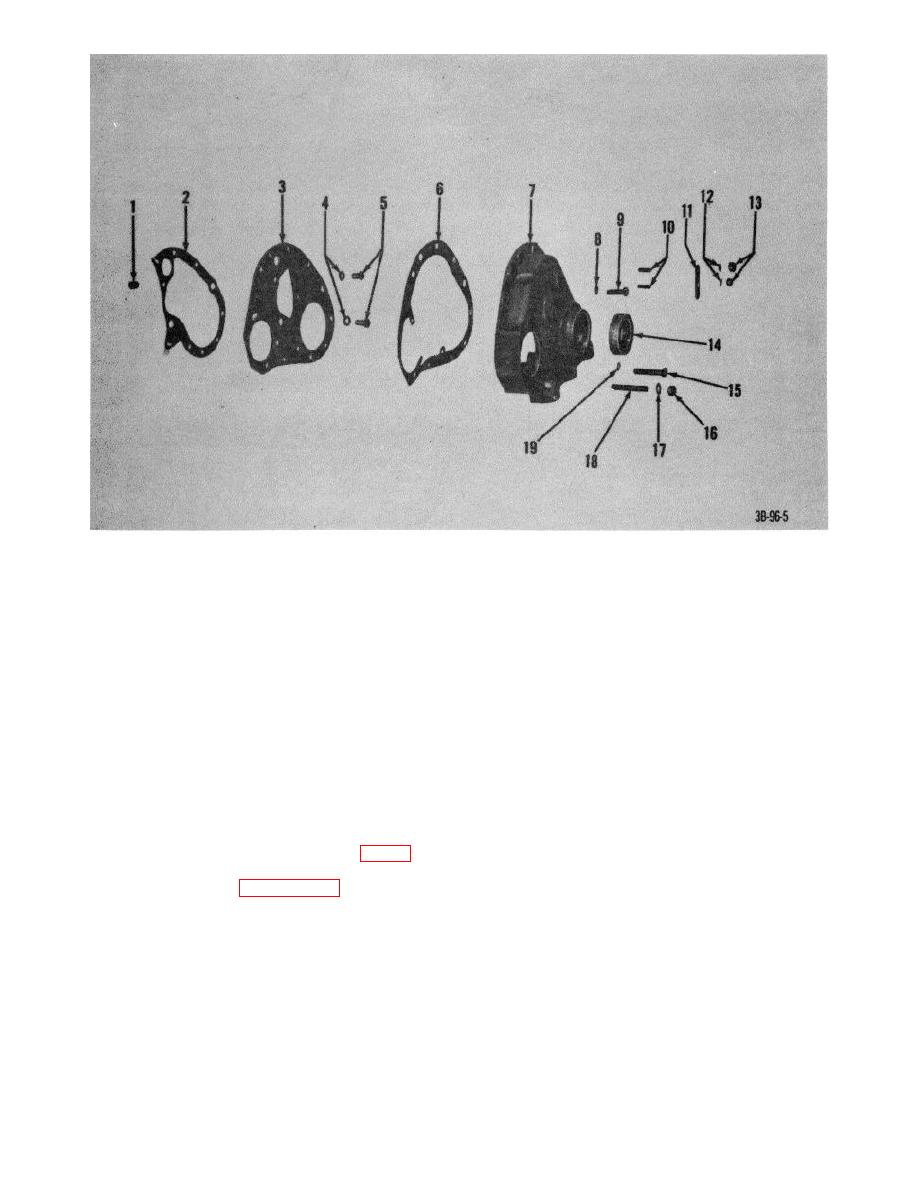

Figure 5. Timing gear over. exploded view. |

|

||

| ||||||||||

|

|

1

Dowel, ring, front end plate

11 Plate, marker

2

Gasket, front end plate

12 Lockwashers

3

Plate, front end

13 Nuts

4

14 Seal, plain, incased, cover

6

Capscrews

15 Capscrew

6

Gasket, cover

16 Nut

7

Cover, timing gear

17 lockwasher

8

lockwasher

18 Stud

9

Capscrew

19 Washer, flat

10

Stud, plain

Figure 5. Timing gear over. exploded view.

(2) Use an outside micrometer to measure

(1)

If sleeve bushings were removed for

the diameter of each camshaft

replacement, press bearings into

journal. If journal wear exceeds 0.002

position with a suitable bearing press.

inch, install new camshaft.

(2) Oil the camshaft journals and sleeve

(3) Use an inside micrometer or telescope

bearings and ease camshaft into

gage, and measure camshaft sleeve

position in cylinder block. The rear

bearings (8, 9, 10, and 11, fig. 7). If

end of the camshaft must be

clearance is not to specifications

supported and guided to prevent

listed in paragraph 7, install new

damage.

sleeve bearings at all journals. Be

(3) Untie the valve lifters and return them

certain that oil passages are alined

back into position.

and open.

(4) Reverse procedures (1) through (6) in a

(4) Inspect thrust plate and cams for wear;

above.

inspect journals and cams for scoring.

c. Installation.

AGO 7010A

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |