|

|||

|

|

|||

|

Page Title:

Section VI. INTAKE AND EXHAUST VALVES |

|

||

| ||||||||||

|

|

TM 10-3930-632-34

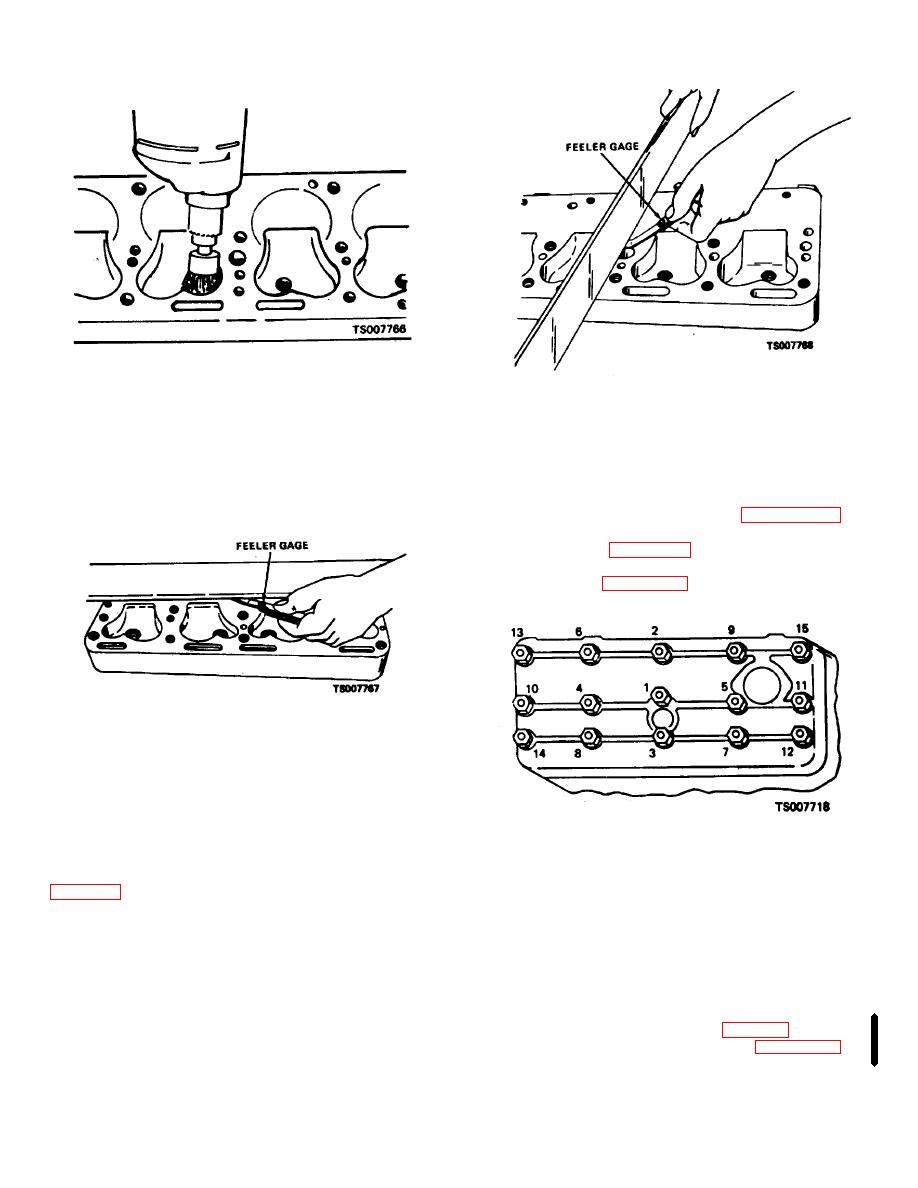

Figure 9-2. Cleaning Carbon From Combustion

Figure 9-4. Checking Cylinder Head Flatness Crosswise.

Chamber.

9-8.

Repair

b.

Clean the cylinder head thoroughly with a

Repair consists of replacement of a defective or,

solvent or degreasing solution and blow it off with air

otherwise unserviceable cylinder head.

pressure.

c.

Make sure that gasket contact surfaces on the

9-9.

Installation

head and block are clean, smooth and flat. See figure 9-

Reverse the procedures outlined in paragraph 9-6 for

3.

cylinder head installation.

a.

Refer to table 9-2 for fasteners torque

specifications.

b.

Refer to figure 9-6 for cylinder head bolt

tightening sequence.

Figure 9-3. Checking Cylinder Head Flatness

Lengthwise.

d.

Check out-of-flatness with straightedge and

feeler gage; maximum permissible is .00075 inches per

inch of width or length. Thus, for a cylinder head 16"

long, maximum permissible lengthwise out-of-flatness is

.012". Out-of-flatness should vary gradually and

Figure 9-5. Cylinder Head Bolt Tightening Sequence.

uniformly from end to end and side to side. Localized

depressions or high spots should not exceed .003 See

Section VI. INTAKE AND EXHAUST VALVES

exhaust valves seat in shrink-fit valve seat inserts in the

9-10.

General

block.

The intake and exhaust valves of this L-head engine

9-11.

Removal

are mounted in the cylinder block. They are opened by

operation of the camshaft through adjustable valve

a.

Remove the cylinder head (para 9-6).

tappets. They are closed by the valve springs. The valve

b.

stems ride in valve guides which are pressed into the

Remove the valve tappet cover (para 9-13.1).

block. The intake valves seat directly in the block. The

Change 1 9-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |