|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

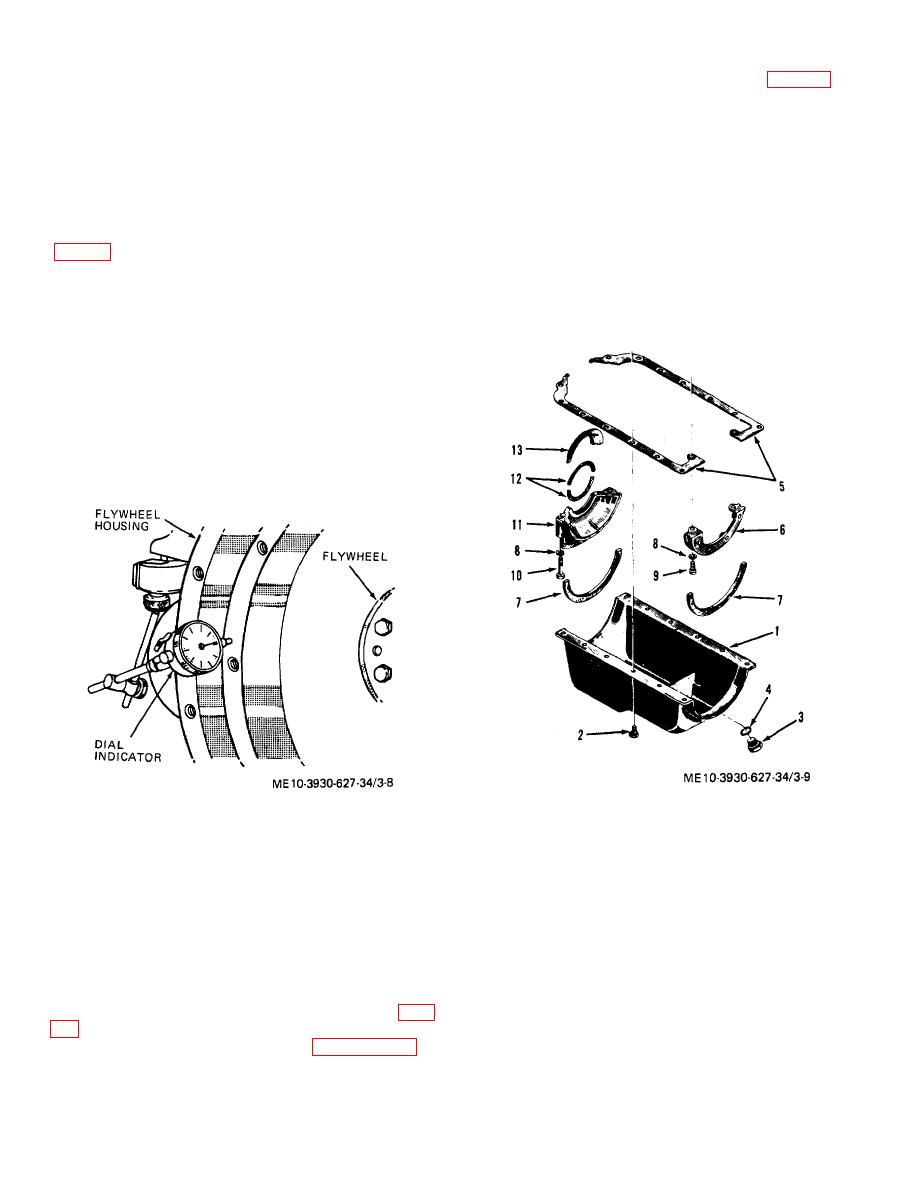

of 400 F (bluish color) and install ring gear on the rim of

(3) Remove attaching screws (2, fig. 3-9) and

the flywheel. Be sure beveled side of teeth is installed

remove oil pan. Scrape old gasket remains from pan

on correct side, so starter drive can enter.

and block.

(2) Flywheel installation.

Reverse removal

(4) Remove screws (9) and front filler block (6),

procedure in step a. above and torque flywheel nuts to

and filler block gasket (7).

35 to 40 foot-pounds.

(5) Remove screws (10) and rear filler block (11)

(3) To be sure that crankshaft flange has not

and gasket (7). Remove half of seal (12) from filler

been sprung or otherwise damaged or that counterbore

block. Remove gaskets from engine block.

in the flywheel, which locates it on crankshaft, is not

(6) Remove oil guard (13) by pushing it around

damaged, mount an indicator on the flywheel housing

crankshaft and out of engine block. Remove other half

of seal (12) from oil guard. Discard all used gaskets and

seals.

Note.

b. Cleaning. Clean oil pan and filler block with

When checking runout, remove spark

solvent and remove sludge and carbon from oil pan.

plugs to allow engine to be turned

Steam cleaning or a vapor degreaser will do a good job.

over freely.

(4) The indicator should be mounted to housing

so that it contacts the face of the flywheel, then turn the

flywheel at least one full revolution, at the same time

holding against the crankshaft to offset the possibility of

end play.

(5) Excessive runout of the flywheel (in excess of

0.008 inch) is probably caused by dirt in, or dam age to,

counterbore locating the flywheel on the crankshaft

flange.

1.

Oil pan

Figure 3-8. Checking flywheel runout.

2.

Scew and lock washer

3.

Magnetic plug

3-9. Oil Pan

4.

Plug gasket

To properly install a complete set of pan gaskets and

5.

Oil pan gasket

timing cover plate gasket, it will be necessary to remove

6

Front filler block

the engine. The timing gear cover plate cannot be

7.

Filler block gasket

removed for replacement of the timing cover plate

8.

Lock washer

gasket unless the engine is removed from the truck. For

9.

Front block screw

this reason maintenance of oil pump, pistons, rods, and

10.

Rear block screw

crankshaft bearings is normally performed with engine

11.

Rear filler block

removed from truck.

12.

Rear block seal

a. Removal (oil pan).

13.

Rear block oil guard

(1) Drain oil, and remove engine from truck, (para

2-6 a.)

Figure 3-9. Oil pan and seals, exploded view.

(2) Remove timing gear cover. Paragraph 3-7 a.

(1) thru (8).

3-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |