|

|||

|

|

|||

|

Page Title:

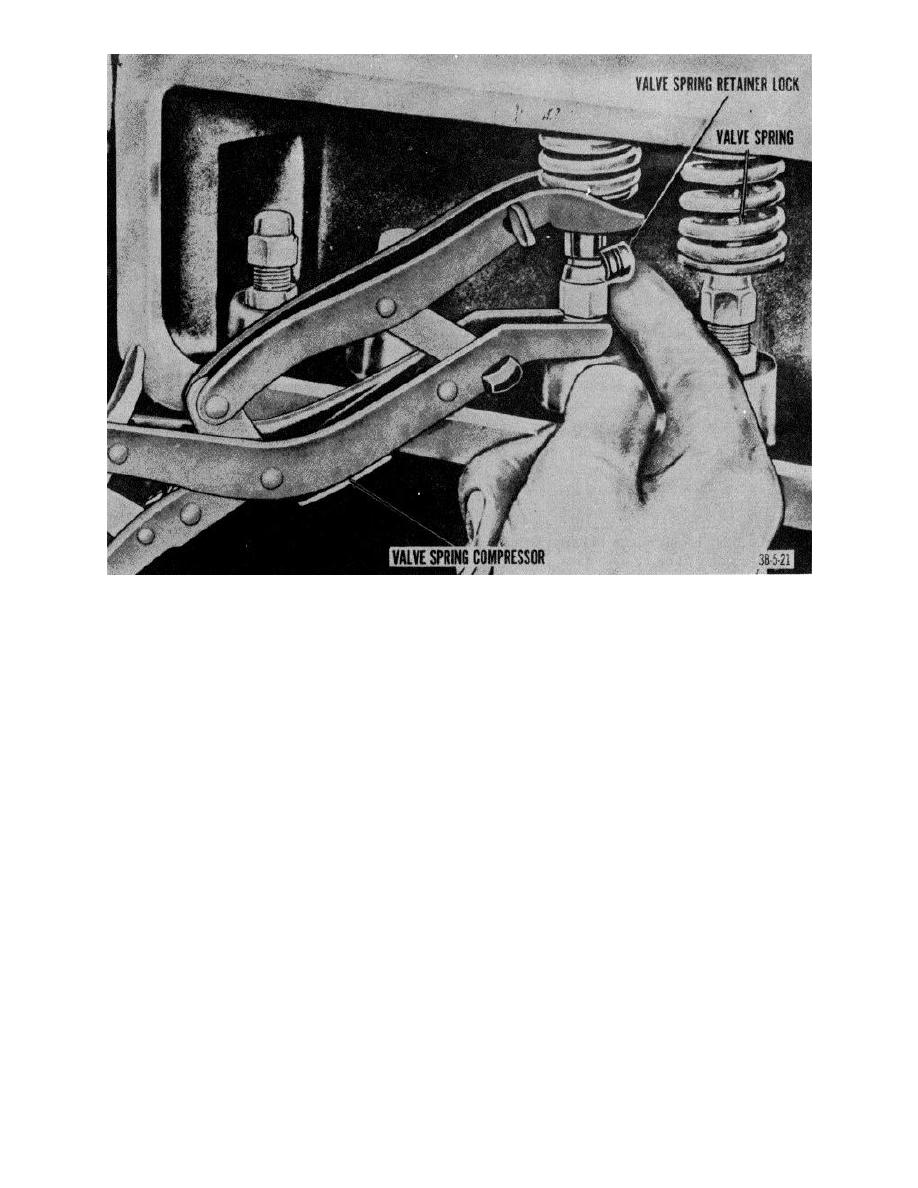

Figure 8. Compressing valve spring.. |

|

||

| ||||||||||

|

|

Figure 8. Compressing valve spring..

Then break the seat with a chisel and

A small amount of lubricant may be uaed to ease ine-

remove in two halve

tllstion.

Note

24. Exhaust Valves Seats.

a.

Inspection.

Do not permit drill to par through

(1) Remove valves (par. 22a).

seat and into counterbore of cylinder

(2) Be sure valve guide has been cleaned

block.

or replaced, as necessary (par. 23a).

(3) Inspect each exhaust valve meat for

c. Installation.

pitting, signs of fracture, and distortion

(1) Measure outer diameter of oversize

from valve pounding.

seat at room temperature and cut new

(4) Replace an exhaust valve seat that is

valve seat counterbore in cylinder

cracked, deeply pitted, or loose with a

block 0.0035 inch smaller in diameter

0.010 inch oversize meat, following

than seat to be installed, using a

instructions in b and c below.

valve seat cutting tool.

(2) Clean all cuttings from counterbore

b.

Removal

valve port and shrink oversize seat by

(1) Remove valve eat with a valve seat

chilling in dry ice for not less than 20

puller.

minutes

(2) If a pullet is not available, drill two

(3) After chilling, quickly drive seat into

opposing holes through the seat.

counterbore, using seat driving tool or

a soft-faced hammer.

AGO 7010A

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |