|

|||

|

|

|||

|

Page Title:

Chapter 2. DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE |

|

||

| ||||||||||

|

|

CHAPTER 2

DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE

INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

direct and general support maintenance of the fork lift

2-1. Tools and Equipment

truck.

Tools, equipment, and repair parts issued with or

2-3. Maintenance Repair Parts

authorized for the fork lift truck are listed in TM 10-3930-

618-20.

Repair parts required to perform direct and general

support maintenance is listed and illustrated in TM 10-

2-2. Special Tools and Equipment

3930-618-34P.

No special tools or equipment are required to perform

Section II. TROUBLESHOOTING

Each malfunction stated is followed by a list of probable

2-4. General

causes of the trouble.

The corrective action

This section provides information useful in diagnosing

recommended is described opposite the probable cause.

and correcting unsatisfactory operation or failure of the

Refer to TM 10-3930-618-20 for initial troubleshooting

fork lift and its components.

information.

2-5. Troubleshooting

Malfunctions which may occur are listed in table 2-1.

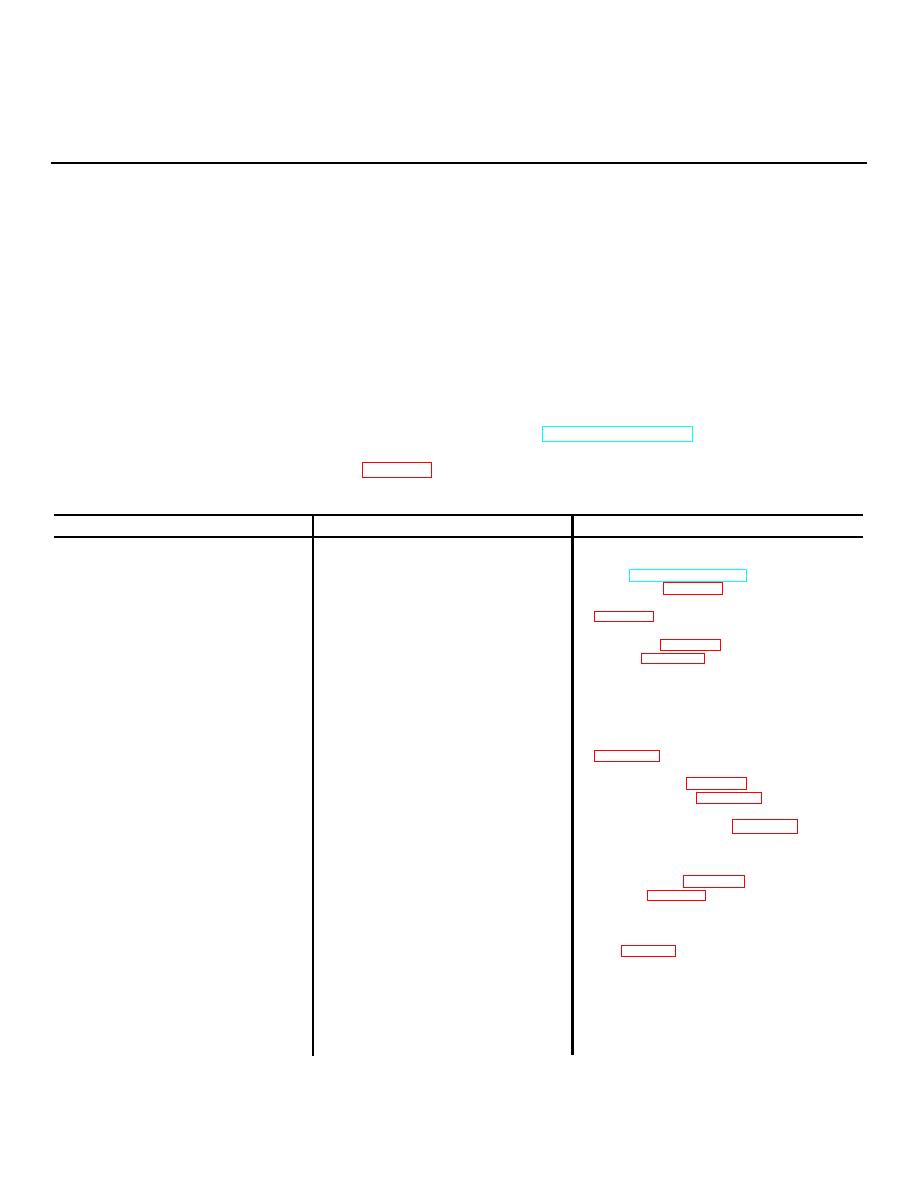

Table 2-1. Troubleshooting

Malfunction

Probable cause

Corrective action

1. Engine hard to start

No compression

Valves not seating properly. Either

adjust (TM 10-3930-618-20) or

grind valves (para 3-23).

a. Leaks at cylinder head gaskets

a. Tighten head or replace gasket

2. Engine misses

b. Engine overheats, causing valves

b. Free the valves by cleaning the

to stick

valve stems (para 3-23).

c. Warped valves

c. Replace (para 3-23).

d. Stuck valve

d. Remove valve cover and with

screwdriver, free the sticking

valve. Valve stem and guide will

have to be cleaned to restore

proper clearance. If condition

continues, valves need regrinding

3. Engine knocks

a. Carbon in combustion chamber

a. Remove cylinder head; scrape and

("piping" knock in cylinder)

clean out carbon (para 3-20).

b. Loose connecting rod bearing,

b. Replace bearings (para 3-22).

(Sharp knock, low oil pressure.)

c. Loose main bearing. (Heavy

c. Replace main bearings (para 3-21)

knock-low oil pressure.

d. Loose piston pins (Sharp double

d. Replace pins, or bushings (para

knock 3-22).

e. Piston and cylinder wear

e. Replace sleeve (para 3-20), piston

and rings (para 3-22).

4. Engine overheats

Leaky radiator.

Repair. Do not use quick-stop lead

solders, as these tend to clog the

circulation. Lead solder must be

used (para 3-6).

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |