|

|||

|

|

|||

|

Page Title:

Figure 4-45. Breaker Point Inspection |

|

||

| ||||||||||

|

|

Figure 4-45. Breaker Point Inspection

d. After an adjustment has been made to one

spring, check the minimum advance point again.

e. Operate the distributor at the specified RPM

to give an advance just below the maximum. If this

advance is not to specifications, stop the

distributor and bend the other spring bracket to

give the correct advance.

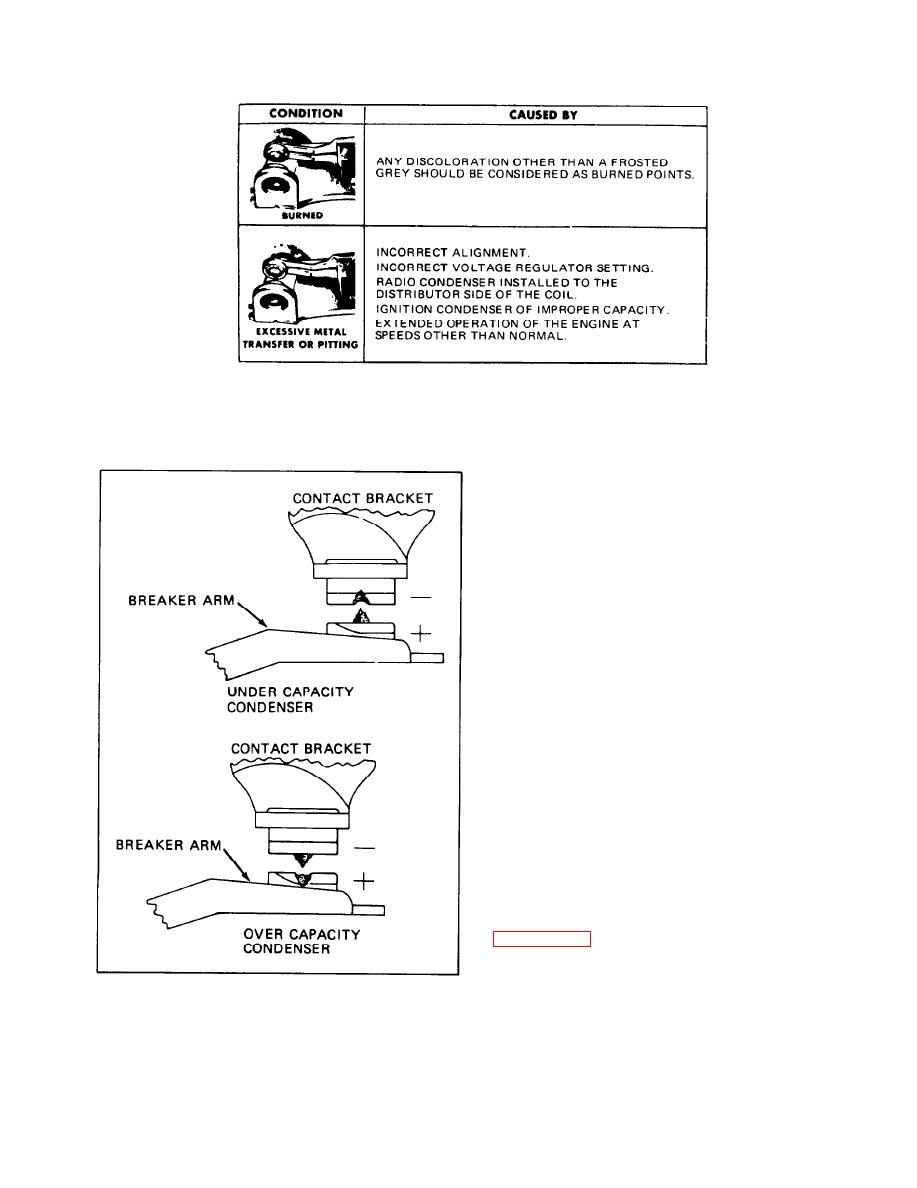

4-46. BREAKER POINT INSPECTION. During

the tune-up procedure, breaker points should be

examined as outlined below, aligned and/or

replaced, as necessary.

a . If points are pitted, burned or worn to an

unserviceable condition, install a new set of points.

b. The normal color of contact points should be

a light gray. If the contact point surfaces are black,

it is usually caused by oil vapor, or grease from the

cam. If they are blue, the cause is usually excessive

heating due to improper alignment, high resistance

or open condenser circuit.

c. Badly pitted points may be caused by a

defective or improper condenser capacity. See

d. If the condenser capacity is too high, the

crater (depression) will form in the positive

Figure 4-46. Breaker Point Metal Transfer

contact. If the condenser capacity is too low, the

4-35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |