|

|||

|

|

|||

|

Page Title:

CAMSHAFT, TAPPETS AND TIMING-GEARS |

|

||

| ||||||||||

|

|

ENGINE

required clearance, it should be removed and reground.

Crankshaft main bearing journals may be reground to

decrease the diameter a maximum of .040 inch.

Figure 41.

Figure 40.

9. Connecting rod bearings and crankpins may be

checked in the same manner with one exception;

instead of trying to turn the crankshaft when the

connecting rod bearing is tightened on it with a piece of

feeler gauge assembled, try to move the connecting rod

from side to side. When the connecting rod is perfectly

free, it will have from .006" to .010" side play and can be

moved by a light touch of the fingers. With feeler stock

assembled having a thickness equal to the maximum

Figure 42.

specified clearance, enough drag should be felt to

require pressure to move the rod from side to side.

shaft thrust plate to the front of the cylinder block, which

makes it possible to pull the camshaft forward out of the

CAMSHAFT, TAPPETS AND TIMING-GEARS

bearings. Unless engine is laying on its side, tappets

must be removed or lifted before camshaft can be

A. REMOVAL

pulled.

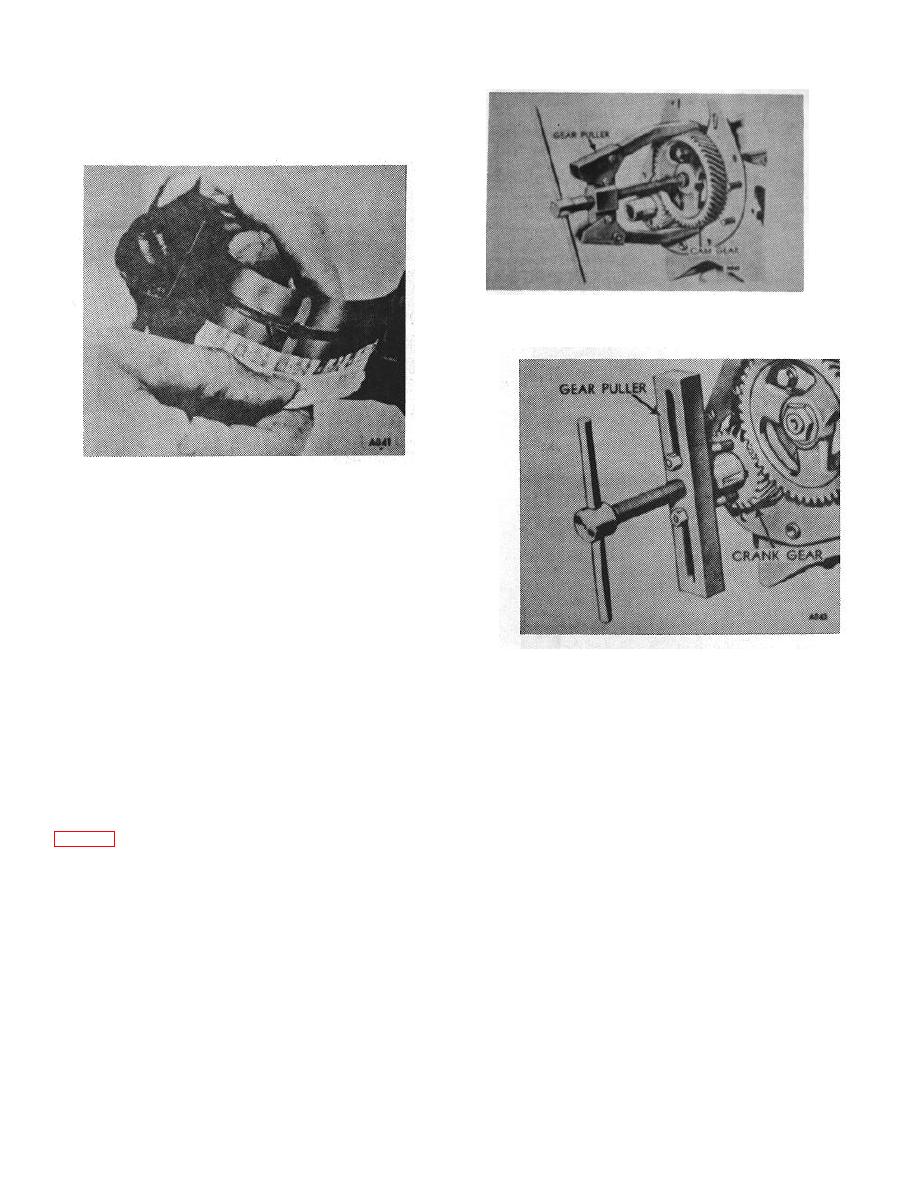

1. Remove valve cover. Then, using a puller,

3. Remove tappet cover. Tappets can then be

remove the cam and crank gears.

lifted out and lined up in sequence, for installation in the

same location, less inspection shows that they require

replacement.

2. Remove the screws holding the cam

4. Before pulling the camshaft completely, check

the clearance of the bearing journals in the bushing. To

do this, use strips of feeler stock 1/4" wide with edges

dressed with a stone to eliminate any burrs or feathered

edges.

B-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |