|

|||

|

|

|||

|

Page Title:

Section V. PREVENTIVE MAINTENANCE CHECKS AND SERVICES |

|

||

| ||||||||||

|

|

Section V. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

inspection requirements.

All deficiencies and

4-11. General

shortcomings will be recorded, together with the

a. To ensure that the forklift truck is ready for

corrective action taken, on DA Form 2404, (Equipment

operation at all times, it must be inspected

Inspection and Maintenance Worksheet) at the earliest

systematically, so that defects may be discovered and

possible opportunity.

corrected before they result in serious damage or failure.

b. A quarterly interval is equal to three calendar

The necessary Preventive Maintenance Services to be

months or 250 hours of operation, whichever occurs first.

performed are listed and described in table 4-1. The

item numbers indicate the sequence of minimum

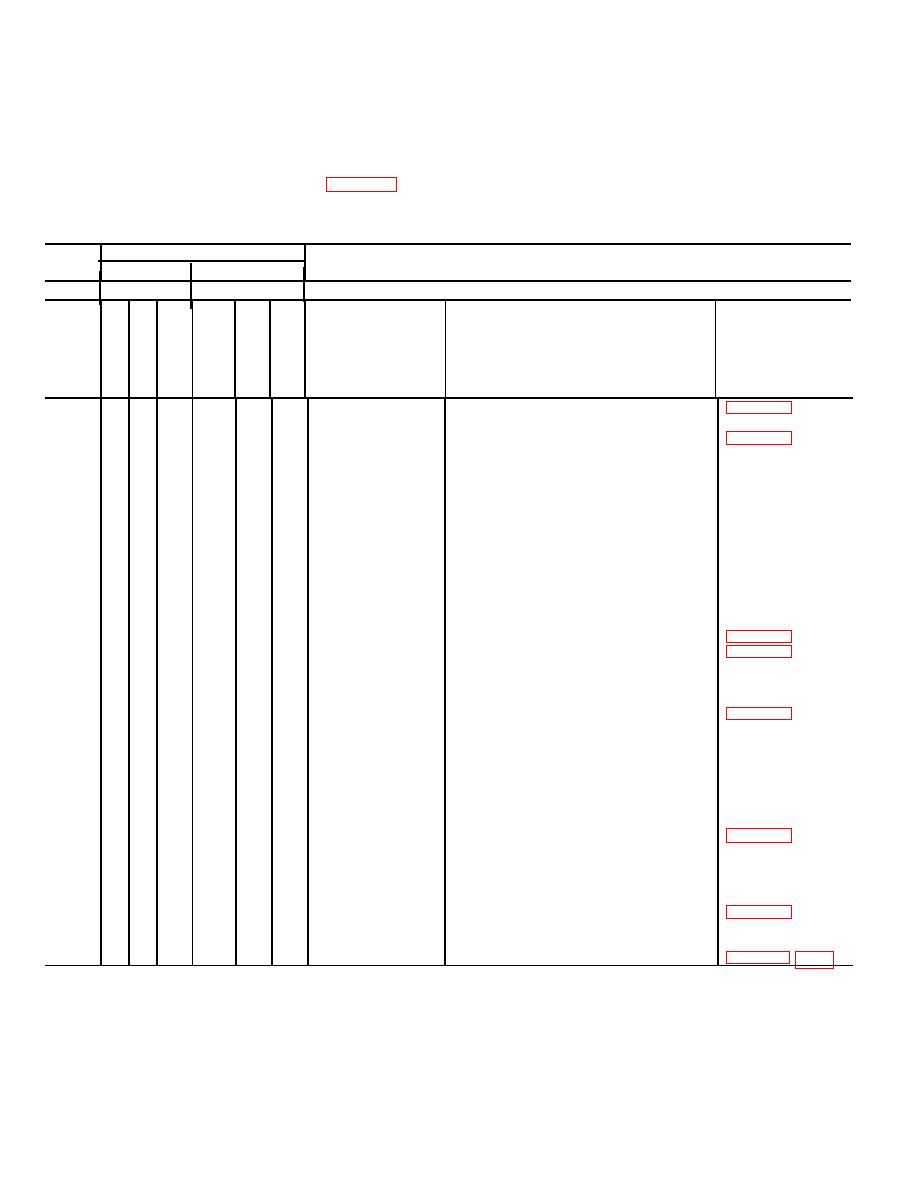

Table 4-1 Preventive Maintenance Checks and Services

Interval

B-Before operation

-After operation

M-Monthly

Operator

Org

D-During operation

-Weekly

Q-Quarterly

DAILY

I

N

T

U

E

M

M

B

W

M

Q

ITEM TO BE

PROCEDURE

REFERENCE

E

INSPECTED

R

B

D

A

Check operation. Replace defective lamp

Lights

X

X

1

or lamp unit.

Check for cracked, broken, or excessive

Lift Chain

X

X

2

worn links. If any such defects are found

replace both chains.

Refer maintenance

Check for leaks.

Lift Cylinder

X

X

3

to direct and

general support

personnel.

Inspect for broken seal. Check extin-

Fire Extinguisher

X

X

4

guisher for minimum allowable weight and

pressure.

Refer to direct

Check for cuts. Remove foreign material.

Tires

X

X

5

support personnel

for replacement.

Check for leaks or damage.

Tilt Cylinder

X

X

6

Check for strong pressure when brake

Brake Pedal

X

X

7

pedal is applied. Check travel. Adjust if

necessary. Pressure should increase

after 3/8 to 5/8 inch travel.

Check master cylinder and lines for leaks

Master Cylinder

X

X

8

and loose connections. Fill to within

inch of top. Tighten loose connections.

Replace leaking master cylinder.

Refer maintenance

Check for defects.

Pump Motor

X

X

9

to direct and

Brushes

general support

personnel.

Remove corrosion. Add fluid as needed.

Battery

X

10

Check fluid level.. Add fluid as needed.

Fill to cover bottom

Replace a dirty or damaged breather cap

Hydraulic Oil

X

X

11

of strainer with

strainer. Clean or replace a dirty or

Reservoir

mast down.

damaged filter screen (Q).

Check for loose mounting and damage.

Controls and In-

X

X

12

With unit operating, check for proper

struments

operation.

Check operation. Replace defective horn.

Horn

X

X

13

Note. During operation observe for any unusual noise or vibration.

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |