|

|||

|

|

|||

|

Page Title:

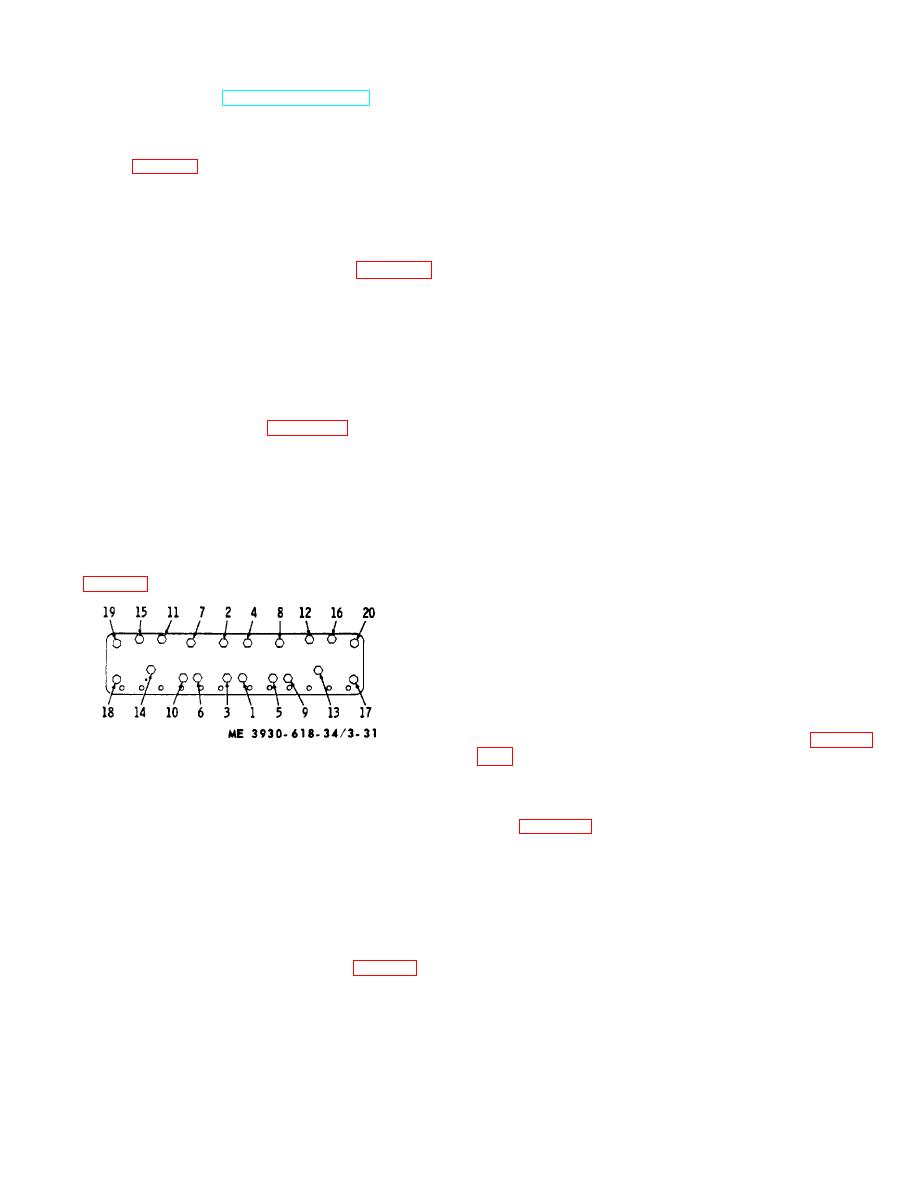

Figure 3-31. Sequence for cylinder head Capscrew tightening. |

|

||

| ||||||||||

|

|

(e) Remove spark plug cables.

3. Retighten capscrews in numerical

(f) Remove radiator connections to

sequence to full recommended torque.

4. Run

engine

until

coolant

engine and transmission (TM 10-3930-618-20).

temperature reaches minimum of 160F, (approx. 1

(g) Disconnect rocker arm oil feed line

from head and move out of way.

hour), then retorque capscrews to the full recommended

(h) Remove cylinder head capscrews

torque in the specified numerical sequence.

(11 and 16, fig. 3-30), nuts (5) and washers (6, 10, and

(g) Reset the valve tappet clearance.

17). Lift cylinder head assembly (19) from block with a

b. Cylinder Block and Cylinder Sleeves.

sling. Discard fire rings (23) and head gasket (24).

(1) Description. The cylinder block is a one-

(4) Inspection of cylinder head.

piece iron casting. Integral transverse members provide

(a) Clean cylinder head, removing all

rigidity and strength, assuring accurate alignment of

carbon deposits, and inspect for wear or other damage.

crankshaft bearings and cylinder sleeves. Block is bored

(b) Before removing valves (para 3-23)

to receive removable cylinder sleeves which are

check them for seating.

completely surrounded by full-length water jackets for

(c) Replace defective parts.

maximum cooling.

The main oil gallery extends

NOTE

lengthwise through the cylinder block, below and parallel

If cylinder head is to be replaced,

to the camshaft. Oil passages direct oil from main oil

parts from the defective head must

gallery to main bearings. A horizontal oil passage leads

to the outside of the cylinder block and is connected by

be thoroughly inspected before

tubing to lubricate rocker arm assembly. The removable

installing them in a new head. For

cylinder sleeves are made of alloy cast iron. Two

inspection procedures for valves and

silicone rubber packing rings, fitted into grooves in lower

rocker arm assembly (para 3-23) and

bore of cylinder block, prevent water leakage into

for spark plugs, see TM 10-3930-618-

crankcase. Sleeve is seated at top by a flange which fits

20.

into a machined recess in block. Cylinder head gasket

(5) Installation of cylinder head.

and fire rings are compressed between this flange and

(a) Thoroughly clean the top deck of the

cylinder head, holding sleeve in place.

cylinder block and the underside of the cylinder head.

(2) Removal of cylinder sleeve.

(b) Do not use any sealer or gasket

NOTE

dope on any part of the cylinder head gasket assembly.

When removing sleeves and pistons.

(c) Install guide studs in holes (19 and

do not interchange parts.

If any

20. fig. 3-31).

sleeves are to be reused, they should

be reinstalled in the same sleeve bore

from which the)y were removed.

Pistons must be reinstalled in the

same sleeves from which they were

removed.

If engine has already been removed from truck,

disregard (a) below.

(a) Remove engine from truck (para 2-

Figure 3-31. Sequence for cylinder head Capscrew

(b) Remove cylinder head assembly

tightening.

(para a above).

(c) Remove pistons and connecting

(d) Position the head gasket on the

rods (para 3-22).

cylinder block guide studs. Position the fire rings inside

(d) Rotate crankshaft to gain access for

the cylinder bores of the gasket and be sure no

installation of cylinder sleeve puller.

overlapping of the fire rings by the gasket occurs.

(3) Cylinder sleeve tool. Install puller tool to

(e) Carefully install the head, being sure

remove cylinder sleeve from top of cylinder block.

not to displace the positioned fire rings. Head is to be

NOTE

located by the guide studs. Install capscrews in all

If sleeve puller is not available, sleeves

locations except those occupied by guide studs.

may be loosened by placing end of

(f) Torque the capscrews to a final

hardwood block against bottom of sleeve

torque of 110 ft-lbs. in the following manner (fig. 3-31).

and striking block sharply with a

1. Tighten capscrews in numerical

hammer. Be careful not to hit cylinder

sequence to 1/2, final torque. Remove guide studs and

block.

install lifting studs when reaching these locations.

(4)

Cleaning and inspection of cylinder

2. Tighten capscrews in numerical

sleeves.

sequence to full recommended torque.

3-37

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |