|

|||

|

|

|||

|

Page Title:

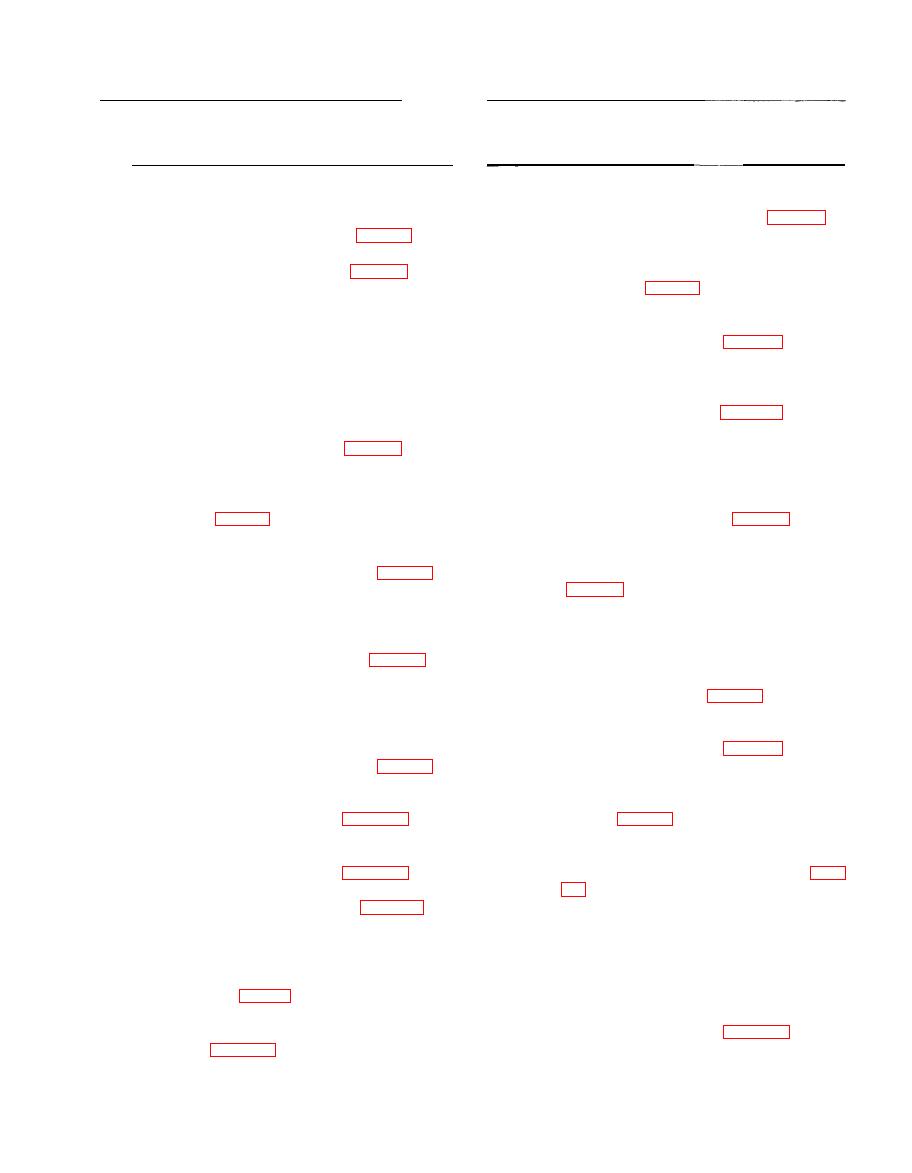

Table 2-2. Troubleshooting - Continued |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

Table 2-2. Troubleshooting -- Continued

Table 2-2. Troubleshooting - Continued

MALFUNCTION

MALFUNCTION

TEST OR INSPECTION

TEST OR INSPECTION

CORRECTIVE ACTION

CORRECTIVE ACTION

18.

HYDRAULIC VALVES WILL NOT HOLD.

12.

ENGINE GENERATOR OVERHEATS,

Step 1. Check for scored valve spool.

Step 1. Check for grounded or shorted arma-

Replace defective valve spool (para 6-2 or

ture.

6-4).

Replace defective armature (para 3-7).

Step 2. Check for dirt or foreign matter in

valve.

Replace defective bearings (para 3-7).

TRANSMISSION AND TORQUE CONVERT-

Clean valve (para 6-2 or 6-4).

13.

ER OVERHEATS.

S t e p 3. Check for weak or broken detent

spring.

Step 1. Check follow oil level.

Service per lubrication order.

Replace defective spring (para 6-2).

Step 2. Check followcoolant level irradiator.

19.

TRUCK LOSES FOUR WHEEL DRIVE.

Refill with coolant to proper level.

Step 1. Check for defective or wrongly adjust-

ed transmission control cable.

Step 3. Check for aerated oil (foaming).

Drain and refill. Refer to lubrication order.

Adjust or replace cable (para 4-11).

Step 4. Check for clogged or dirty oil cooler.

Step 2. Check for defective shifter coupling.

Clean or replace oil cooler (para 3-5).

Replace defective shifter coupling (para

14.

TRUCK MOVES IN ONE DIRECTION ONLY.

5-8).

DIFFERENTIALS EXCESSIVELY NOISY.

20.

Step 1. Check for defective control valve.

Repair or replace transmission control

Step 1. Check for broken or worn bearing.

valve (para 4-7).

Replace defective bearing (para 5-7).

Step 2. Check for defective pinion and ring

Step 2. Check for transmission clutch slippage

by checking clutch pressures.

Replace defective ring and pinion gear

Repair or replace transmission (para 4-9).

15.

ENGINE RUNS BUT TRUCK WILL NOT

MOVE.

TRANSMISSION MAIN PRESSURE LOW.

21.

Step 1. Check control valve for proper adjust-

Step 1. Check for low oil level.

ment.

Add oil if low. Refer to the lubrication or-

Adjust or repair control valve (para 4-7).

der.

Step 2. Check for defective torque converter.

Step 2. Check for clogged strainer screen.

Repair or replace torque converter (para

Clean strainer screen (para 4-9).

4-5).

Step 3. Check for defective main pressure reg-

Step 3. Check for defective transmission as-

ulator spring.

sembly.

Replace defective spring (para 4-2).

Repair or replace transmission (para 4-9).

Step 4. Check for main pressure regulator

valve sticking open.

16.

STEERING HYDRAULIC CYLINDER LEAKS.

Rebuild main pressure regulator body as-

Step 1. Check for worn or damaged packing.

Replace defective packing (para 5-15).

sembly (para 4-2).

Step 5. Check for clutch cutoff valve sticking

Step 2. Check for cracked or broken cylinder

housing.

open.

Replace defective housing (para 5-15).

Rebuild control valve body assembly (para

Step 3. Check for scored piston rod.

Step 6. Check for aerated oil (foaming).

Replace defective piston rod (para 5-15).

Oil level high, or of improper grade. If

HYDRAULIC SYSTEM LOSES PRESSURE.

17.

high, drain to proper level. If improper

Step 1. Check for defective hydraulic control

grade, drain and fill. Refer to the lubrica-

valve.

tion order.

Repair or replace defective hydraulic con-

Step 7. Check for worn or damaged converter

trol valve (para 6-2, 6-3, 6-4, or 6-8).

charging pump .

Step 2. Check for defective hydraulic pump.

I f damaged, rebuild (para 4-3).

R e p a i r or replace defective hydraulic

pump (para 6-14 or 6-15).

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |