|

|||

|

|

|||

|

Page Title:

Table 13. Hydraulic System (Unit) Troubleshooting Procedures. |

|

||

| ||||||||||

|

|

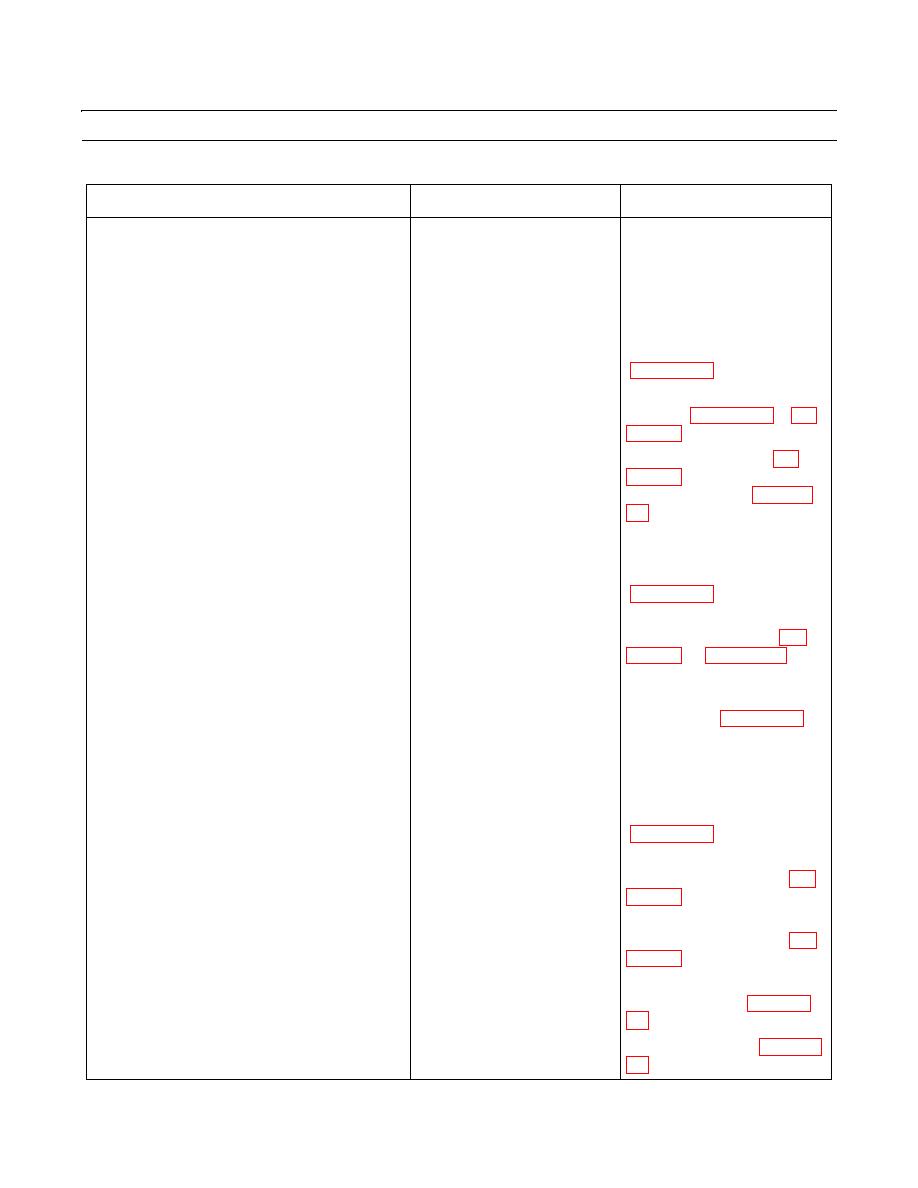

TM 10-3930-660-24-1

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

Table 13. Hydraulic System (Unit) Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Cold hydraulic oil.

Operate hydraulic system until

1.

Hydraulic Functions Operate Slowly.

hydraulic oil warms up (TM 10-

3930-660-10).

2. Engine speed too low.

Increase engine speed with

accelerator pedal (TM 10-3930-

660-10).

3. Check oil level.

Add hydraulic oil to proper level

4. Inspect hydraulic line(s) and

Replace hose(s) and tube(s) as

tube(s) for damage.

necessary (WP 0195 00 or WP

5. Check strainers and filter for

Repair or replace filter (WP

obstructions.

clean tank strainers (WP 0198

6. Check relief valve for

Inspect relief valve in system

defects.

with little or no pressure.

Replace relief valve if necessary

7. Check for worn or defective

Test pumps for proper operation

pumps.

and replace if necessary (WP

8. Check for proper hydraulic

Verify oil weight with oil

oil viscosity.

sample. If incorrect, drain

hydraulic tank (WP 0032 00).

Add correct oil.

Check for air leak in hydraulic

Operate hydraulic system, purge

2.

Hydraulic Functions Move Erratically.

system.

air from hydraulic circuits.

Check for leaks and loose

connections on pump inlet lines

1. Check for pinched or kinked

Replace pilot hoses as necessary

3.

Slow Boom or Extend Functions.

sections of pilot hoses.

from cab to control valve (WP

2. Check for defective

Replace hydraulic joystick

hydraulic joystick control

control valve if necessary (WP

valve.

1. Check for water in hydraulic

Determine where water entered

4.

Foamy Hydraulic Oil.

oil.

system. Change oil (WP 0032

2. Check oil level.

Add oil as necessary (WP 0011

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |