|

|||

|

|

|||

|

Page Title:

Bearing thickness wear must not exceed more than ,0005 inch. |

|

||

| ||||||||||

|

|

ENGINE

clearance permissible in the bearing lengthwise, in the

bearing shell, on a film of oil. (Fig. 39) Assemble the

bearing cap and tighten the screws, torquing them to

specifications. Try to turn the crankshaft by hand to

determine whether or not there is any drag.

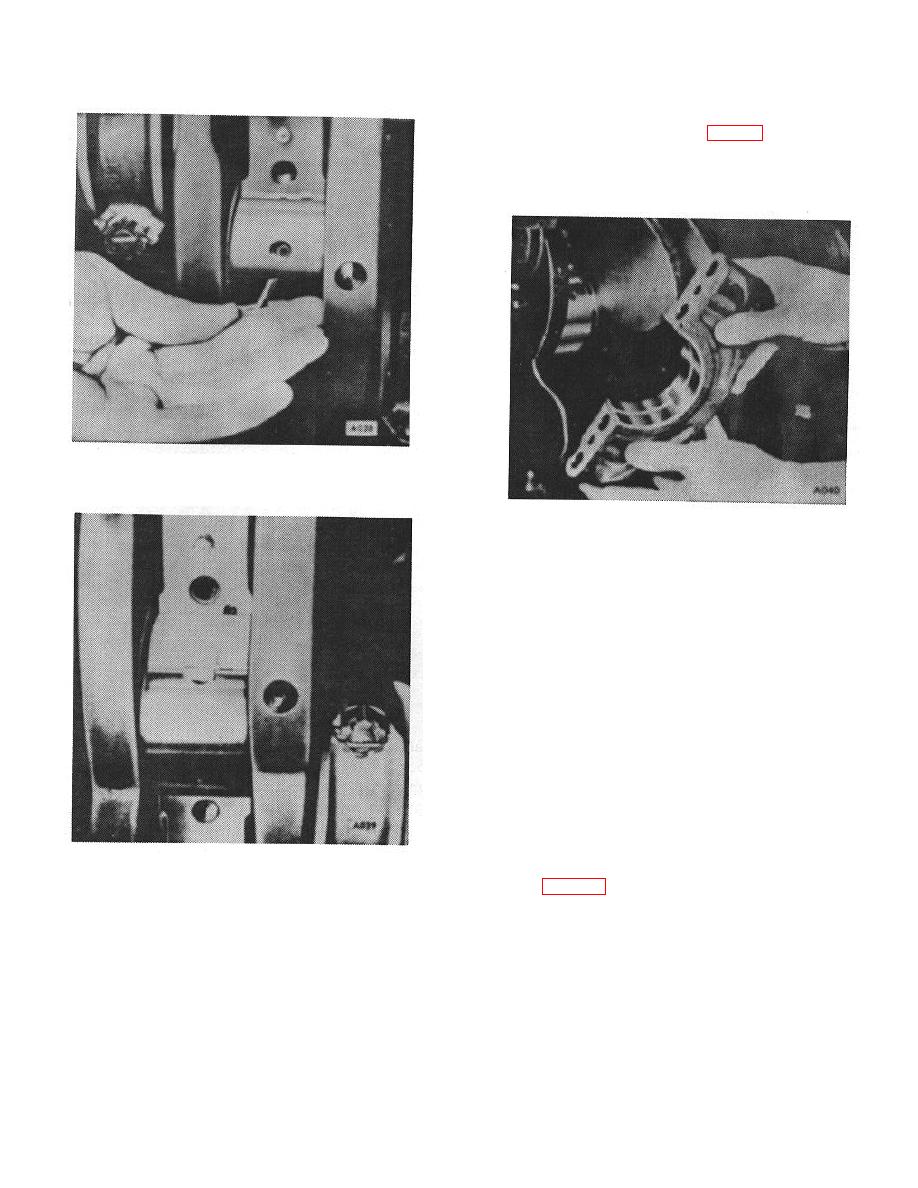

Figure 37.

Figure 39.

6. If a definite drag is felt and the piece of feeler

stock is equivalent to, but no more in thickness than the

maximum clearance specified, neither the crankshaft or

bearing is worn excessively as far as clearance is

concerned.

When using new bearings and the

crankshaft is not worn, checking with a piece of feeler

stock as outlined above should lock up the crankshaft,

making it possible to turn only by use of a bar or wrench.

7. The same check can be made by using a piece

of Plastigage.

CAUTION:

When using this method, do not turn

the crankshaft as that would destroy

the Plastigage. Compare the width

of the plastic material with the gauge

printed on the Plastigage envelope

Figure 38.

(Fig. 40) to determine the bearing

clearance.

be checked. Use a piece of feeler stock 1/2" wide and

approximately 1/8,' shorter than the length of the

8. If crankshaft is scored, or worn enough so that

bearing. Dress all edges carefully to be sure there are

new bearings will not fit with the

no burrs to mark the bearing.

5. Check each bearing, one at a time, by placing

the feeler stock (the thickness of which should be

equivalent to the maximum

B-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |