|

|||

|

|

|||

|

Page Title:

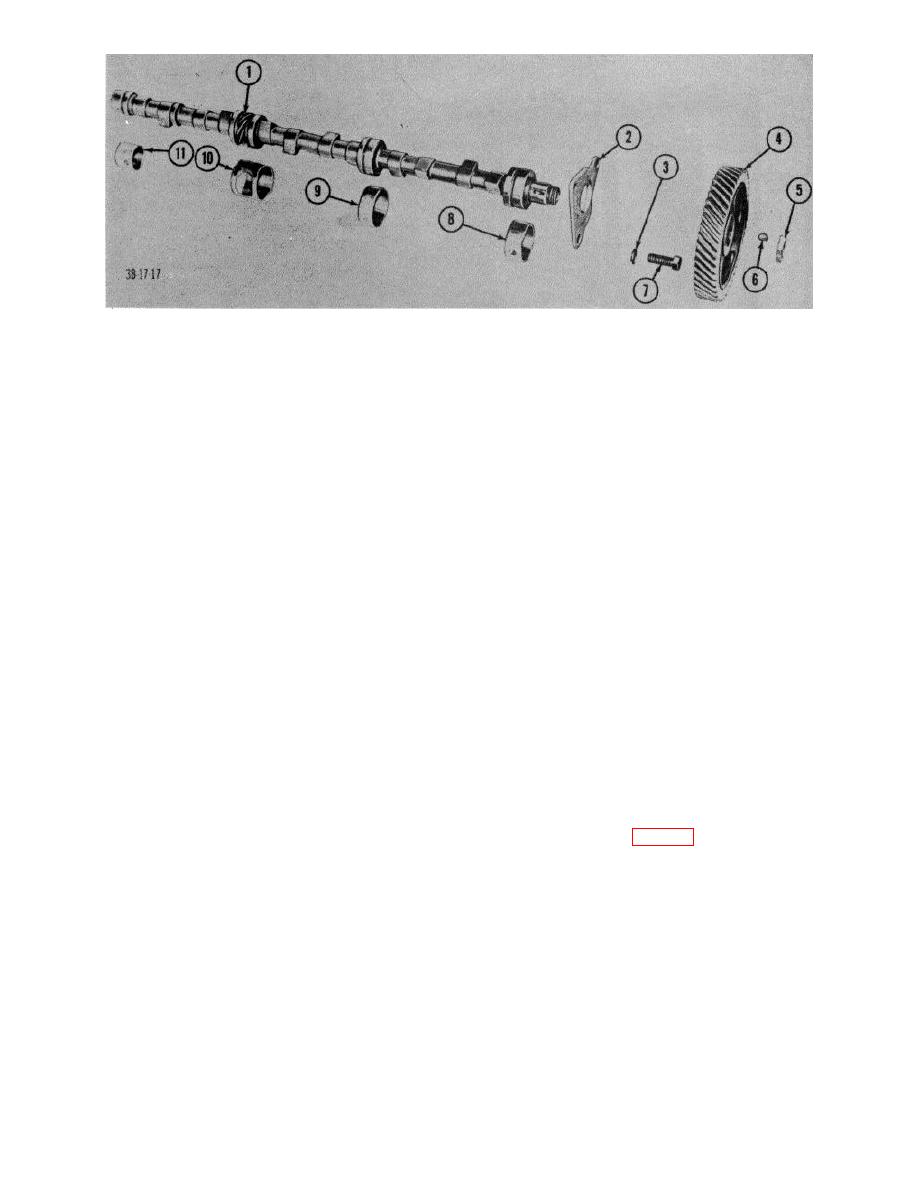

Figure 7. Camshaft, exploded view. |

|

||

| ||||||||||

|

|

1

Camshaft

7 Bolt, thrust plate

2

Plate thrust

8 Bearing, sleeve, front

3

Lockwasher, thrust plate bolt

9 Bearing, sleeve, intermediate front

4

Gear, timing

10 Bearing, sleeve, intermediate rear

5

Nut, self-locking, gear-to-camshaft

11 Bearing, sleeve, rear

6

Key, woodruff

Figure 7. Camshaft, exploded view.

valves, using above procedure.

Grasp valve on unworn portion of stem, close to head,

If any margin is below

and grind valve as follows:

minimum, discard valve and

(a) Position chuck so that contact is

install a new one.

just barely made between

c. Installation. Reverse procedure in a above.

grinding wheel and valve face

d. Adjustment. Refer to TM 10-3980-20.

Feeding. wheel slowly into

valve, make a very light cut

around entire valve face,

23. Valve Guides

always keeping valve in contact

a. Inspection and Cleaning.

with grinding wheel. If the cut

(1) Remove valve ((1) through (6), par. 22).

removes metal from one-half of

(2) Inspect guide for wear and carbon

valve face or less, inspect

deposits.

If carbon is excessive,

chucking (gripping) of valve. If

clean out with brush and/or proper

inspection reveals valve is

size reamer.

If guide is worn

squarely mounted, valve is

excessively so that valve stem

misalign

and

must

be

clearance

does

not

meet

discarded. If mounting is faulty,

specifications (par. 7), replace guide

check valve squarely and

(b and c below).

repeat operation. When face is

b. Removal.

ground

evenly

on

(1) With valve removed (a above), remove

circumference,

the

valve

valve lifter adjusting screw.

alinement is satisfactory.

(2) Using a suitable drift, knock valve guide

(b)

After first cut has proved

(5, fig. 9) down until lower end

satisfactory,

proceed

with

approaches valve lifter, and remove

grinding operation. Do not take

guide.

heavy cuts or remove more

(3) Repeat procedures in (1) and (2) above

metal than necessary to remove

for the remaining guides

all imperfections.

c. Installation. Mark point on driving mandrel 1

(c)

When valve face has been

15/32 inches from driving end, position new valve guide,

ground, remove valve and

and drive in until top of guide is 1 15/32 inches from top

check margin for minimum

of cylinder block.

thickness of 3/64 inch at any

point. If margin is satisfactory,

place valve in its position in

rack and grind remaining

7010A

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |