|

|||

|

|

|||

|

Page Title:

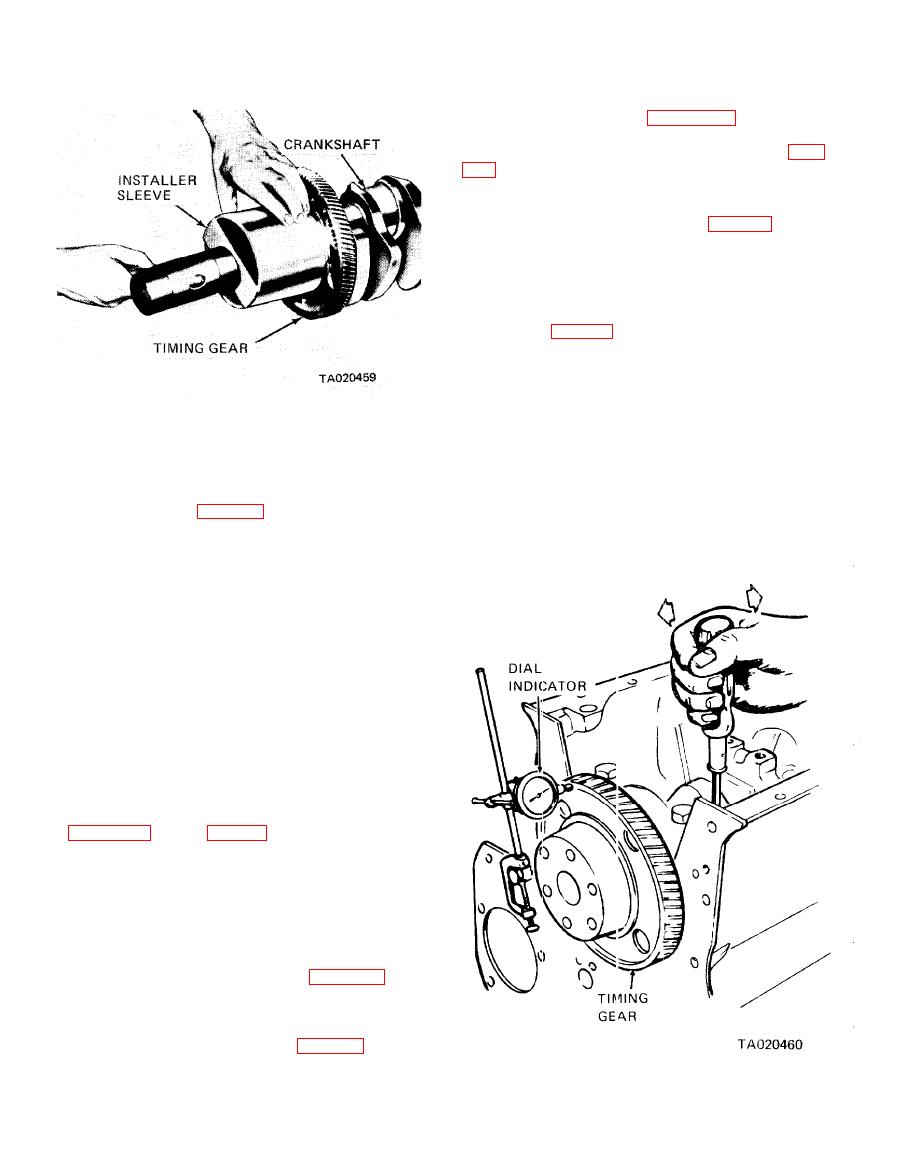

Figure 3-139. Crankskuft timing gear installation. |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

(b) Place the ring compressor on a wood block,

tapered end up, as shown in figure 3-145.

(c) Stagger the piston ring gaps and make sure

the oil control ring expanders are not overlapped (para

(d) Start the top of the piston straight into the

ring compressor; then, push the piston down until it

contacts the wood block (operation 1, fig. 3-145).

(e) Note the position of the matchmark made on

the liner and place the 1 mer on a wood block.

rod assembly on the liner, so the number on the rod

and cap are alined with the matchmark on the liner

(operation 2, fig. 3-145).

NOTE

The numbers, or number and letter, on the

side of the connecting rod and cap identify

the rod with the cap and indicate the particu-

lar cylinder in which they are used. If a new

connecting rod is to be installed, the same

identification number, or number and letter

(5) After honing, the liner must conform to the

must be stamped or etched in the same loca-

same limits on taper and out-of-round as a new liner,

tion as on the connecting rod that was re-

and the piston-to-liner clearance must be within speci-

placed.

fied limits listed in table 1-1.

(g) Push the piston and rod assembly down into

(6) Discard and replace the seal rings. Replace a

the liner until the piston is out of the ring compressor.

defective liner.

(7) Wipe the inside and outside of the cylinder

liner clean. Make sure the block bore and counterbore

are clean so the liner flange will seat properly.

e. Installation.

(1) Fit Liner in Bore.

(a) Slide the liner into the block until the flange

on the liner rests on the bottom of the counterbore in

the block.

CAUTlON

Do not drop or slam the cylinder liner flange

against the counterbore in the block.

(b) Tap the liner lightly with a soft hammer to

make sure the liner seats in the bottom of the counter-

bore.

(c) Clamp the cylinder liner in place as shown in

tance from the top of the liner flange to top of the

block with a dial indicator.

(d) Matchmark the liner and block with a chalk

or white paint so the liner may be reinstalled in the

same position and in the same bore. Place the match-

mark on the outer edge of the engine serial number

side.

cylinder liner from the block.

(2) Install Piston, Connecting Rod and Liner.

(a) With the piston assembled to the connecting

rod and the piston rings in place (para 3-34) apply a

clean coat of engine oil to the piston, rings and inside

of piston ring compressor tool.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |