|

|||

|

|

|||

|

Page Title:

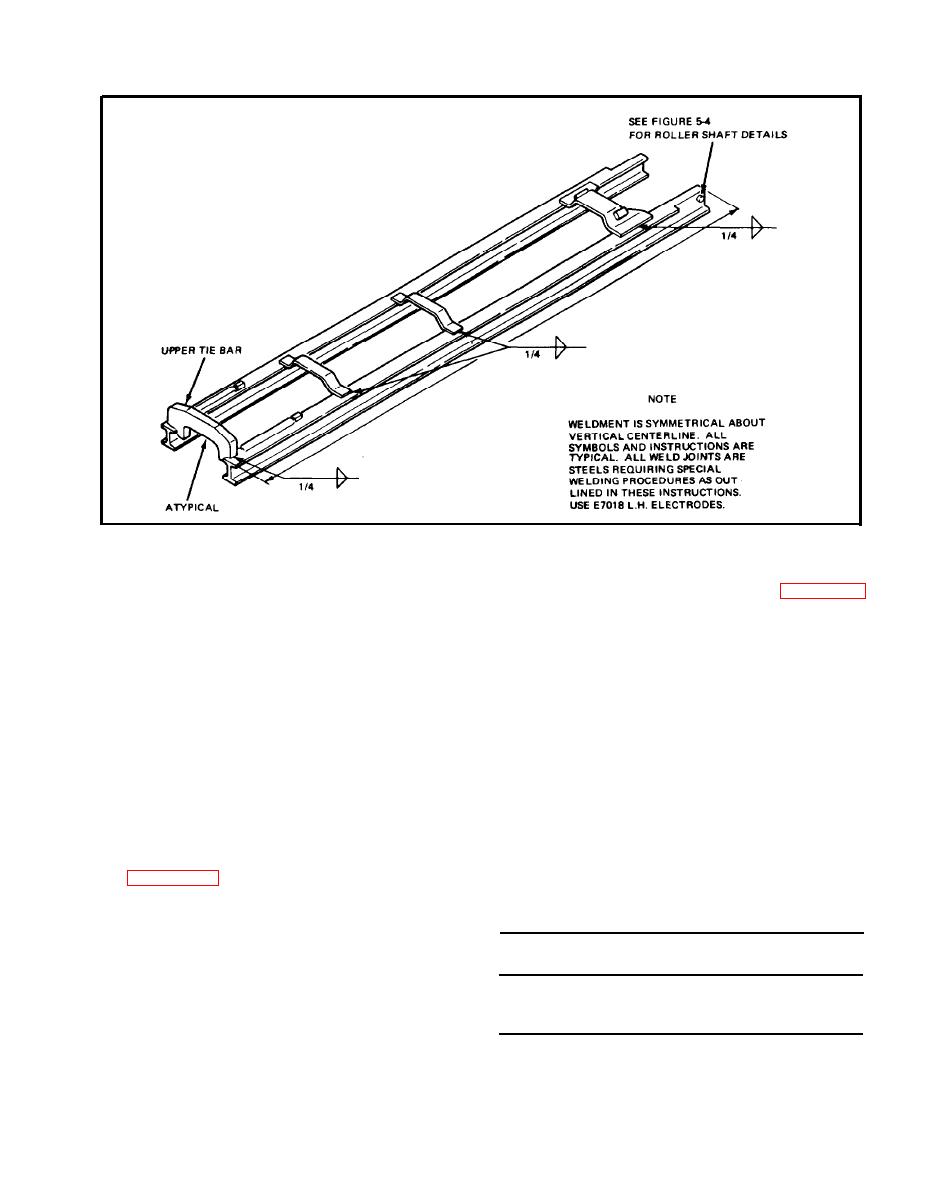

Figure 5-5. Welding Repair of Inner Rail Assembly |

|

||

| ||||||||||

|

|

Figure 5-5. Welding Repair of Inner Rail Assembly

for chill cracks. If any, prepare as in paragraph

joints. It will be obvious that the selection of

5-19 (above) and reweld.

electrode sizes under 5/32" is unwise for this

application.

b. Joint inspection is recommended by either of

the following methods:

f. All joints calling for 3/8" (or more) fillet must

be made in 2 or more passes. Bead from first pass is

1. Dye penetrant, wet or dry process.

t o be chipped and work must not be allowed to

cool between passes.

2. Magnetic particle inspection. Manufacturer's

instructions included with the testing gear should

g. Welding on fork assemblies or upright

be followed as applied to the size, shape, or other

m e m b e r s usually involves material with up to

nature of the work being tested. In general,

0.45% Carbon. Two-pass welding with slag removal

however, the conditions shown below will serve in

between passes allows one pass to act as additional

most cases, whether the process employs direct or

preheat or post heat to the other pass. The

rectified current.

heat-affected zone hardness will be kept low and

safe in this manner.

(a) Distance between prods shall not be less

than 2 inches.

h. Figures 5-1 thru 5-5 illustrate points of weld

and proper weld symbols for the types of weld to

( b ) Ratio for prod spacing/amperage/section

be used in each case when welding on carriage and

thickness:

upright parts.

Thickness

Thickness

5-21. INSPECTION.

Under 3/4"

over 3/4"

Spacing

2 " to 4 "

2 0 0 - 3 0 0 amps

a. Remove slag and spatter, and check for

3 0 0 - 4 0 0 amps

4 " to 6 "

3 0 0 - 4 0 0 amps

c o n f o r m i t y to paragraph 5-20 (above). Finished

400-600 amps

6 " to 8 "

400-600 amps

and cooled joints should be thoroughly inspected

600-800 amps

5-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |