|

|||

|

|

|||

|

Page Title:

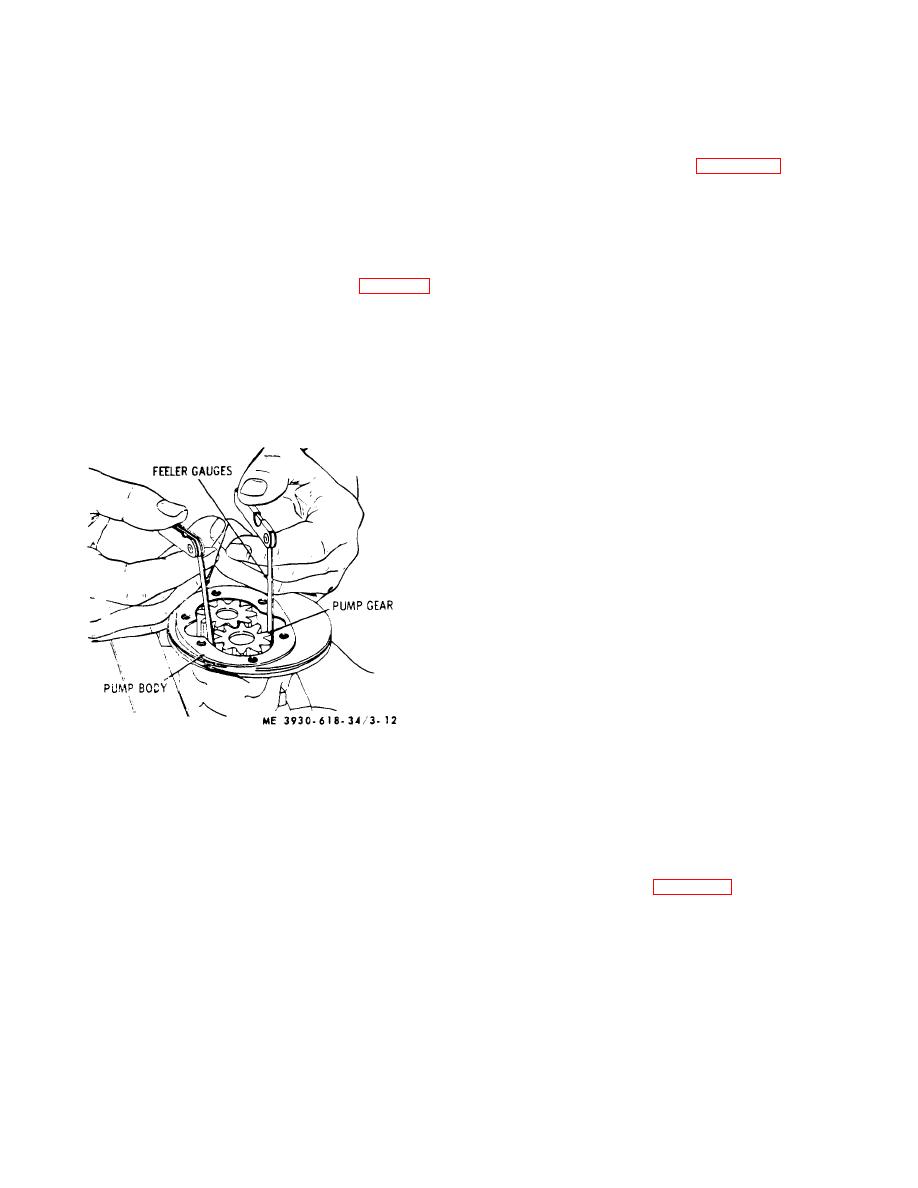

Figure 3-12. Checking oil pump radial clearance. |

|

||

| ||||||||||

|

|

from pump driving gear and pump body. d. Cleaning

0.004inch. Specified diameter of both pump drive shaft

and Inspection. If dirt and sludge are allowed to

and idler gear shaft is 0.4990-inch - 0.4995-inch. Pump

housing bore is 0.5005-inch - 0.5015 -inch; idler shaft

accumulate in engine lubricating system, oil pump wear

bore is 0.500-inch - 0.501-inch. If parts are worn or

may be rather pronounced in a comparatively short time.

damaged, replace pump.

When oil is kept clean and oil filter has been properly

(3) Thoroughly clean oil pump suction screen.

serviced wear on these parts should be very slight.

e. Assembly. Refer to figure 3-11 for relative

Wash all oil pump components in clean solvent, and

position of parts and assemble pump as follows:

thoroughly inspect and check parts as follows:

(1) When installing gears on idler shaft (14)

(1) Inspect pump gear teeth, inside of pump

or drive shaft (3), press shaft gear into gear until end is

body, and inner face of cover for wear and scoring. Gear

approximately flush with end of gear.

teeth, inside of pump body, and inner face of cover must

CAUTION

be smooth with no scratches, score marks, or rough

spots. Also, inspect pump shafts and shaft bores in

Shaft must not protrude past oil

pump body for excessive radial clearance (fig. 3-12)

pump cover end of gear.

between pump gears and pump body (0.001-inch to

(2) Lubricate pump drive shaft and insert (with

0.002-inch). End clearance (between pump gears and

drive gear in position) into bore in pump body.

pump cover) of gears in pump body is 0.002-inch - 0.

(3) Place pump body in position in a press,

004-inch, and must not exceed 0.006-inch. To check

supporting assembly on drive gear end of shaft. Place

clearance, lay pump cover across pump body. Insert a

pump driving gear in position! or: upper end of shaft,

feeler gage between pump cover plate and pump gears.

aligning pinhole in gear ,with hole in shaft. Press gear

Backlash between pump gears can be checked with a

onto shaft until pinhole in gear and shaft are aligned.

feeler gage and should not exceed 0.020-inch.

Install new roll pin.

(4) Lubricate idler gear shaft (4) and install

pump gears (15) and shaft in position in pump body.

Check dimension between gears and bottom face of

pump body. End clearance of gears should be 0.002-

inch - 0.004-inch.

(5) Place pump cover (9) in position on pump

body (4) and secure with the capscrews (11) and

lockwashers (10).

NOTE

No gasket is required between cover

and pump body.

(6) Place pump suction screen (12) in position

on bottom of pump body and secure with screen

retaining wire (13).

(7) After pump is completely assembled, it

must turn freely when rotating drive gear (1) by hand.

f. Installation.

The

following

installation

instructions apply when engine has not been

disassembled for complete overhaul or when oil pump

Figure 3-12. Checking oil pump radial clearance.

has been removed with engine in truck. For pump

installation instructions at engine overhaul. refer to g

(2) Inspect pump shafts for wear with a

below.

micrometer and pump body wear with a feeler gage.

(1) Make certain distributor rotor is aligned

Inspect for excessive wear or scoring and replace if

with reference mark made on side of distributor housing

necessary. Specified clearance between pump drive

as instructed in b (1) above.

shaft and pump housing bore is 0.0010-inch - 0.0025-

(2) Before installing oil pump in cylinder block,

inch and must not exceed 0.004 - 0.006-inch. Specified

use dial as illustrated in figure 3-13 to position offset of

clearance between idler gear shaft and pump housing

pump drive gear to the right and toward the rear of

bore is 0.0005 inch - 0.0029-inch, and must not exceed

cylinder block so that slot will be at an angle of 5: 30-to

11: 30-o'clock.

3-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |