|

|||

|

|

|||

|

Page Title:

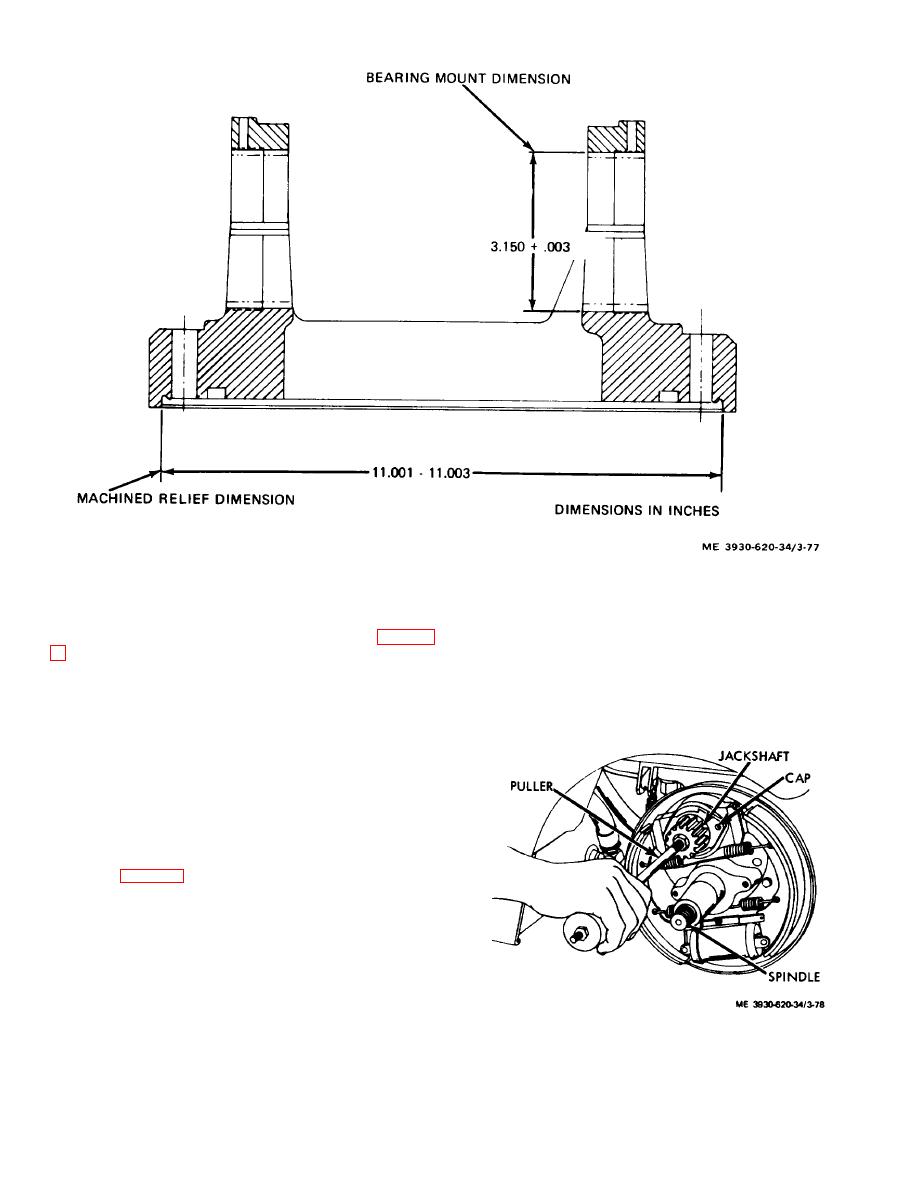

Figure 3-77. Differential carrier dimensions. |

|

||

| ||||||||||

|

|

Figure 3-77. Differential carrier dimensions.

(17) Remove inner oil seal from drive unit

3-44. Jackshaft

housing.

a. Removal, Cleaning, and Inspection.

(18) Clean and inspect all parts.

(1) battery and discharge capacitors (para 2-

Note.

Whenever jackshaft is

(2) Install wheel chocks forward and aft or

removed. oil seals shall be shall be

rear wheels to prevent lift truck from moving.

replaced.

(3) Using a suitable lifting device, raise front

(19) Replace oil seals and damaged or worn

end of lift truck above the ground, as required.

parts.

(4) Install blocking and remove lifting device.

(5) Remove drive wheel assembly (TM 10-

3930-(620- 12).

(6) Remove screws securing dust shield.

(7) Remove dust shield.

(8) Remove screws securing axle shaft cap.

(9) Remove axle shaft cap.

(10) Install puller in threaded hole in end of

jackshaft. (fig. 3-78.)

(11) Carefully remove jackshaft and bearing

assembly as a unit.

(12) Straighten prongs of lock washer.

(13) Remove lock nut, lock washer, and

washer.

(14) Place jackshaft assembly in suitable

press.

Caution: Use care to prevent

Figure 3-78. Jackshaft removal.

damaging axle shaft cap.

b. Installation.

Wheel bearings and jackshaft

(15) Remote bearings and bearing cap.

bearings shall not be lubricated with grease containing

(16) Slide retainer cap off jackshaft

molybdenum-disulfide which is also known

3-90

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |