|

|||

|

|

|||

|

Page Title:

Section III. LUBRICATION INSTRUCTIONS |

|

||

| ||||||||||

|

|

truck are listed and illustrated in TM 10-3930-624-20P

4-5.

Maintenance Repair Parts

(When printed).

Organizational maintenance repair

parts

for

the

Section III. LUBRICATION INSTRUCTIONS

b. Cleaning. Keep all external parts which do not

4-6.

General

require lubrication clean of lubricants. Before and after

This section contains lubrication

instructions

to

lubricating, clean all lubrication points.

supplement the lubrication order.

c. Points of Lubrication. Service the points of

4-7.

Detailed Instructions

lubrication at the required intervals. Refer to the current

lubrication order.

and store in a clean dry place away from external heat.

Prevent dust, dirt, and other foreign material from

contaminating the lubricant.

Section IV. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

4-8.

General

4-9

Preventive Maintenance Services

The truck must be systematically and periodically

Refer to table 4-1 for preventive maintenance services.

inspected for defects to ensure that it is ready for

Item numbers indicate a sequence for performing

operation at all times. Defects should be corrected

preventive checks and services.

before they result in serious damage or failure.

Section V. TROUBLESHOOTING

of probable causes and possible remedies. Refer any

4-10. General

trouble beyond the scope of organizational maintenance

to direct support maintenance.

correcting improper operation or failure of the truck

components. Each trouble symptom is followed by a list

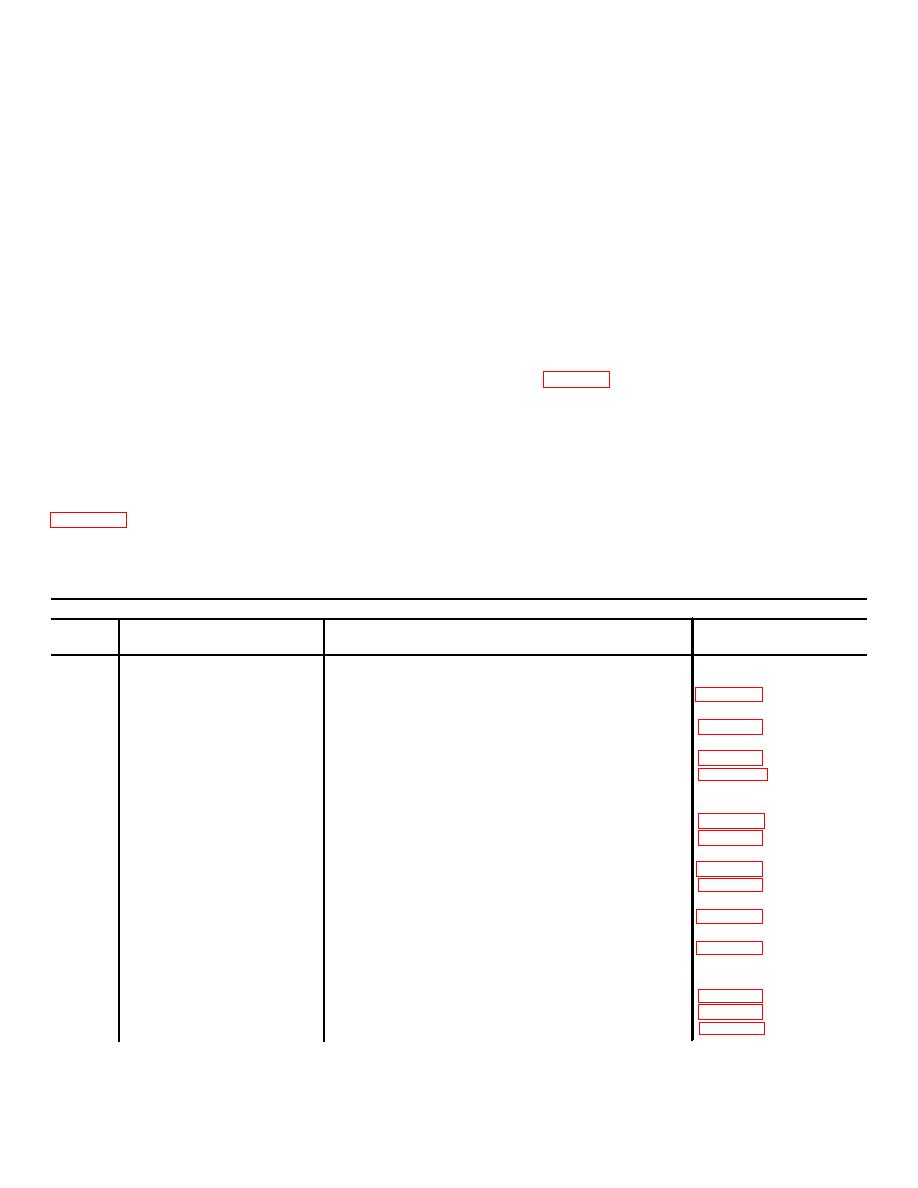

Table 4-1. Preventive Maintenance Checks and Services

Operator Maintenance Category

Schedule per 250 hours of operation

Item

Item to be

number

inspected

Procedure

Reference

1

Alternator and fan belt tension

Check that belt can be deflected inch inward midway

between the fan pulley and the alternator pulley.

2

Cooling system

Check level and antifreeze qualities of coolant. Check for para 4-28

damage or leaking hoses.

3

Fuel filter

Service fuel filter

4

Fuel lines and fittings

Check for leaks.

5

PCV valve

Clean PCV valve and fittings.

6

Battery and cables

Check electrolyte level. Check for cracked or leaking

battery, loose or corroded terminals, loose cables.

Correct faulty conditions.

7

Hydraulic reservoir breather

Replace if clogged or dirty.

8

Hyrdaulic system

Check for leaks, damaged lines and fittings, and low

fluid level. Correct any deficiencies.

9

Brake pedal free travel

Adjust if brake pedal does not have inch free travel.

10

Brake application

Correct deficiencies if brake application is spongy,

ineffective, or nonexistent.

11

Tires

Check for embedded glass and metal, cuts, gouges, and para 4-55

other damage.

12

Intake and exhaust manifold

Check for cracks, leaking gasket, and insecure mounting. para 4-18

*13

Exhaust system

Replace damaged parts.

*14

Engine tuneup and test

Check engine compression and timing.

*15

Electrical system

Check and adjust electrical components including

alternator, voltage regulator, starter, and distributor.

16

Battery

Check and service battery.

*To be accomplished after every 500 hours of operation instead of every 250 hours of operation.

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |