|

|||

|

|

|||

|

Page Title:

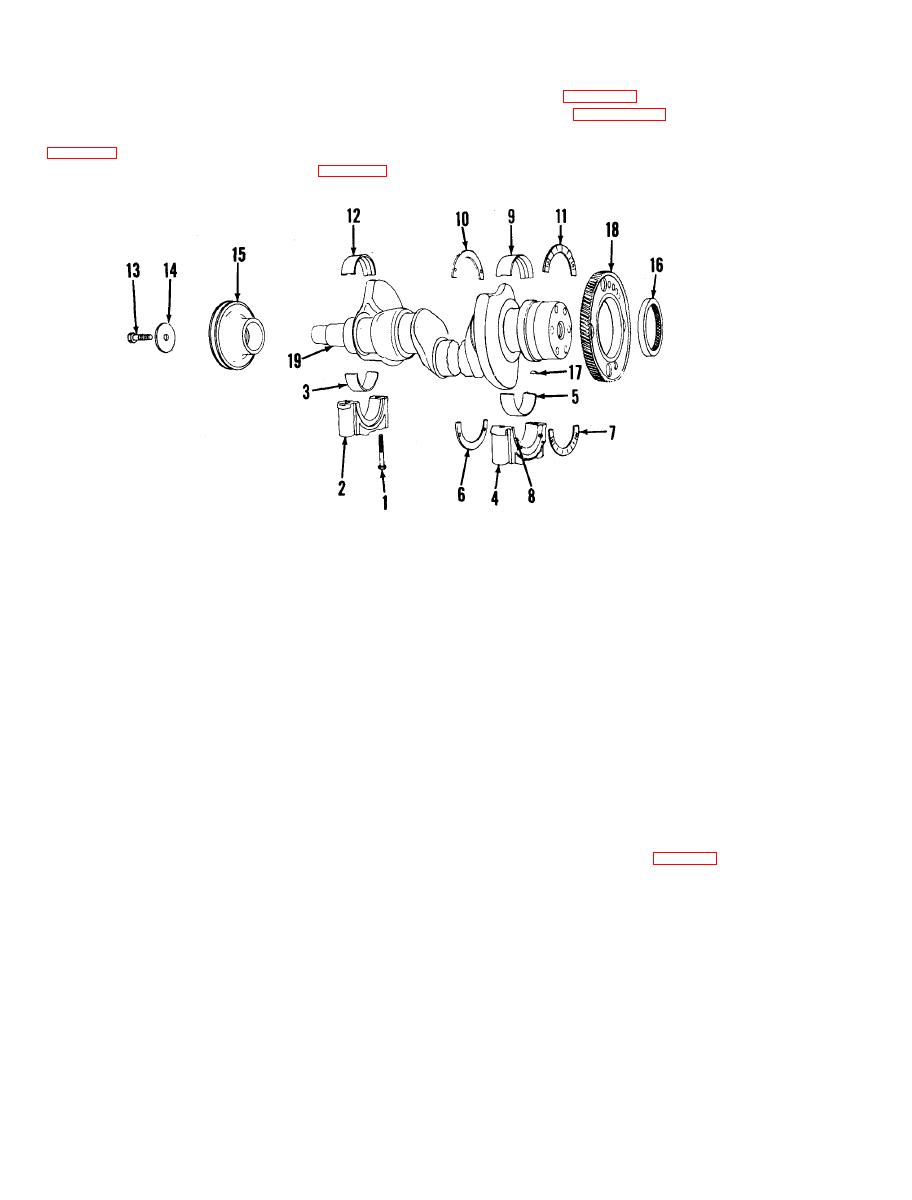

Figure 3-88. Crankshaft, disassembly and reassembly. |

|

||

| ||||||||||

|

|

( 1 0 ) Remove thrust washers from each side of

(7)

Loosen

all

rocker

arm

shaft

support-

the main bearing (para 3-32).

b r a c k e t bolts to prevent valves from opening when

(11) Refer to figure 3-88 and remove and

crankshaft is rotated.

disassemble the crankshaft in numerical sequence.

(8) Remove the connecting rod bearing caps

(9) Remove the main bearing caps (para 3-

32).

ME 3930-243-34/3-88

11

Washer

1

Screw

12

Shell

2

Cap

13

Screw

3

Shell

14

Washer

4

Cap

15

Pulley

5

Shell

16

Seal

6

Washer

17

Key

7

Washer

18

Gear

8

Pin

19

Crankshaft assy.

9

Shell

10

Washer

journals have worn out-of-round. Taper on the

c. Cleaning, Inspection and Repair.

journals of a used shaft should not exceed 0.003

( 1 ) Remove crankshaft plugs and clean out all

oil passages thoroughly,

inch, and out-of-round should not exceed 0.003

inch. The maximum taper on a new shaft is 0.0005

(2) Support crankshaft on its front and rear

inch and maximum out-of-round is 0.0025 inch.

journals in a V-block or in a lathe and check runout

o n intermediate main bearing journals, using a dial

(4) Used crankshafts will sometimes show a

i n d i c a t o r . When runout on adjacent journals is in

c e r t a i n amount of ridging caused by the groove in

o p p o s i t e direction, the sum must not exceed 0.003

the upper main bearing shell (fig. 3-89). If this

inch total indicator reading. When runout on

r i d g e is not removed before new bearing shells are

adjacent journals is in the same direction, the

installed, localized high unit pressures on the

difference must not exceed 0.003 inch total in-

bearings will result during engine operation. A

dicator reading. When high spots of runout on

ridge exceeding 0.0002 inch or more must be

a d j a c e n t journals are at right angles to each other,

removed. If ridges are greater than 0.001 inch,

t h e sum must not exceed 0.004 inch total indicator

crankshaft may have to be replaced.

r e a d i n g , or 0.002 inch on each journal. If runout

( 5 ) Check surfaces of crankshaft for evidence

l i m i t is greater than given above, crankshaft must

of cracks as follows: Several methods of deter-

be replaced.

mining presence of minute cracks not readily visible

to the eye are:

(3) Measure all main and connecting rod

bearing journals. Journals should be measured at

(a) M a g n e t i c P a r t i c l e M e t h o d .

several places on the circumference in order to

(b) F l u o r e s c e n t M a g n e t i c P a r t i c l e M e t h o d .

determine the smallest diameter, in case the

(c) F l u o r e s c e n t P e n e t r a n t M e t h o d .

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |