|

|||

|

|

|||

|

Page Title:

Figure 3-61. Measuring piston ring side clearance. |

|

||

| ||||||||||

|

|

lock caused by fuel or water leakage to the piston

crown may result in a bent and possible broken

connecting rod.

(b) Check the connecting rods for cracks.

(c) Inspect and open holes in spray nozzle at

upper end of connecting rod, if necessary. Blow dry,

compressed air through drilled oil passage in rod

nozzle to be sure all passages are open.

(d) Check rod bushings for signs of scoring

or other damage.

(e) Measure the outside diameter of piston

pin to determine wear. The standard diameter of

new piston pins is 1.3746 to 1.3750 inches.

(f) The standard inside diameter of a new

bushing in a connecting rod is 1.3760 to 1.3765

inches. The specified clearance between the piston

pin and bushing in upper end of connecting rod is

0 . 0 0 1 0 to 0.0019 inch with new parts, and the

allowable wear limit 0.010 inch. The piston pin

and/or rod bushings must be replaced if the above

limits are not obtained.

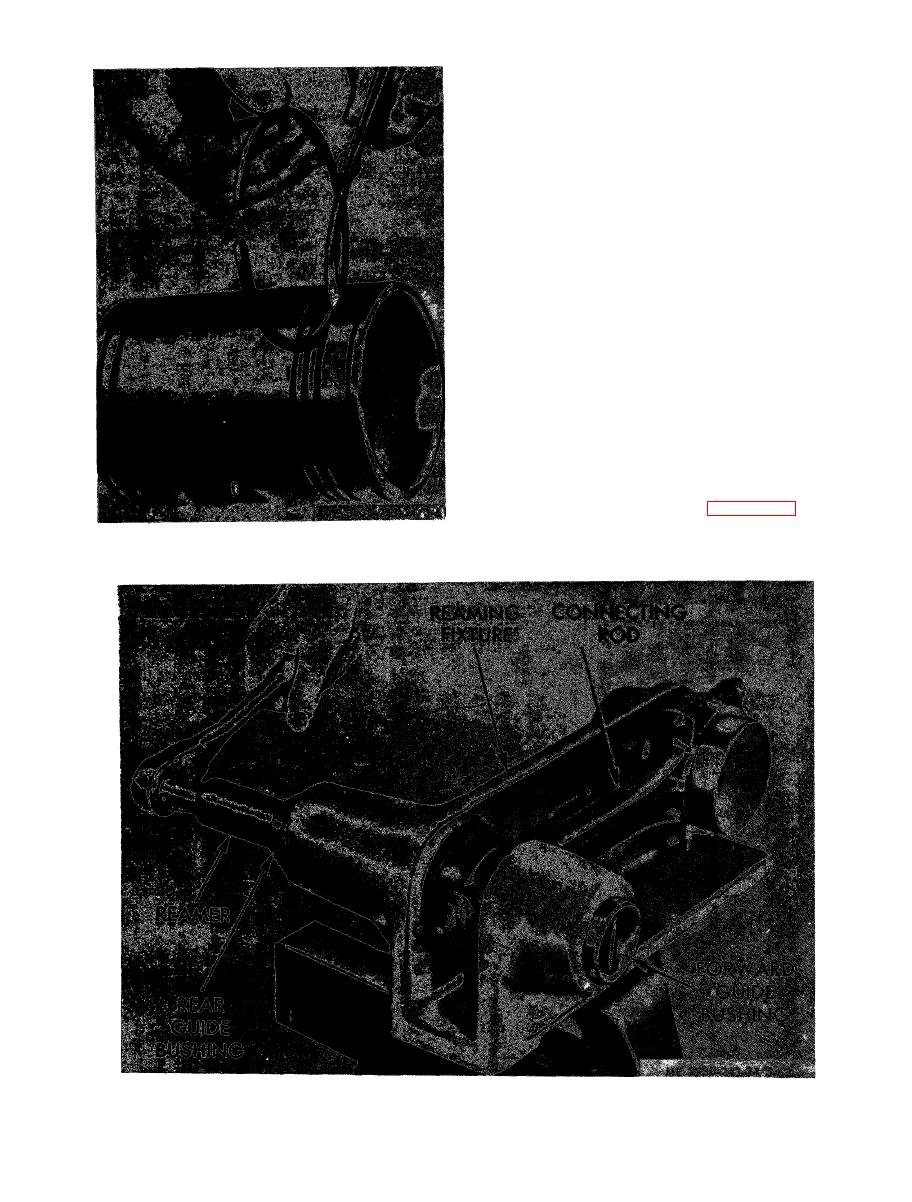

(g) Visual inspection, as well as the

dimensional measurements will be made to

determine whether used bearings are satisfactory

for further service or must be replaced. Ream new

piston bushings as illustrated in figure 3-62.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |