|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-12

c.

Installation.

breather and clean in cleaning compound, solvent (Fed.

Spec. P-D-680) and dry thoroughly. Install breather

(1) Install cross assemblies (3, Fig. 4-79) on

and tighten securely.

drive shaft (4) and secure with screws (2). Tighten

c. Lubrication

screws to a torque of 25 to 30 pound-feet (338 to 40.6

N.m) dry or 20 to 24 pound-feet (27.1 to 32.5 N.m)

(1) The differential level plug is located on the

lubricated.

right front of the axle housing. Remove plug and check

(2) Install output shaft in transmission.

level of oil. Oil should be to level of plug hole. Add

(3) Install drive shaft on transmission output

lubricant as required. Refer to current Lubrication Order

shaft and parking brake and secure with screws (2).

for correct lubricant. Install plug.

Tighten screws to a torque of 25 to 30 pound-feet (338

(2) The drain plug (Fig. 4-77) is located at the

to 40.6 N-m) dry or 20 to 24 pound-feet (27.1 to 32.5 N-

bottom of the differential housing. To drain axle,

m) lubricated.

remove level plug (Fig. 4-77).

Place a suitable

(4) Remove blocks and lower truck to ground.

container beneath axle, remove drain plug and drain

lubricant. Install drain plug and tighten securely. Refer

4-95.

Differential

to current Lubrication Order for correct lubricant and fill

housing through level plug hole. Install level plug.

a. General The differential provides a double

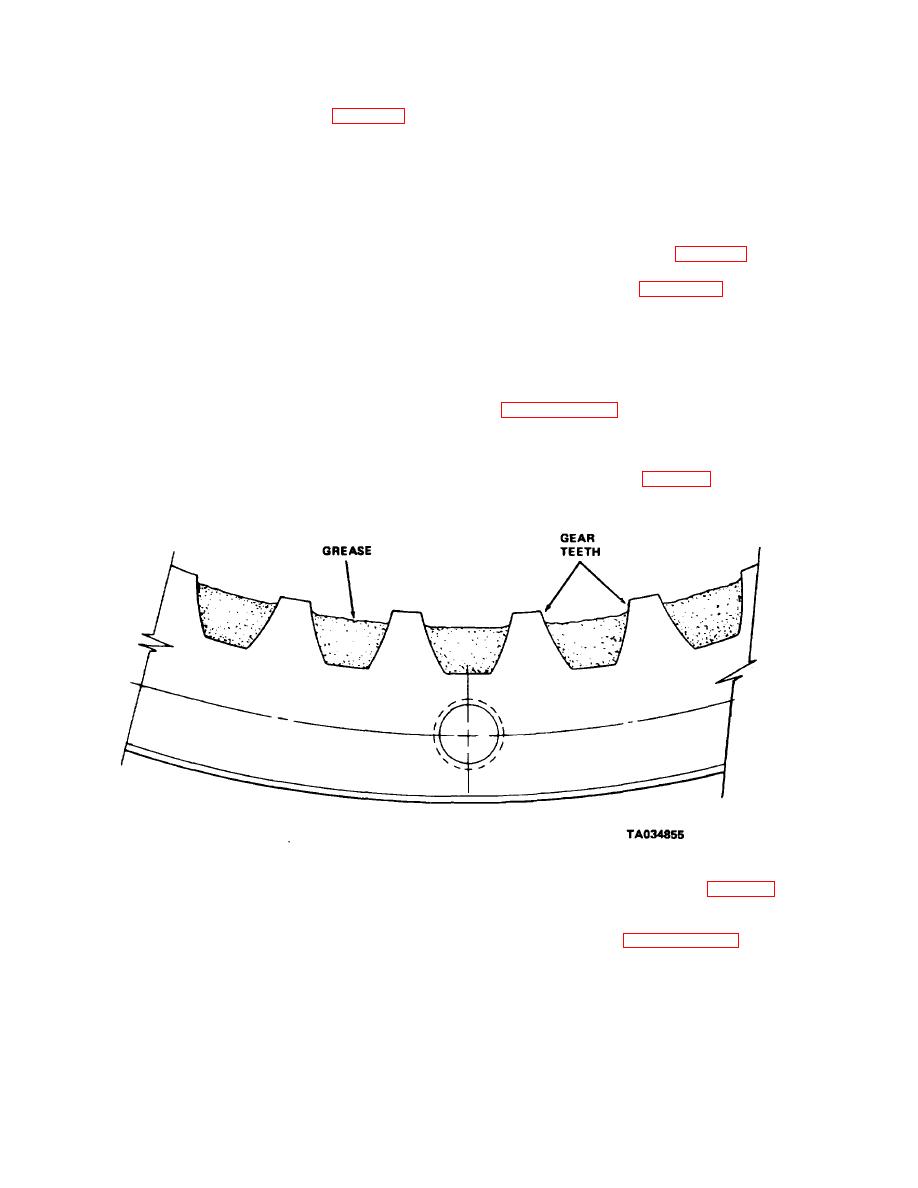

(3) Lubrication of axle pinion and ring or bull

gear is accomplished by removing the front wheel Refer

reduction internal gear drive. A pinion driven by the

to paragraph 4-85 and remove the front wheel Clean

drive shaft is meshed with a ring gear which drives the

pinion and ring gears with solvent and dry with

differential. The differential is splined to the axle shafts,

compressed air. Fill all spaces between ring or bull gear

which drive pinions that are meshed with the ring or bull

teeth with grease (GAA) to approximately three-fourths

gears in the wheels.

b. Service

the height of the teeth (Fig. 4-80). Refer to paragraph 4-

85 and install front wheels.

(1) Axle Breather. The breather is located on

the right top of the differential housing. Remove

Figure 4-80. Ring or bull gear lubrication.

4-96. Axle Shafts

cracked, broken, damaged or worn teeth.

(3) Inspect axle pinion (Fig. 4-71) for cracked,

a. General Drive from differential to the wheels is

broken, damaged or worn teeth.

provided by the axle shafts. The inner end is splined to

c. Removal

the differential and the outer end acts as a pinion riding

(1) Refer to paragraph 4-85 and remove front

in the ring or bull gear of the wheel.

wheels and dust shield.

b. Inspection

(2) Remove two screws and lockwashers

(1) Refer to paragraph 485 and remove the

secur

front wheels 440

(2) Inspect ring or bull gear in wheel for

4-88

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |