|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-34

9-8. Wheel Cylinder, Reassembly and Installation

9-7.

Wheel Cylinder, Cleaning, Inspection and

a. Reassembly. Reassemble the wheel cylinder in

Repair

reverse numerical sequence as illustrated in figure 9-2.

b. Installation. Refer to TM 10-3930-630-12 and

a. Wash all parts thoroughly in clean brake fluid.

install the wheel cylinder.

Use lint free cloth for cleaning.

b. Inspect all parts for wear, corrosion or other

damage that might impair cylinder action. Replace

unserviceable parts.

Section III. MASTER CYLINDER

9-10. Master Cylinder, Removal and Disassembly

9-9. Description

a. Removal. Refer to TM 10-3930-630-12 and

a. Brake cylinder and fluid reservoir are combined in

remove the master cylinder.

one casing and are joined by intake and by-pass ports

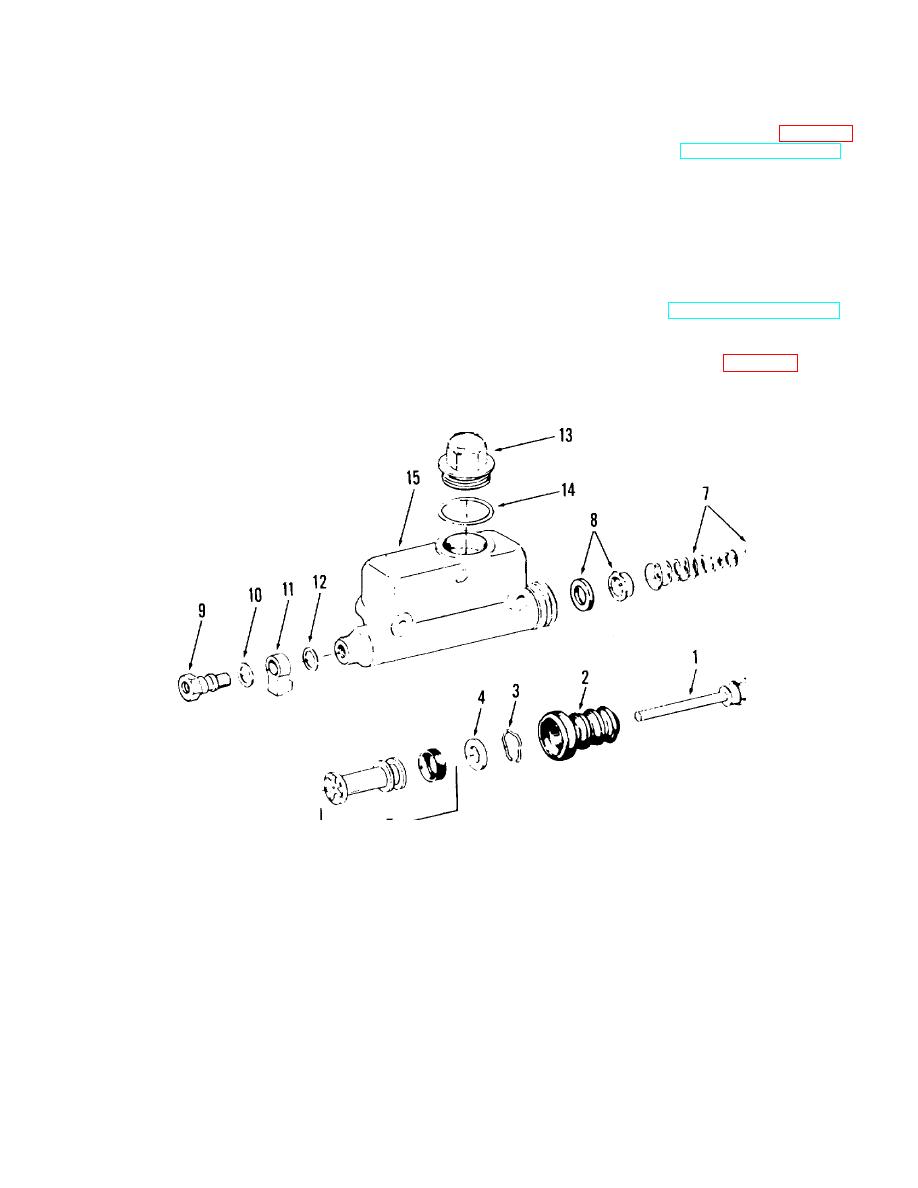

b. Disassembly. Disassemble the master cylinder in

located in the cylinder wall. Internal parts are removed

or installed at push rod end.

numerical sequence as illustrated in figure 9-3.

b. The cylinder piston is operated through a push rod

connected to the brake pedal.

1

Piston rod

6

Piston cup

11

Outlet fitting

2

Piston boot

7

Spring

12

Fitting gasket

3

Lock wire

8

Valve assembly

13

Filler cap

4

Stop plate

9

Fitting bolt

14

Cap gasket

5

Piston

10

Bolt gasket

15

Cylinder body

TA067429

Figure 9-3. Master cylinder, disassembly and reassembly.

pressure marks and discoloration.

Remove minor

9-11. Master Cylinder, Cleaning, Inspection and

marks and discoloration with crocus cloth.

Deep

Repair

blemishes will require reboring to resurface the cylinder

a. Use a lint free cloth and clean all internal parts in

wall. If resurfacing is necessary, use the following

clean hydraulic brake fluid.

procedure:

b. Clean cylinder casting in cleaning solvent, (Fed.

(1) Coat walls of cylinder bore with hydraulic

Spec. P-D-680). Finish cleaning with brake fluid to

brake fluid.

remove all traces of solvent.

c.

Inspect cylinder bore for deep blemishes,

9-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |