|

|||

|

|

|||

|

Page Title:

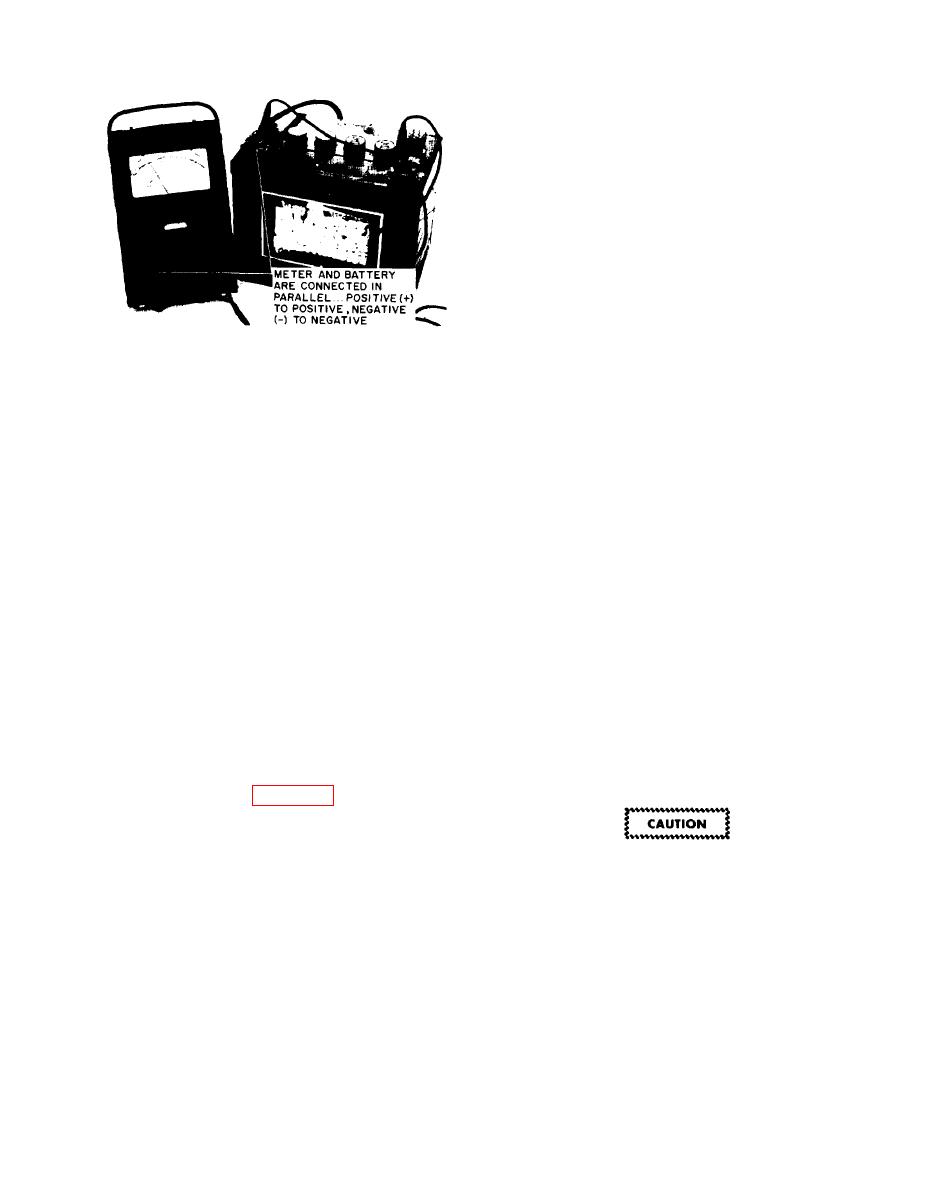

Figure 4-39. Battery Test Hook-up |

|

||

| ||||||||||

|

|

read 12+ volts. If reading is below 12 volts, battery

is defective or under-charged.

f . Reconnect coil wire to distributor, and start

and accelerate the engine to obtain a reading of

alternator output. Charging system output should

be at least 12-l/2 volts. If not at least 12-l/2 volts,

then the problem is in the charging system.

4-36. ENGINE PERFORMANCE CHECK. At

l000-hour

maintenance

interval,

every

the

following check of engine performance should be

made to determine whether engine is in need of a

tune-up or is out of adjustment.

Figure 4-39. Battery Test Hook-up

a. Before making check, run engine until unit is

at operating temperature. This is important as the

transmission oil temperature should be 200 degrees

and the difference between highest and lowest cell

F. and the engine water jacket should be at

is less than 0.05 volt, battery is good but requires

operating temperatures. Apply parking brake.

charging.

b . With the engine operating at idle and the

f. If any cell reads 1.95 volts or more and there is

transmission in NEUTRAL, check the fluid level

a difference of 0.05 volt or more between the

on the dipstick. Fill if necessary to the FULL mark

highest and lowest cell, the battery is defective.

on the dipstick, using Type "A", Suffix "A"

Automatic Transmission Fluid (Clark Part Number

g. If all cells read less than 1.95 volts, battery is

879803; fluid containers must display a

too low to test accurately. Boost-charge and repeat

qualification number prefixed by "AQ-ATF").

light load test.

c. With a tachometer, check engine for governed

4-35. STARTING/CHARGING SYSTEM TESTS.

speed at full throttle. The unloaded engine RPM

The following test will help in localizing any

should be set at 2350.

problem within the alternator, starter or battery.

d. Check the governed engine speed with partial

a. Disconnect the high tension coil wire from the

load. With engine at full throttle and the tilt lever

distributor cap. Clip a jumper lead onto the coil

i n full backward tilt, momentarily hold the tilt

wire terminal and ground the jumper to the engine

l e v e r back to load the engine. With the engine

block or ground strap.

l o a d e d in this manner, the approximate engine

RPM should be 2200.

b. Hook up a voltmeter across the battery

terminals as shown in figure 4-39.

c. Depress the accelerator pedal fully (to obtain

higher compression) and crank the engine over by

Prolonged stalling of the converter can

engaging the starter for a few seconds, while

c a u s e internal damage to the converter.

observing voltmeter reading.

Stall converter only long enough to attain

the peak RPM reading - maximum 30

d. During cranking, voltmeter should read at least

seconds.

9.6 volts. If reading is low, a problem exists in the

cranking system (battery, starter, or cables).

e. With a capacity load on the forks, check for

normal stall RPM by positioning machine against

e. Immediately after cranking, voltmeter should

4-29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |