|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Remove the cylinder head from the engine

b. Cleaning and Inspection.

block, (TM 10-3930-627-12).

(1) Clean oil pump parts and screen with solvent

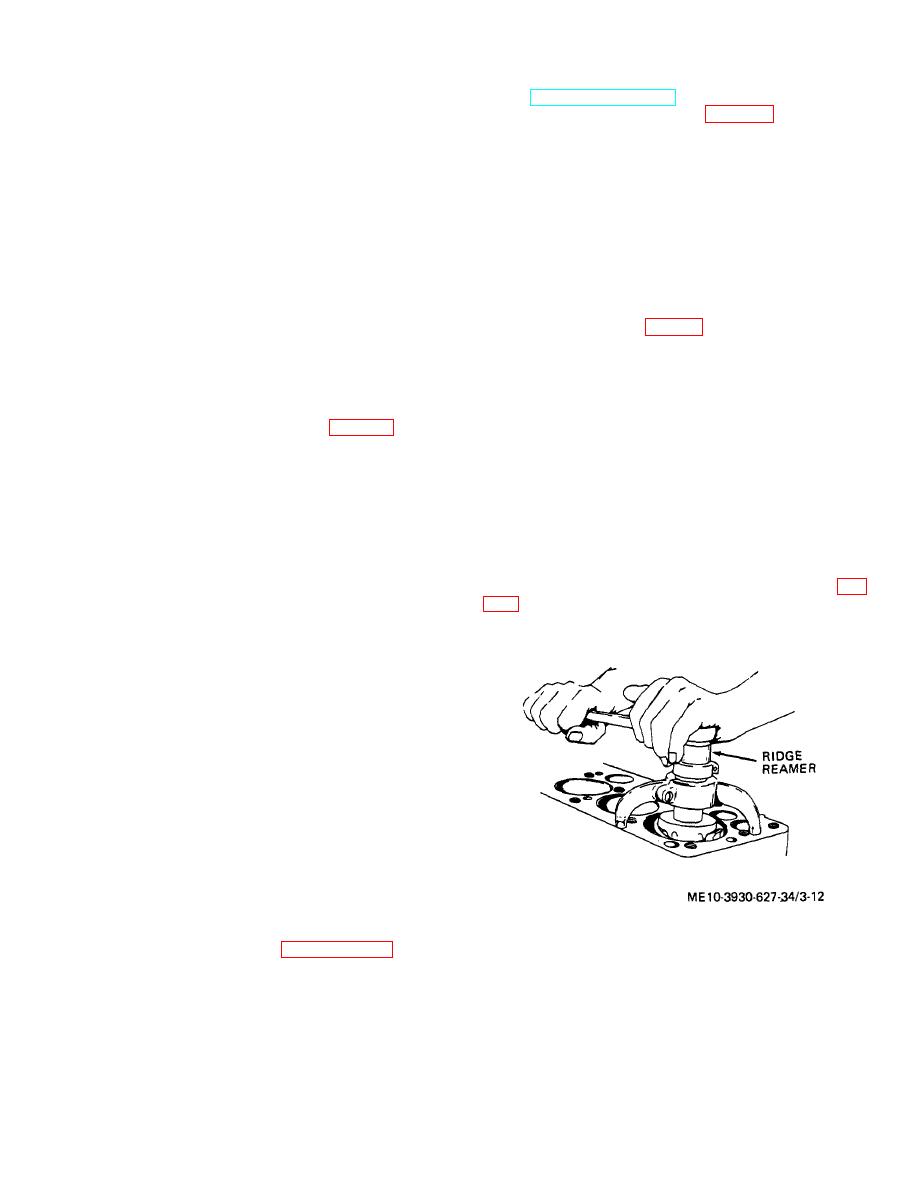

(3) Using a ridge reamer (fig. 3-12), remove the

and brush.

ridge from inside the top of the cylinder bore.

(2) Inspect pump gears and drive shaft. If pump

is defective, install a new pump.

(3) Inspect screen for holes and clean mesh. If

Note.

the mesh is defective, replace the screen with a

Ridge must be completely removed

serviceable one.

before trying to remove pistons to

(4) Thoroughly wet all parts of the pump with

avoid breaking rings and the piston

clean engine oil prior to installation to ensure that pump

lands

between

ring

grooves;

will operate immediately when starting engine.

however, do not cut deeper than

c. Installation. Reverse step a. above. If pump drive

worn part of cylinder wall.

slot does not engage distributor without turning rotor,

reengage gear teeth in different positions until oil pump

(4) Turn crankshaft throws to lowest points, and

is installed without changing ignition timing.

remove cotter pins (28, fig. 3-4) and nuts (27) from the

connecting rod bolts (26) and remove the lower bearing

3-11. Oil Pressure Relief Valve

caps and bearing halves (24) from the connecting rods

a. Removal.

(23).

(5) Push the connecting rods and pistons out of

carburetor.

the top of the cylinder bore.

(2) Remove relief valve plug (34, fig. 3-11), with

(6) Temporarily install the connecting rod bearing

gasket (33), from engine block (5). Remove gasket

caps on the connecting rods from which they were

from plug.

removed.

(3) Remove the adjusting washer (31) (if there is

(7) Using a ring spreader, remove the piston rings

one) from the plug.

(32) from the pistons (29), or simply break rings off, if

(4) Remove the spring (32) and valve (30) from

they will not be reused.

the port in the engine block. Remove washer from

(8) Remove the piston pin retaining rings (31) and

valve (if there is one).

remove the pins from the pistons, separating the

b. Cleaning. Clean all metal parts in solvent and dry

connecting rods from the pistons. Press the bushings

with compressed air or clean lint-free cloth.

(25) from the connecting rods, using new bushings (fig.

c. Inspection. Inspect the valve for scoring or pitting.

Inspect the spring for distortion.

operation.

d. Installation. Reverse step a. above, adding or

removing washers or installing new spring to obtain

desired pressure setting. Up to four washers are

permitted. The oil pressure relief valve setting is 25 to

35 psi with the engine oil at normal operation

temperature at governed speed.

3-12. Pistons, Connecting Rods and Rod Bearings

a. Description. Each piston has two compression

rings and two oil rings. The full floating piston pins are

held in place by retaining rings. The connecting rods

use babbitt lined sleeve bearing pairs. The connecting

rods and the connecting rod bearing caps are matched

and numbered.

Numbered sides must face the

camshaft when reinstalled. Never reverse or exchange

bearing caps.

b. Removal. To service pistons, rod and cylinders,

the engine need not be removed from the truck.

Figure 3-12. Reaming ridge from cylinder.

(1) Remove the oil pan. Paragraph 3-9 a. as

applicable.

3-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |