|

|||

|

|

|||

|

Page Title:

Section V. REPAIR OF TORQUE CONVERTER AND PUMP |

|

||

| ||||||||||

|

|

The drilled capscrew secures camshaft thrust plate to

plunger and plunger spring in position in cylinder block.

front of cylinder block, and serves to lubricate gear train.

(2) Install pressure regulating valve adjusting

Pressure relief valve should require very little attention

screw and locknut. Make certain valve adjusting screw

under normal conditions. If engine lubricating system

is turned into cylinder block same number of turns

allowed to sludge, valve may not work properly. If

required for removal.

plunger binds in open position, a sharp drop in engine oil

(3) Start engine and operate at about one-half

pressure will occur; or, if plunger binds in closed position,

throttle. Observe engine oil pressure gauge, and adjust

a sharp rise in engine oil pressure will occur. If oil

oil pressure regulating valve to obtain a reading of

pressure should rise or drop sharply, relief valve must be

approximately 15-psi on gauge. After engine reaches

disassembled and checked for damage or sludge.

normal operating temperature. operate engine at high

Whenever oil pump or engine is disassembled. all

idle speed, adjust pressure regulating valve to obtain a

reading of 35-40 psi on oil pressure gauge, and tighten

components of oil pressure relief valve assembly should

locknut. No further adjustment of valve should be

also be removed, thoroughly cleaned, and inspected.

necessary.

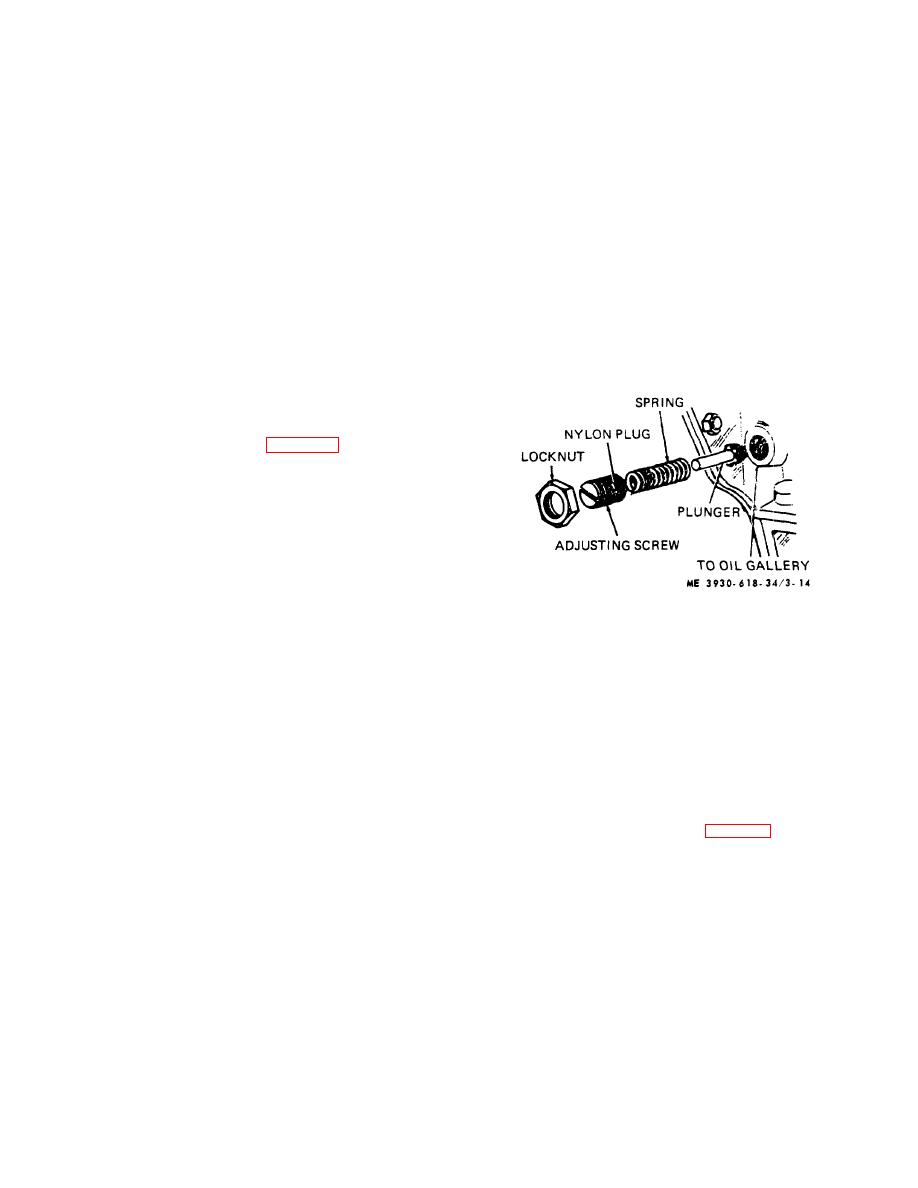

NOTE

(4) After engine has been run-in, oil pressure

A gasket between adjusting screw

operating range (with stabilized engine temperature)

locknut and cylinder block is not

is 25- to 35-psi at rated engine speed.

required because of nylon plug

located in side of adjusting screw

which prevents oil leakage past

threads.

b. Removal and Inspection.

(1) Loosen locknut (fig. 3-14) and remove

adjusting screw from cylinder block. While removing

adjusting screw, count number of turns required for

removal.

(2) Remove valve spring and plunger from

cylinder block.

(3) Wash all parts thoroughly in (Spec. P-

D680) and inspect. Replace any worn or damaged parts.

(4) Inspect valve seat in cylinder block and

clean if necessary.

c. Installation and Adjustment.

Figure 3-14. Oil pressure relief valve.

(1) Lubricate plunger with clean oil and install

Section V. REPAIR OF TORQUE CONVERTER AND PUMP

b. Test.

3-15. Torque Converter and Pump

(1) Pump pressure.

a. General. The "Power Shift" is dependent upon

(a)

To check pump pressure. install a

correct operating pressures for efficient operation. If in

pressure gauge calibrated to 300-psi, in the port marked

doubt, the pressures should be checked.

for the

"P" on the right side of the transmission. Leave the

following: Pump pressure, converter pressure, clutch

transmission in neutral and start the engine. Accelerate

pack pressure, and clutch cooling oil pressure.

the engine to full governed speed and note the pressure

NOTE

Oil temperature should be 80 to 100

indicated on the pressure gauge (fig. 3-15).

F, when checking pressure at idle

speed.

3-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |