|

|||

|

|

|||

|

Page Title:

Section XVI. MAINTENANCE OF STEERING SYSTEM |

|

||

| ||||||||||

|

|

TM10-3930-242-12

Section XVI. MAINTENANCE OF STEERING SYSTEM

WARNING

Drycleaning solvent, P-D-680, used to

NOTE

clean parts is potentially dangerous to

After removing hydraulic lines, be sure

personnel and property. Do not use near

and cap lines and use plug caps on cylin-

open flame or excessive heat. Flash point

ders to keep out foreign objects.

of solvent is 138F.

a Cleaning. Clean the steering cylinders with

drycleaning solvent (item 1, App F) and dry

4-64. General

thoroughly.

The steering system is hydraulic. Pressure is sup-

b. Inspection. Inspect the steering cylinder pins

plied by two hydraulic pumps mounted on the front

for conrrect fit. Check mounting and cylinder for

and rear of torque converter housing. Normal

cracks and damage. Check hydraulic lines for bends

operating pressure is 2,000 psi. Source of oil is the

and nicks. Check line fittings for leaks and cracked

main hydraulic oil supply tank. The four wheel

nuts. Replace defective parts.

steering capability is controlled by a system of links

located under the driver's compartment. The modes

of steering are controlled by a three position

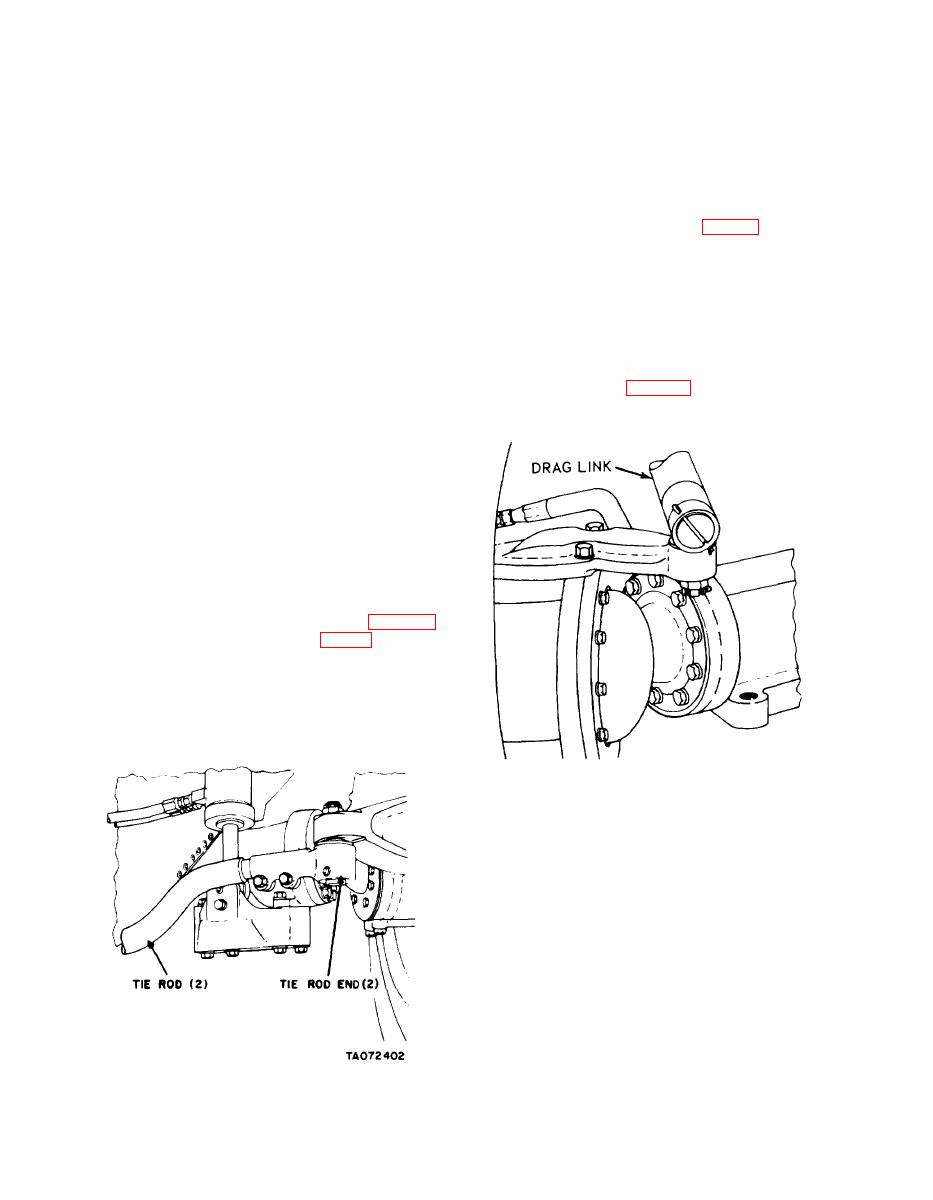

Inspect the drag link (fig. 4-41) for binding, breaks,

hydraulic cylinder anchored on the pitman and ac-

or bends. Check mounting hardware for security.

ting upon the intermediate link. A valve, located in

Replace a defective drag link.

the link anchored on the rear cross shaft bellcrank

and wheel forward end of the intermediate link, con-

trols action of the rear wheel steering by hydraulic

pressure.

CAUTION

Do not operate forklift truck with cockpit

compartment doors open to prevent in-

jury to personnel.

with drycleaning solvent (item 1, App F) and Dry

thoroughly.

b. Inspect the tie rods and tie rod ends for cracks,

bends, and breaks. Inspect the pins for proper fit.

Inspect nuts for stripped threads and proper fit.

Report defective parts to your supervisor im-

mediately.

TA031876

Figure 4-40. Tie rods and tie rod ends.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |