|

|||

|

|

|||

|

Page Title:

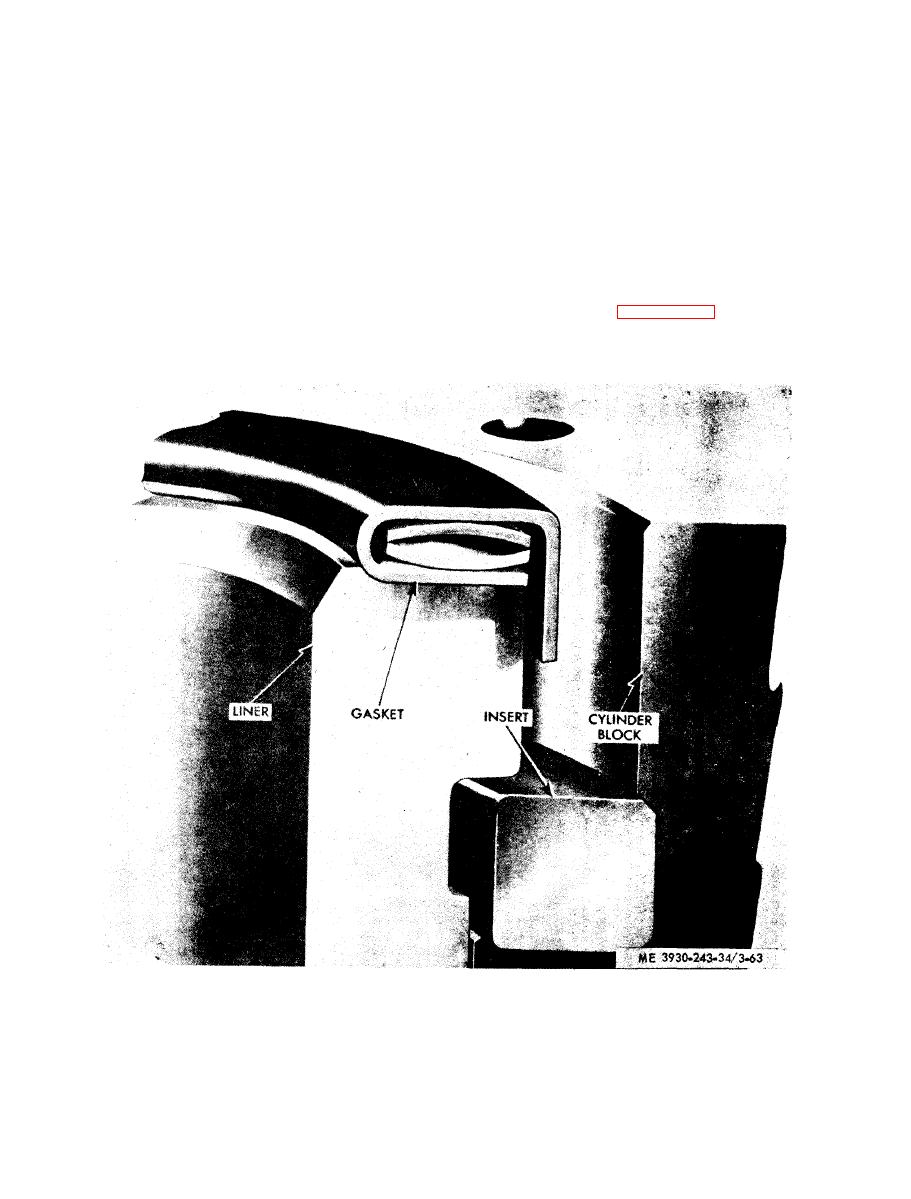

Figure 3-63. Cylinder liner mounted in block. |

|

||

| ||||||||||

|

|

shells, both upper and lower, must be discarded

(h) Inspect the back of the bearing shells for

and new ones installed.

bright spots which indicate they have been moving

in their supports. If such spots are present, discard

NOTE

t h e bearing shells. Also inspect connecting rod

One connecting rod shell alone should not be

bearing bores for burs and foreign particles.

replaced. If one bearing shell requires replacement,

both upper and lower shells should be installed.

(i) Measure the thickness of the bearing

s h e l l s a n d c h e c k t h e c l e a r a n c e b e t w e e n each

(4) C y l i n d e r

liner.

connecting rod crank throw and the corresponding

NOTE

bearing shells. Connecting rod cap nuts must be

To avoid damage to the top land of piston, do not at

t i g h t e n e d to 40-45 foot-pounds torque with the

any time try to loosen cylinder liner by inserting a

bearing shells in place when measuring the inside

long bolt or rod through the port openings in cylinder

liner and turning the crankshaft, thus pushing the

diameter. Use a micrometer and a ball attachment.

liner up with the piston.

for measuring the shell thickness. If the standard

size bearing s h e l l s are less than 0.123 inch in

(a) R e f e r t o f i g u r e 3 - 6 3 a n d 3 - 6 4 f o r

thickness and have more than 0.006 inch clearance

removal of cylinder liner and insert.

b e t w e e n any crank thrown and its bearings, all

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |