|

|||

|

|

|||

|

Page Title:

Figure 4-18. Pivot arm bearings. |

|

||

| ||||||||||

|

|

tightness of ball studs and pins in pivot arms.

Inspect all the bearings, tie rods parts, ball studs,

and ail other parts for damage or excessive wear.

(3) Replace any parts which show excessive

wear or damage.

d. Reassembly. Reassemble the components in

reverse o r d e r o f d i s a s s e m b l y o b s e r v i n g t h e

following :

(1) Hand pack the king pin needle bearings

(39, fig. 4-17) with wheel bearing grease, and

grease the thrust washers (38). Position each

spindle (36 and 37) and thrust washer in the steer

axle (40). Position the king pin (33) with the slot

toward the top. Make sure the roll pin hole in the

spindle will lineup with the roll pin hole in the king

pin.

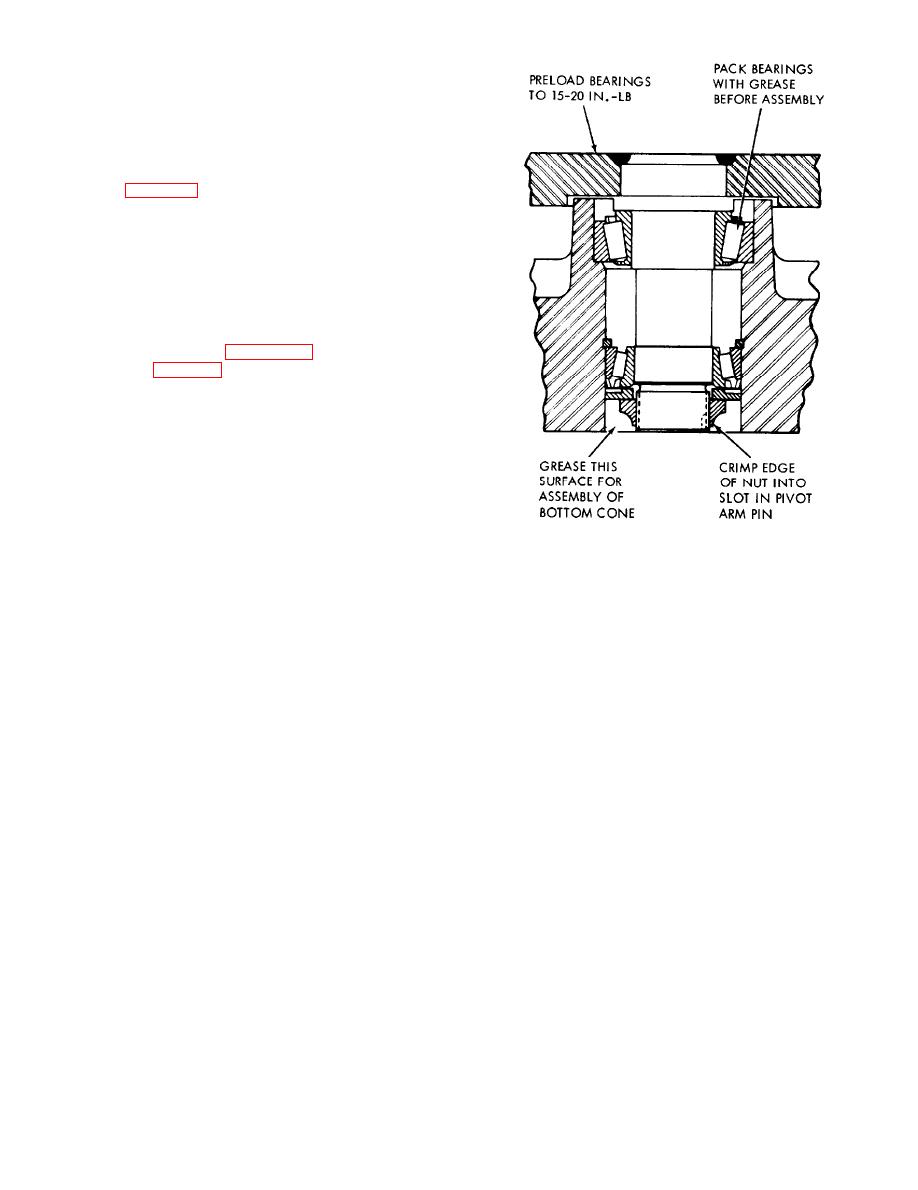

(2) Hand pack the pivot arm bearings (27 and

30) with wheel bearing grease, and press them into

the steer axle. See figure 4-18. Position the pivot

arm (25, fig. 4-171, pivot arm bearings and bearing

cups (27 and 30), lock ring (28), washer (24), and

retaining nut (23) in the steer axle. Pre-load the

pivot arm bearings to 15-20 in. lbs. Crimp the

edge of the retaining nut (23) into the slot in the

pivot arm pin.

ME 3930-624-34/4-18

Figure 4-18. Pivot arm bearings.

4-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |