|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

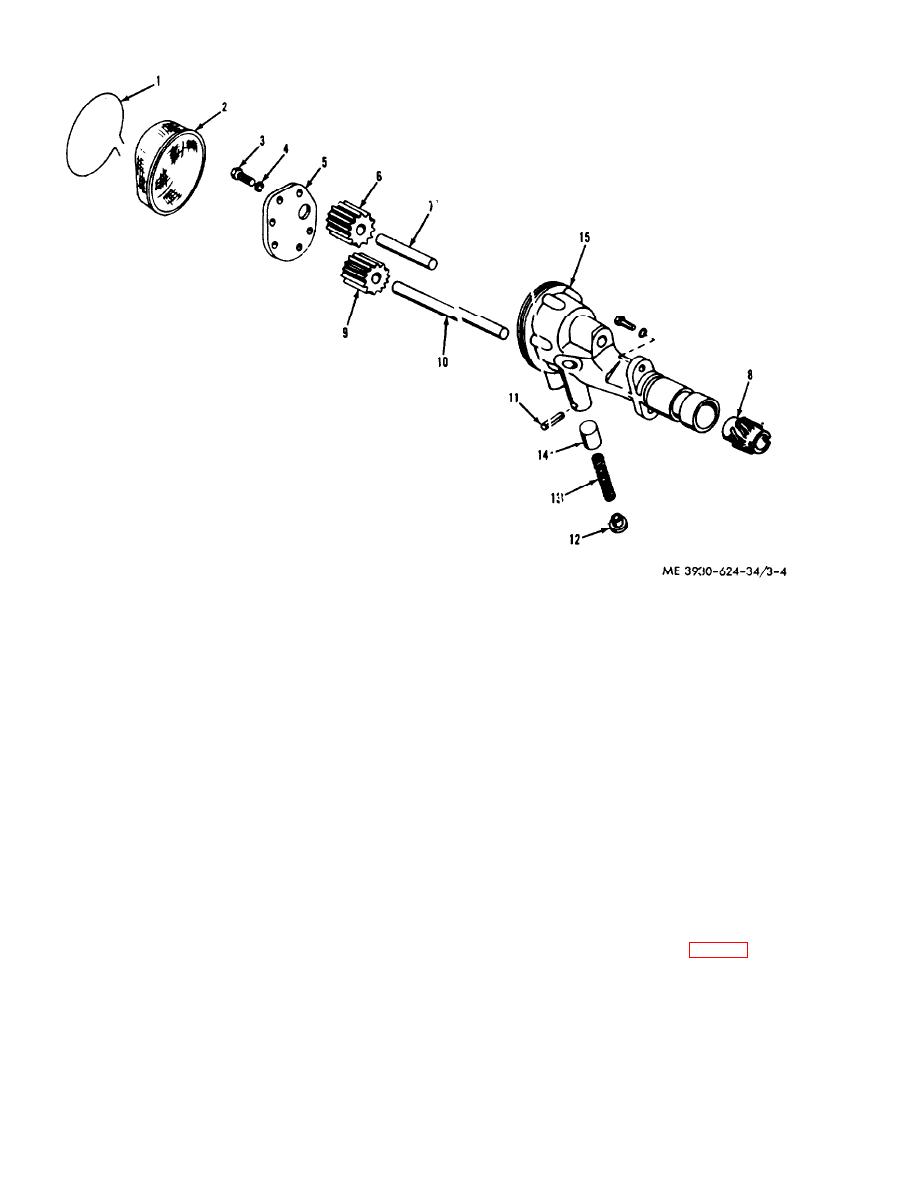

11. Pin

6. Idler gear

1. Wire

2. Screen

7. Idler shaft

12. Retainer

13. Spring

8. Gear

3. Capscrew

4. Lockwasher

9. Drive gear

14. Piston

5. Cover

10. Drive shaft

15. Body

Figure 3-4. Oil pump, exploded view.

(2) Remove the idler gear (6) and the idler

(4) Install the gears and shafts in the pump

shaft (7).

body. Radial clearance between the gears and

(3) Place the pump in a press and remove the

pump body should be 0.001 to 0.002 inch. End

gear (8). Place a drift on the drive shaft and remove

clearance between the gears and pump cover should

the drive gear (9) and drive shaft (10).

be 0.002 to 0.004 inch and must not exceed 0.006

inch. Backlash between the pump gears should not

(4) Remove the pin (11). retainer (12), spring

exceed 0.020 inch. Replace parts as required.

(13) and piston (14).

Replace the pump if clearances are not maintained.

c. Cleaning and Inspection.

d. Reassembly. Assemble the oil pump in the

(1) Clean in a suitable solvent and dry with

reverse order of disassembly. Observe the

compressed air.

following :

(2) Inspect the gear teeth, inside of pump

housing and inner face of the cover for scratches,

(1) Press the gears (6 and 9, fig. 3-4) onto the

shafts (7 and 10) so that the gears are flush with the

cracks. nicks, burrs. scoring and other surface

damage. Smooth surfaces with a soft hone or crocus

ends of the shafts.

cloth or replace as required.

(2) Lubricate the shafts (7 and 10) before

(3) Inspect the pump shafts and shaft bores for

installing in the body.

scoring and wear.

3-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |