|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

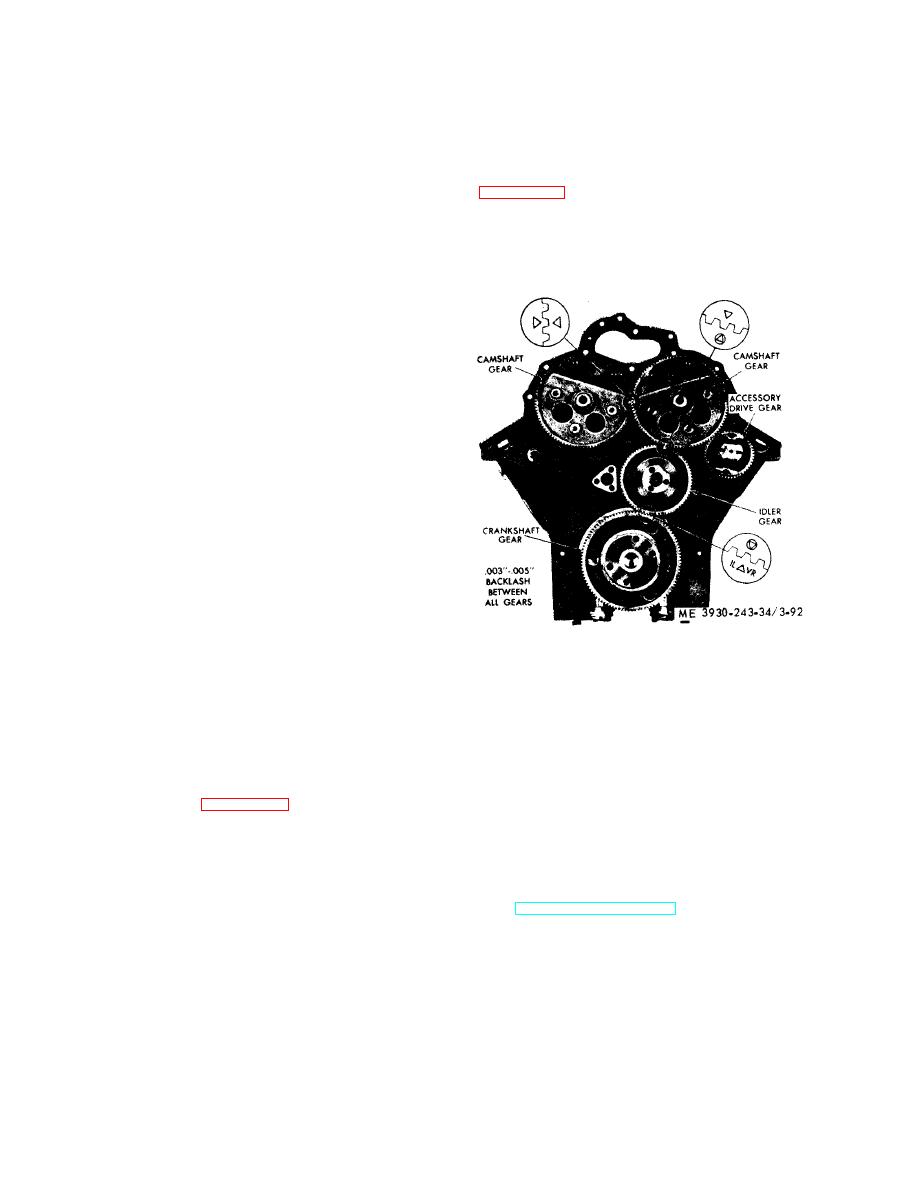

(2) The crankshaft timing gear can be

(11) Check lube oil pump drive gear and

mounted in only one position due to its being keyed

crankshaft timing gear for worn or chipped teeth

to the crankshaft. The camshaft gear can also be

and replace if necessary.

mounted in only one position as result of the

(12) If the crankshaft is worn so that the

location of the keyway relative to the cams.

c o n n e c t i n g rod or main bearing maximum journal-

Therefore, when the engine is properly timed, the

t o - b e a r i n g shell clearance (with new shells) exceeds

m a r k i n g s on the various gears will match as shown

0.0044 inch and 0.0046 inch, or the maximum

i n figure 3-92.

j o u r n a l s taper or out-of-round is greater than 0.003

must be replaced.

inch, the crankshaft

NOTE

An engine which is "out of time'" may result in

M e a s u r e m e n t s of the crankshaft should be accurate

preignition uneven running, and a loss of power.

to the nearest 0.002 inch.

d. Installation.

( 1 ) Install upper grooved bearing shells in the

cylinder block.

(2) Apply clean engine oil to all crankshaft

journals and set crankshaft in place.

( 3 ) Install the upper halves of the rear main

b e a r i n g thrust washers on each side of the bearing,

a n d the doweled lower halves on each side of the

rear main bearing cap.

(4) With the lower main bearing shells in-

s t a l l e d in bearing caps, tap the caps lightly with a

soft hammer to seat them properly and draw the

bearing cap bolts uniformly tight starting with

center cap and working alternately toward both

ends of the block, to 120-130 lbs.ft. torque. Tighten

the bolts to the high side of the torque specification

b u t do not exceed the limit.

NOTE

I f bearings have been installed properly, the

crankshaft will turn freely with all main bearing cap

bolts drawn to specified torque.

(5) Check crankshaft end play at thrust

w a s h e r s . The crankshaft clearance with new thrust

washers should be from 0.004 to 0.011 inch. In-

(3) When an engine is suspected of being out

will

sufficient

clearance

denote

usually

o f time, due to an improperly assembled gear train,

misalignment of the rear main bearing. In such

a quick check can be made without having to

case, loosen the bearing cap, then retighten as

remove the flywheel and flywheel housing by

described above. If lack of clearance is still present,

following the procedure outlined below,

either dirt or a burr on the inner face of one or more

c. Checking Engine Timing. Access to the

of the thrust washers may be the cause.

crankshaft pulley, to mark the top-dead-center

(6) Refer to figure 3-88 and reassemble and

p o s i t i o n of the selected piston and to the front end

install the crankshaft. Installation is the reverse

of the crankshaft or flywheel for barring the engine

p r o c e d u r e of removal.

o v e r is necessary in performing the timing check.

3-34. Gear Train and Engine Timing.

Then, proceed as follows:

a. General. The gear train consists of a

(1) Remove the cylinder head rocker arm

crankshaft gear, and idler gear, a camshaft gear

cover (TM 10-3930-242-12).

and a balance shaft gear. The crankshaft gear,

(2) Select any cylinder for the timing check--it

camshift gear, and balance shaft gears are pressed

i s suggested that a cylinder adjacent to one of the

on and keyed to their respective shafts and each

c y l i n d e r head cover studs be chosen since the stud

g e a r is secured by a retaining nut and lock plate.

may be used for mounting a dial indicator.

The idler gear rotates on a stationary hub.

(3) Remove the fuel jumper lines (at the

b. Engine Timing.

cylinder selected) and install shipping caps on

(1) The correct relationship between the

injector fuel fittings to prevent the entry of dirt.

crankshaft and camshaft must be maintained to

M a k e sure that the valve and injector rocker arms

p r o p e r l y control fuel injection and the opening and

are in the " u p " p o s i t i o n . t h e n r e m o v e t h e r o c k e r

c l o s i n g of the exhaust valves.

shaft bracket bolts and swing the rocker arm

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |