|

|||

|

|

|||

|

Page Title:

Transmission Linkage Adjustments |

|

||

| ||||||||||

|

|

7-6. Transmission Oil Pressure Checks

7-5. Transmission Linkage Adjustments

a. Checking the control pressures of the transmission

a. When transmission is shifted to neutral, groove pin

is an accurate and simple method of diagnosing the

on collar assembly (3, fig. 7-3) on shift lever (2) should

causes of specific or general malfunctions.

align with neutral indicator. Shift transmission to neutral

and check position.

b. If position needs adjustment, remove floorboards.

points shown with an accurate pressure gage. Compare

pressure readings obtained with situations covered in

Adjust position of lever by lengthening or shortening

directional rod (6) by adjusting position of ball joints on

transmission.

rod. Tighten lock nuts to secure adjustment. Check

positions of shift lever in relation to shift positions of the

transmission.

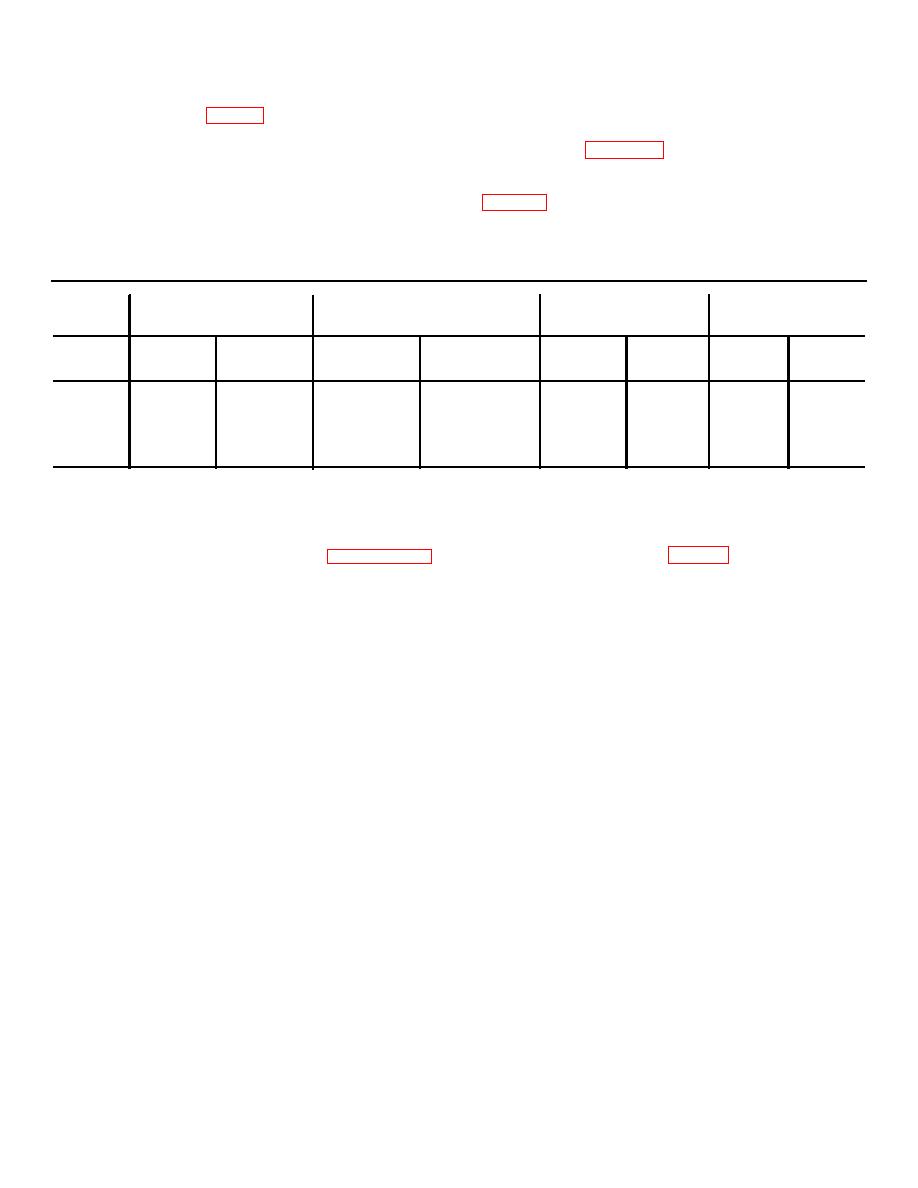

Table 7-1. Transmission Pressures

Engine

Converter charging

Forward

Reverse

RPM

Main line

pressure

clutch

clutch

Minimum

Maximum

Minimum

Maximum

Minimum

Maximum Minimum

Maximum

500

20

30

15

25

15

25

15

25

1000

58

68

42

50

50

58

50

58

1500

110

120

4

84

77

87

77

87

2000

120

135

84

101

80

93

80

93

All speeds: With inching valve out to stop, pressure to clutches is "O"

on a wheeled dolly so it may be drawn from truck when

7-7. Transmission Removal

ready.

a. Drain cooling system, transmission and axle.

Remove power axle as explained in paragraph 2-8,

and carefully draw transmission straight off engine until

supporting transmission against falling as axle is

input shaft splines are free of torque converter (13)

removed.

bore. Torque converter will remain on engine flywheel,

b. Disconnect cooling hoses neutral safety switch

and may be left there if it is not to be replaced.

leads, and all linkage at transmission. Support front of

engine by blocking and support transmission now

7-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |