|

|||

|

|

|||

|

Page Title:

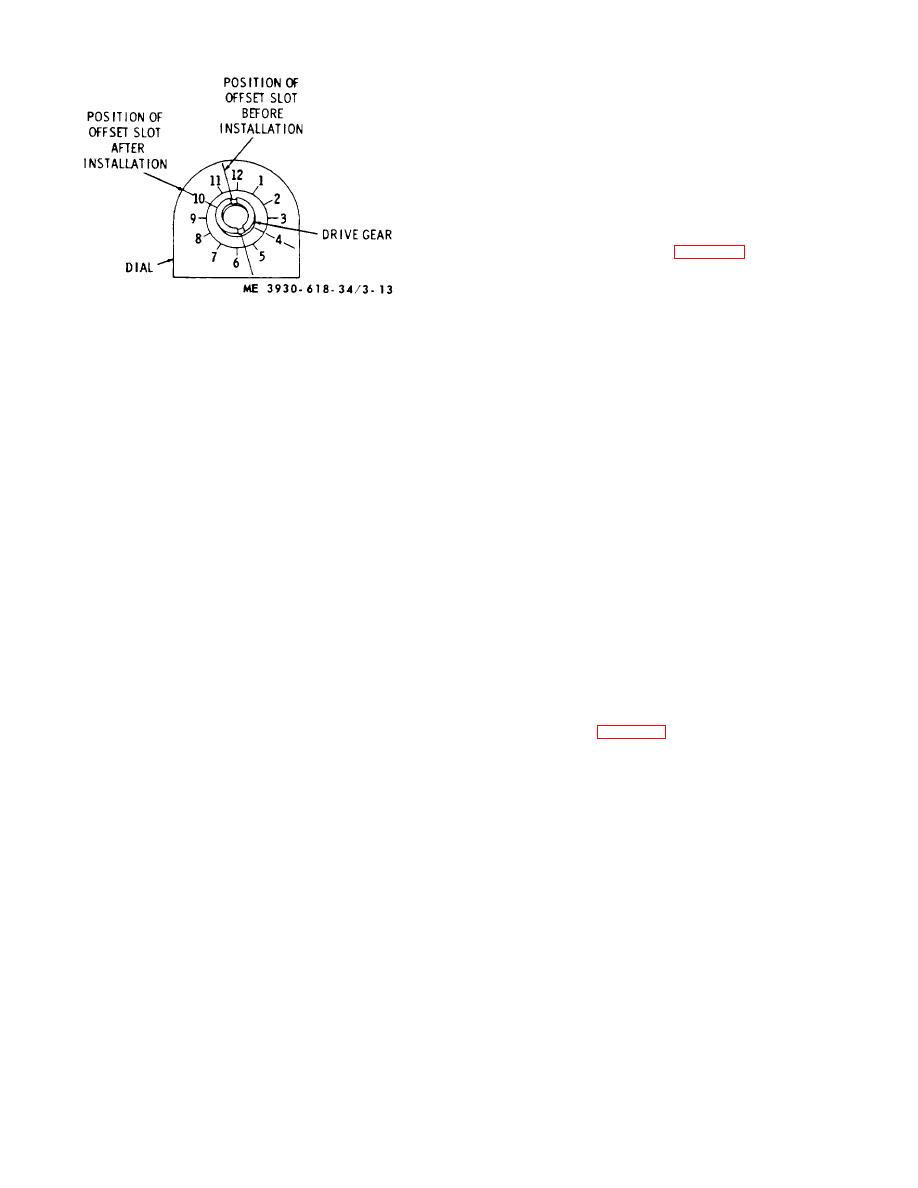

Figure 3-13. Positioning drive gear offset slot. |

|

||

| ||||||||||

|

|

flange and screw nut into flange to a point where tube

can still be turned.

(c) Cement a new gasket on flange.

(9) Position assembled flange, relief valve,

and tube b, inserting rear end of tube in cylinder block at

No. 6 main bearing cap and placing flange against oil

pump with relief valve down.

(10)

Start rear tube nut and tighten

securely. Install and tighten the two flanges to oil pump

retaining capscrews and lockwashers. Torque to 11-13

ft.-lbs. Securely tighten front tube nut.

(11) Install oil pan (para 3-12).

g. Installation After Engine Overhaul.

During

engine overhaul, distributor and oil pump are removed

from cylinder block. In order to mesh oil pump drive gear

with gear on camshaft in original factory location, so rotor

Figure 3-13. Positioning drive gear offset slot.

in distributor will point to No. 1 cylinder spark plug wire,

proceed as follows:

(3) Insert oil pump in cylinder block with drive

(1) Rotate crankshaft in direction of engine

gear positioned as indicated in (2) above and mesh it

rotation until No. 1 cylinder exhaust valve lobe on

with gear on camshaft. Install one oil pump retaining

camshaft points horizontally to side of cylinder block.

capscrew and lockwasher and tighten only enough to

Whenever No. 1 cylinder exhaust valve camshaft lobe is

hold pump in place.

in this position, piston is on compression stroke near or

CAUTION

at top dead center and timing mark stamped on flywheel

It is possible oil pump drive gear

should be in timing hole in flywheel housing.

engaged gear on camshaft one tooth

one way or the other from correct

NOTE

position and tang on distributor drive

Number 1 cylinder exhaust valve

did not engage drive slot in pump

camshaft lobe is first lobe from front of

gear; therefore, if pump retaining

engine.

capscrews are tightened securely at

this time, undue strain will be placed

(2) Position offset slot of oil pump drive gear.

on distributor and advance arm

Refer to f (2) above.

assembly.

(3) Insert oil pump in cylinder block with drive

(4) After oil pump is in mesh with gear on

gear position as indicated in f (2) above and mesh it with

camshaft, check to make certain distributor drive has

gear on camshaft. Note that as pump drive gear meshes

engaged slot in pump drive gear and rotor is pointing to

with camshaft gear, it will rotate slightly because gears

reference mark made on side of distributor housing.

are helical type. When pump gear is fully engaged with

(5) Install cap on distributor.

cam gear, slot will be positioned at an angle of 4: 00 -

CAUTION

10: 00-o'clock (fig. 3-13). This is correct position for

Overtightening may break mounting

slot in pump drive gear to drive distributor. Install

flange. Note that flange is not flush

capscrew finger tight to hold pump in position.

(4) Insert distributor into cylinder block and

with cylinder block.

rotate until offset tang on distributor drive engages slot in

(6) Install second pump retaining capscrew

pump drive gear. In this position rotor will be pointing to

and lockwasher and tighten both capscrews to 1821 ft.-

No. 1 cylinder spark plug wire in distributor cap.

lbs. torque.

(5) Complete installation of oil pump as

(7) After pump is secured in position, check

outlined in f above.

gear backlash between pump drive gear and gear on

camshaft. Gear backlash is 0.004-inch -0.010inch, and

3-14. Oil Pressure Relief Valve

can be checked through opening at fuel pump mounting

a. Description.

Stabilized oil pressure is

pad.

maintained in engine lubrication system by an adjustable

(8) Assemble oil relief valve mounting flange,

oil pressure regulating valve located in main oil gallery at

relief valve, and oil tube assembly as follows:

front left corner of cylinder block. This valve is factory

(a) Place lockwasher on relief valve and

set to open at 35 to 40 psi. When oil pressure at relief

screw it into flange. Torque valve to 40-50 ft.-lbs. and

valve exceeds its regulated pressure setting, plunger

lock in position by bending one tab against relief valve

opens and excess oil bypasses through lower drilled

and a second tab against flange.

capscrew.

(b) Position oil tube assembly (straight section) in

3-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |