|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

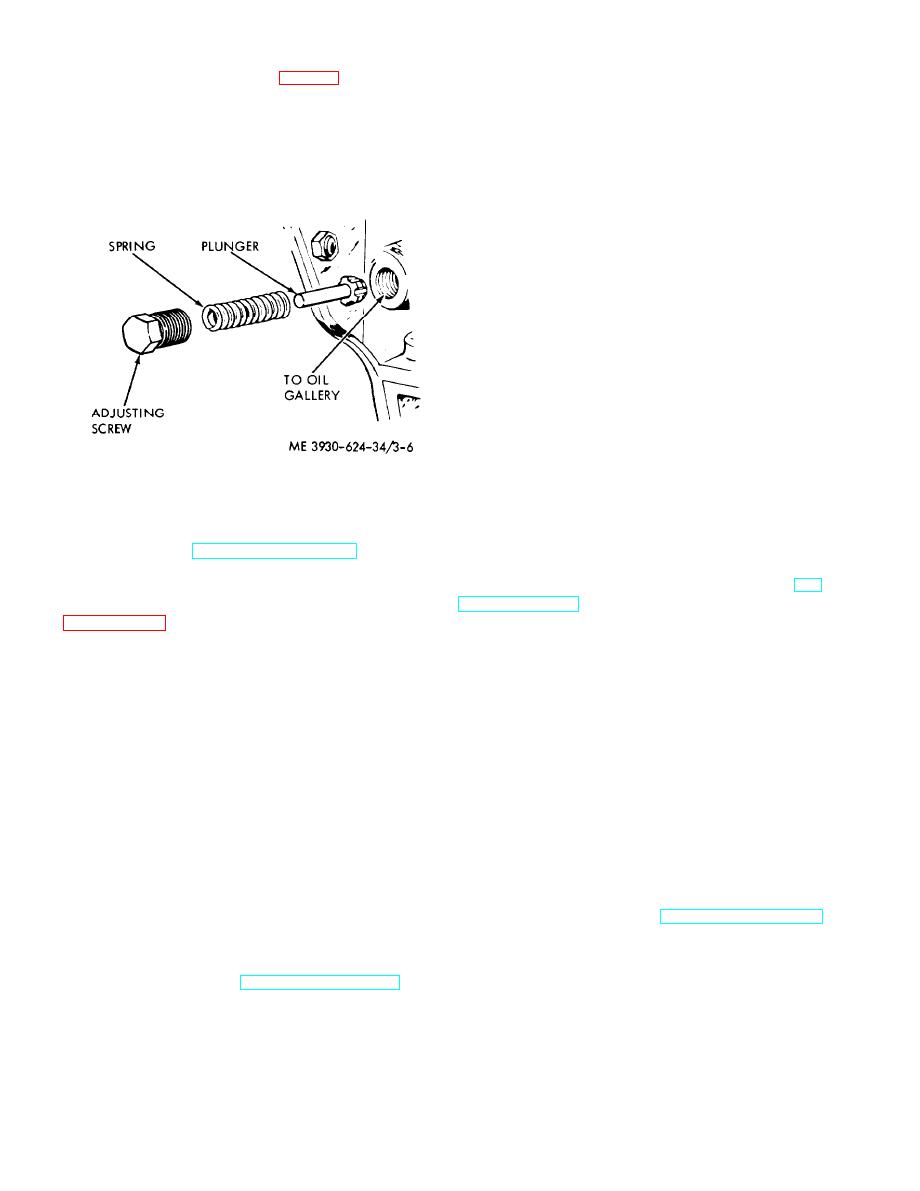

3-7. Oil Pressure Valve Adjustment

Note. It will be necessary to work through the coun-

terweight in order to remove the front oiI pan capscrews.

a. Start the engine and operate at half throttle.

Observe the engine oil pressure gage.

(4) Remove the rapscrews from the front and

side of the oil pan, and remove the oil pan.

gage reading of approximately 10 psi.

b. Installation.

c. Allow the engine to reach operating tem-

(1) Cement a new gasket to the oil pan side

perature and operate at high idle. Turn the ad-

rails.

justing screw if necessary to obtain a gage reading

(2) The oil seal at the rear of the engine

of 25 to 30 psi.

should be replaced when the engine is overhauled.

If the engine has not been overhauled. inspect the

lower portion of the seal to make certain it is in

good condition. If the seal has to be replaced, it will

be necessary to remove the flywheel housing.

(3) When the engine is overhauled. the oil pan

front gasket should be cemented to the rear of the

front plate before it is secured to the front of the

c y l i n d e r b l o c k . I f t h e engine has not been

overhauled and the oil pan portion of the gasket is

dam aged, scrape away the gasket as far as the

cylinder block rails. Cut the lower portion from the

new gasket and cement it in position on the front

plate assembly.

(4) Before installing the oil pan, place a small

quantity of a nonhardening sealing compound in

the corners formed by the flywheel housing and

cylinder block rails, and front plate assembly and

Figure 3-6. Oil pressure valve.

cylinder block rails. This will prevent oil leaks at

these points.

3-8. Oil Pan

(5) Position the oil pan on the cylinder block

a. Removal.

rails and secure with capscrews and lockwashers.

(1) Refer to TM 10-3930-624-12 and drain

Tighten the capscrews to a torque of 18 to 21 ft lbs.

the engine oil.

(6) Service the engine with oil. Refer to LO

(2) Remove the grille from the counterweight.

10-3930-624-12.

(3) Remove the steer axle assembly. Refer to

Section III. REPAIR OF THE COOLING SYSTEM

3-9. General

b. Testing.

(1) Completely drain the coolant from the

The cooling system cools the engine, torque con-

radiator before testing.

verter. and transmission. The system consists of the

(2) Plug all radiator outlets except the top

radiator. thermostat. fan. water pump, and hoses.

outlet. Immerse the radiator in water and apply 10

The water pump circulates the coolant through the

psi air pressure through the top outlet.

engine and returns it to the radiator. The coolant is

(3) Carefully check for air bubbles which

then cooled by a flow of air drawn across the

indicate a leak.

radiator by the fan. When the engine coolant is

below operating temperature, the thermostat closes,

after soldering to prevent corrosion of the metal

preventing the circulation of coolant until it reaches

tubes.

the proper temperature. Torque converter and

d. Installation. Refer to TM 10-3930-624-12.

transmission oil is transferred through hoses to the

lower part of the radiator where it is cooled.

3-10. Radiator

a. Removal. Refer to TM 10-3930-624-12.

3-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |