|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(3) After assembling the pump, rotate the gear

lockwasher and tighten both capscrews to a torque

(8) to make sure it turns freely.

of 18 to 21 ft lbs. Do not overtighten the capscrews.

e. Installation.

(g) After the pump is secured in position,

(1) Use the following procedure to install the

check the gear backlash between the drive gear and

oil pump. If the distributor and the oil pump were

the gear on the camshaft. Correct gear backlash is

both removed from the engine, refer to (2), below.

0.004-0.010 inch and can be checked through the

(a) Make certain the distributor rotor is

opening at the fuel pump mounting pad.

aligned with the reference mark made on the side of

(h) Install the oil tube from the block to the

the distributor housing as instructed in a, above.

pump and tighten the nuts securely.

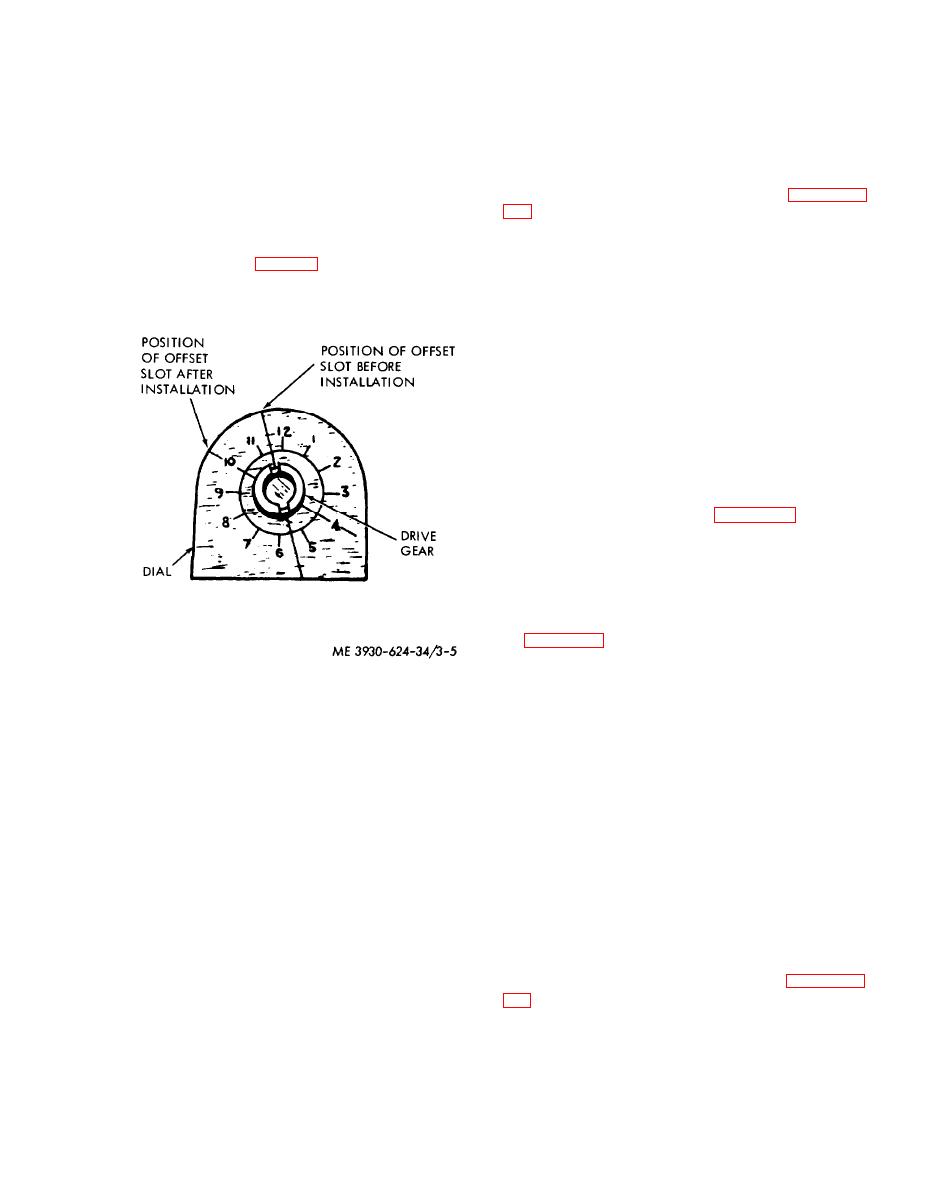

(b) Position the offset of the oil pump in the

cylinder block. Use a dial indicator to position the

offset of the pump drive gear to the right, towards

(2) If the engine was overhauled, or if the oil

the rear of the cylinder block, so the slot will be at

pump and the distributor were both removed, use

the specified angle (fig. 3-5).

the following procedures to install the oil pump.

(a) Rotate the crankshaft in the direction of

engine rotation until the No. 1 cylinder exhaust

valve lobe on the camshaft points horizontally to

the side of the cylinder block. When the No. 1

cylinder exhaust valve camshaft lobe is in this

position, the piston is on the compression stroke

near or at top dead center. The timing mark

stamped on the flywheel should be in the timing

hole in the flywheel housing.

(b) Position the offset of the oil pump in the

cylinder block. Use a dial indicator to position the

offset of the pump drive gear to the right towards

the rear of the cylinder block, so the slot will be at

the specified angle. Refer to figure 3-5.

(c) Insert the oil pump in the cylinder block,

engaging the oil pump drive gear with the gear on

the camshaft. As the pump drive gear meshes with

the camshaft gear, it will rotate slightly. When the

pump gear is fully engaged with the camshaft gear.

the slot will be positioned at a specified angle. Refer

to figure 3-5. Install the capscrews finger-tight to

hold the pump in position.

(d) Insert the distributor into the cylinder

block and rotate the rotor until the offset tang on

Figure 3-5. Positioning drive gear offset slot.

the distributor drive engages the slot in the pump

drive gear. In this position the rotor will be pointing

(c) Insert the oil pump in the cylinder block,

to the No. 1 cylinder spark plug wire in the

engaging the oil pump drive gear with the gear on

distributor cap.

the camshaft. Install one retaining capscrew and

(e) Install the cap on the distributor.

lockwasher and tighten only enough to hold the

(f) Install the second retaining capscrew

pump in place.

and lockwasher and tighten both capscrews to a

Caution: Do not tighten the capscrews

torque of 18 to 21 ft-lbs. Do not overtighten.

unless the pump drive gear has properly

(g) After the pump is secured in position,

engaged with the gear on the camshaft and the

check the gear backlash between the drive gear and

tang on the distributor drive engages with the

the gear on the camshaft. Gear backlash is 0.004-

drive slot in the pump gear.

0.010 inch and can be checked through the opening

(d) After the oil pump is in mesh with the

at the fuel pump mounting pad.

gear on the camshaft, check to make certain that

(h) Install the oil tube and tighten the front

the distributor drive has engaged the slot in the

and rear tube nuts securely.

pump drive gear. Make certain the rotor is pointing

to the reference mark made on the side of the

housing.

(e) Install the cap on the distributor.

(f) Install a second retaining capscrew and

3-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |