|

|||

|

|

|||

|

Page Title:

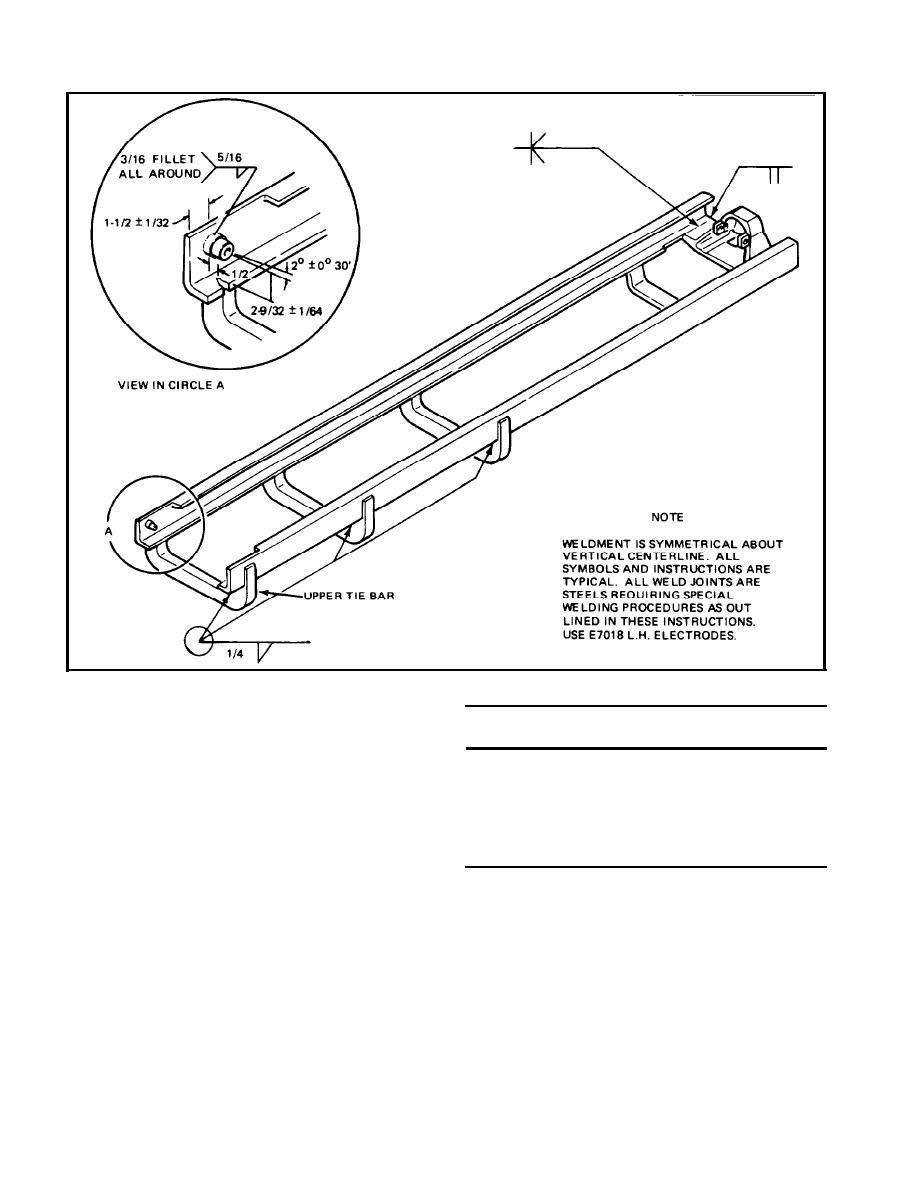

Figure 5-4. Welding Repair of Outer Rail Assembly |

|

||

| ||||||||||

|

|

Figure 5-4. Welding Repair of Outer Rail Assembly

required, a disc grinder with #80 grit abrasive is

Weld Inches/Min.

recommended.

Size

Amperage

(Average)

-

3/32

70-120

5-20. WELDING.

100-150

6-8

1/8

5/32

120-200

8-10

a. Welding should be performed by experi-

3/16

200-275

10-12

enced/qualified welders.

7/32

275-350

12-14

300-400

14-16

l/4

b . Voltage/amperage/speed settings should be

b a l a n c e d to produce a well-formed bead, and to

These ranges must be balanced per (b.) above.

assure proper penetration.

d . On the rectifier type welders (most common

today) the voltage is variable and is automatically

c. For subject component welding, the following

keyed to the amperage. The voltage range is there-

ranges apply for E-7018, E-8018, E-9018, and

fore omitted from the listing.

E-10018 electrodes:

Manufacturers

recom-

mendation for arc length and amperage is to be

e. Average welding speed (inches per minute) is

followed.

b a s e d on l/4" fillets and on flat and horizontal

5-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |