|

|||

|

|

|||

|

Page Title:

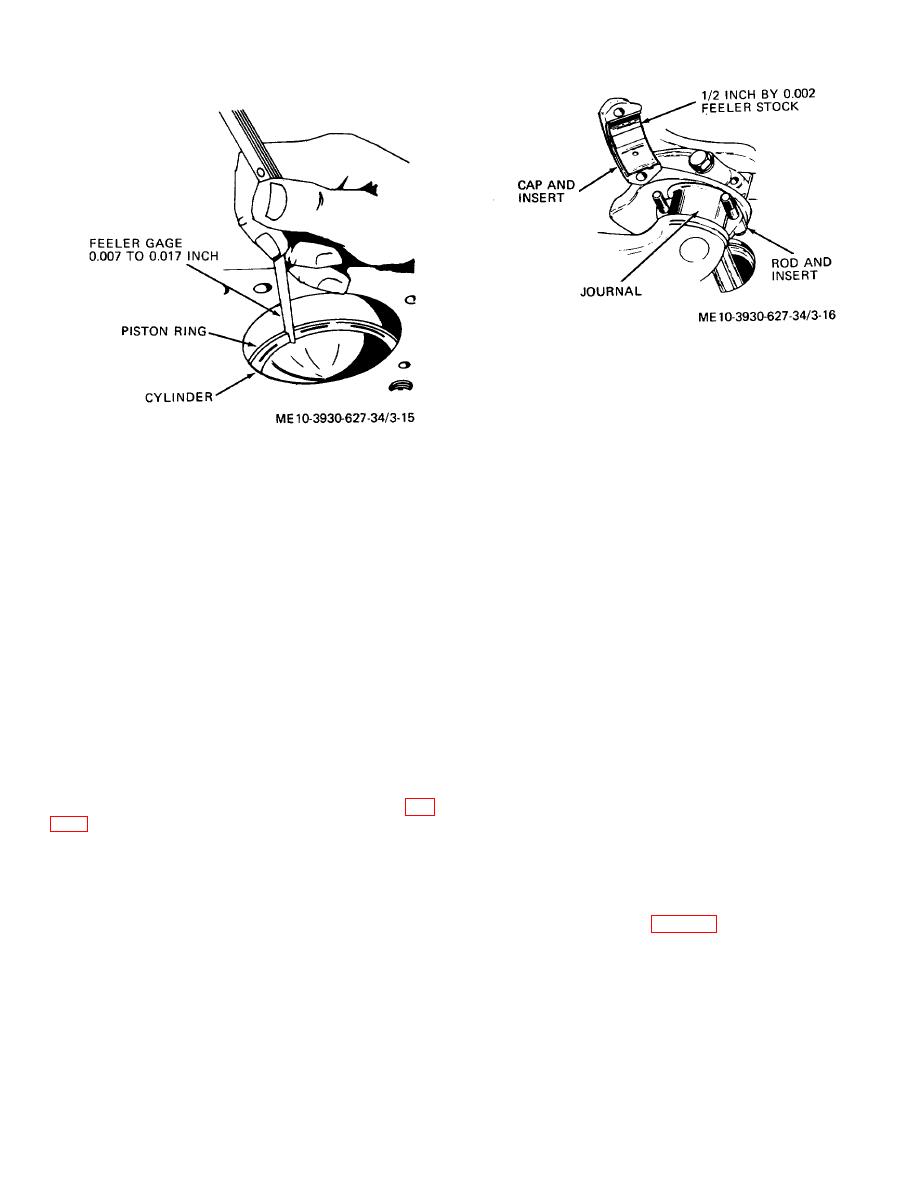

Figure 3-15. Measuring piston ring end gap. |

|

||

| ||||||||||

|

|

Figure 3-16. Checking connecting rod bearings.

i. Installation.

(1) It is important to remove glaze on cylinder

bore to assure quick seating of piston rings.

(a) Cover crankshaft journals with clean cloth

to prevent dirt and abrasives from getting on crankshaft.

Figure 3-15. Measuring piston ring end gap.

(b) Surface hone cylinder bores with glaze

breaker to break glaze and produce dull finish in bore.

g. Connecting Rod Alignment.

Clean glaze breaker between use in each cylinder bore

(1) Install piston pin in connecting rod and place

to reduce amount of loose abrasives released in bore.

connecting rod on aligning fixture. Install connecting rod

(d) Clean cylinder bores thoroughly with clean

bearing cap on connecting rod.

oiled rag to pick up any abrasive that might be left in

(2) Pin should touch measuring bar on aligning

bore. Follow this with clean cloth to assure that walls

fixture at both ends. Straighten slightly bent or twisted

are clean.

connecting rods. Maximum bend or twist may not

(2) Install oil rings and compression rings on

exceed 0.002 inch over 4 inch spread of length of the

piston with ring expander tool. Start with lowest ring

connecting rod.

first. Make sure that tapered side of compression ring

h. Connecting Rod Bearing Installation.

(look for work "TOP" on surface) is up. Make sure that

(1) Connecting rod bearings that are scored,

the ring gaps are equally spaced about circumference of

burned, or worn must be replaced by new ones.

the piston, not in vertical alignment.

Replacement bearings require no reaming or fitting.

(3) Oil cylinder wall and generously coat piston

(2) Install the piston with connecting rod and with

and rings with engine oil to insure initial lubrication when

upper half of connecting rod bearing installed, but

engine is first started after repair work.

without piston rings, in the cylinder bore. Coat a piece

(4) Install ring compressor on piston and

of 0.002 inch feeler stock, approximately 1/2 inch wide

compress rings into grooves. Tap compressor lightly

and 1 inch long, with oil and place it between the lower

around circumference of piston to allow rings to seat

connecting rod bearing half and crankshaft journal (fig.

evenly in grooves.

(5) Put a light coat of oil in the crankshaft end of

nuts to 35 to 40 foot-pounds torque. Try to rotate

the connecting rod and install upper half of connecting

crankshaft one full turn by hand. If slight consistent

rod bearing, making certain that the bearing lock fits in

drag is felt, the clearance is correct. If the crankshaft

the machined groove in the rod. Apply a light coat of oil

turns freely, it will be necessary to measure crankshaft

to the bearing half and install the piston and connecting

journal for taper or out-of-round. If taper or out-of-round

rod in the cylinder bore (fig. 3-17). Be very careful not

exceeds 0.001 inch, replace crankshaft, or grind to next

to damage the cylinder bore with the connecting rod big

standard undersize, and use corresponding undersize

end when installing pistons.

bearings.

3-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |