|

|||

|

|

|||

|

Page Title:

Table 3-3. Main Bearing Shell Dimensional Data |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

h. Installation of Crankshaft and Main Bearings.

heating (fig. 3-136). If any of these defects are pres-

(1) If a new crankshaft is to be installed, steam

ent, the bearings must be replaced.

clean it to remove the rust preventive, blow out the oil

NOTE

passages with compressed air and install the plugs.

Since the lower main bearing shells carry the

Then, install the crankshaft as follows:

crankshaft load, their condition will normally

NOTE

indicate the need for replacement.

When a new or reground crankshaft is in-

Babbitt plated bearings may develop minute

stalled, new main and connecting rod (upper

cracks or isolated cavities. These are not

and lower) bearing shells and new thrust

detrimental to engine operation and are not

washers shall also be installed.

justification for bearing replacement.

(2) Install the upper grooved bearing shells in the

(21) Inspect the backs of the shells for bright

block. If the old bearing shells are to be used again, in-

spots which indicate they have been moving in the cap

stall them in the same locations from which they were

or cylinder block. If such spots are present, discard the

removed.

shells.

(3) Apply clean engine oil to all crankshaft jour-

(22) Measure the thickness of the shells at point C

nals and install the crankshaft in place so that the tim-

ing marks on the crankshaft timing gear and the idler

illustrated in figure 3-138.

gear match.

(23) The minimum thickness of a worn standard

(4) Install the upper halves of the crankshaft

main bearing shell is 0.123 inch. If any of the shells

thrust washers on each side of the rear main bearing

are thinner than this dimension, replace all shells.

support and the doweled lower halves on each side of

Table 3-3 lists the minimum bearing shell thickness

the rear main bearing cap. The grooved side of the

for a new standard and undersize bearings, and the

thrust washers must face toward the crankshaft thrust

crankshaft main bearing journal diameters corre-

surfaces (fig. 3-131).

sponding to each bearing size.

NOTE

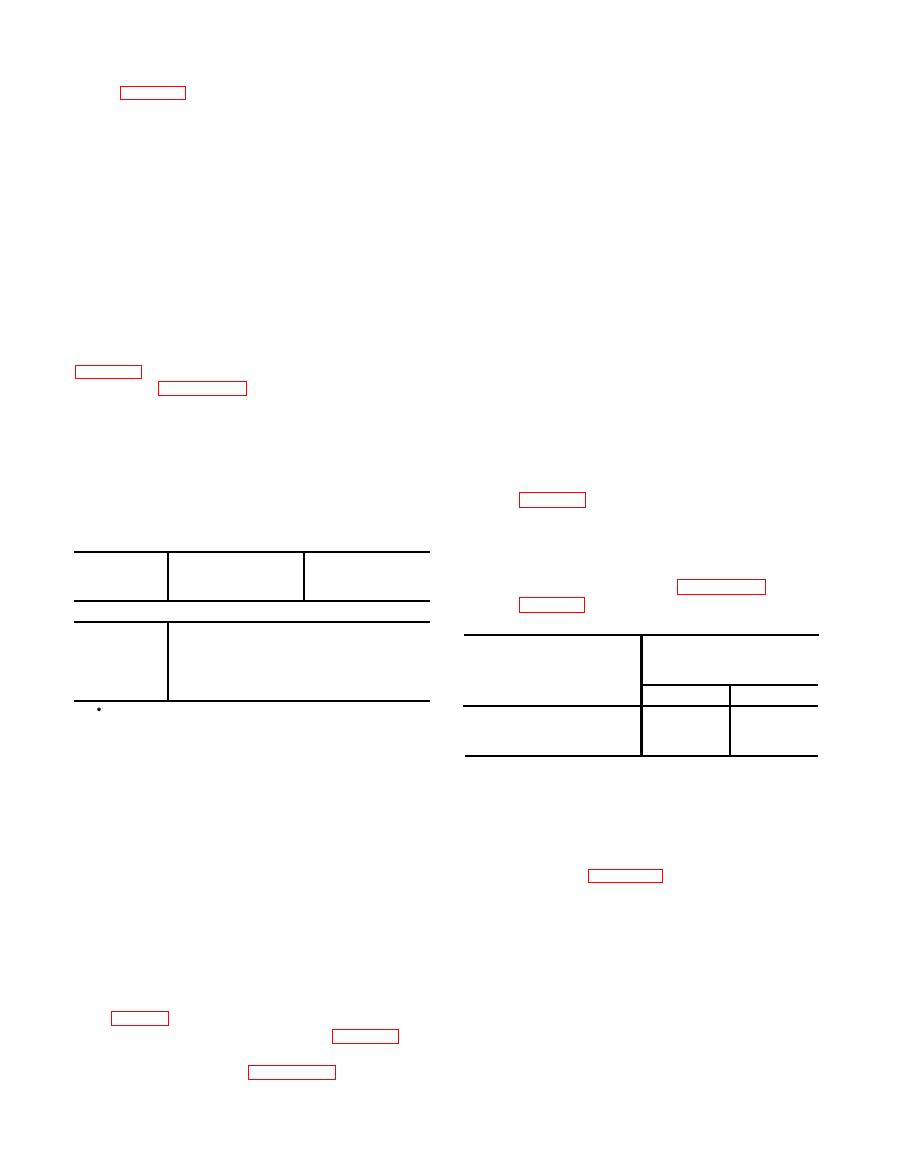

Table 3-3. Main Bearing Shell Dimensional Data

If the crankshaft thrust surfaces were re-

ground, it may be necessary to install over-

Nominal size

Minimum new bearing

Crankshaft main

size thrust washers on one or both sides of the

shell thickness

of bearing

Bearing journal dia.

rear main journal. Refer to figure 3-135, D

(inches)

(inches)

(inches)

and table 3-4.

In-line Engines

.1245

2.999-3.000

Standard

Thrust washer

.1255

2.997-2.998

.002 Undersize

Nominal

thickness

.010 Undersize

.1295

"2.989-2.990

size

(inches)

.020 Undersize

.1345

`2.979-2.980

(inches)

,030 Undersize

.1395

`2.969-2.970

Mm.

Max.

Dimension of reground crankshaft

.1190

.1220

Standard

.1270

.005 Oversize

.1255

(24) Measure the clearance between main bear-

.1320

.010 Oversize

.1300

ings and crankshaft journals. If the crankshaft is in

(5) Install the lower bearing shells (no oil grooves)

place, measure the clearance with a soft plastic meas-

in the bearing caps, If the old bearing shells are to be

uring strip forced between the journal and bearing. If

used again, install them in the same bearing caps from

the clearance is, or exceeds 0.006 inch, replace all bear-

which they were removed. Lubricate the bolt threads

ing shells. With new shells, the clearance should be

and bolt head contact surfaces with a small quantity of

0.0010 to 0.0040 inch.

International Compound No. 2, or equivalent. Draw

(25) If the crankshaft is removed, install the bear-

the bolts up snug (fig. 3-129). Then, rap the caps

ing shells in the block. Replace bearing caps and

sharply with a soft hammer to seat them properly.

torque bearing cap bolts to 120-130 lb-ft. Measure in-

(6) Draw the bearing cap bolts uniformly tight,

side diameter of bearings and compare with crank-

starting with the center cap and working alternately

shaft main bearing journal diameters as listed in table

toward both ends of the block, to 120-130 lb-ft torque.

3-3. The tolerances specified in (24) above apply.

Rotate the crankshaft to make sure that it rotates free-

g. Reassembly.

ly.

(1) Install plugs in crankshaft, if removed.

NOTE

(2) Install the oil pump drive gear on the crank-

If the bearings have been installed properly,

shaft (fig. 3-99).

the crankshaft will turn freely with all of the

(3) Position timing gear key (17, fig. 3-130) in

main bearing cap bolts drawn to the specified

keyway of crankshaft and drive the timing gear (18) on

torque.

the crankshaft as shown in figure 3-139.

3-86

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |