|

|||

|

|

|||

|

Page Title:

General Cleaning, Inspection and Repair. |

|

||

| ||||||||||

|

|

(9) Torque screws to 573 foot-pounds.

c. General Cleaning, Inspection and Repair.

(1) Clean the carriage and backrest

e. Reassembly. Reassemble the carriage and

components with soap and water and rinse with clean

backrest in the reverse order of disassembly. Using a

water. Clean bearings as follows:

grease gun, lubricate the wear strips.

Warning: Use an approved cleaning

f. Bearing Adjustment. For bearing adjustment,

solvent.Do not use compressed air to spin-dry

refer to paragraph 2-16.

bearings.

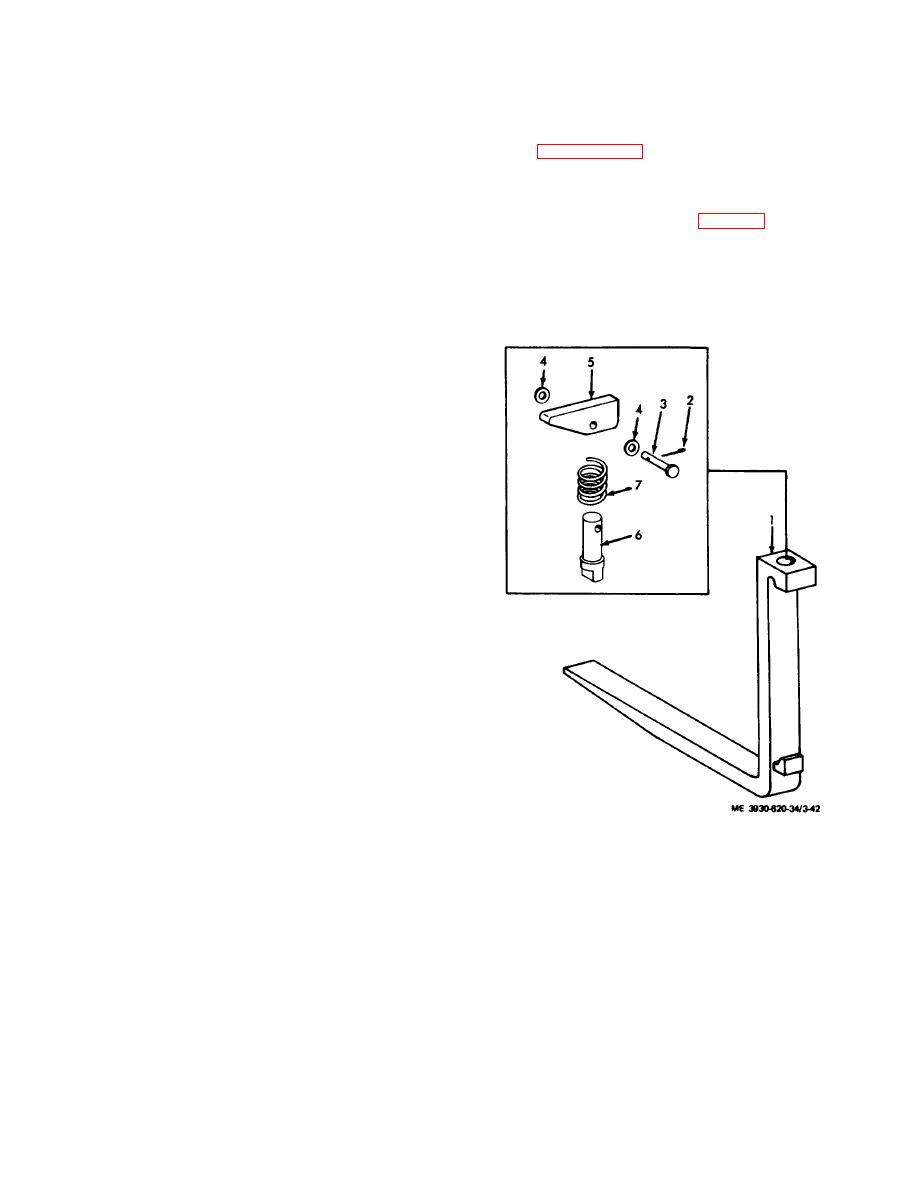

3-29. Forks

(a) Clean bearings in an approved

a. Removal. Remove the forks (TM 10-3930620-

solvent.

12).

(b) Dry bearings thoroughly using a

clean lint-free cloth.

(1) Inspect the latch (5), clevis pin (3), spring

(c) Pack bearings by hand or by using a

(7), and lock pin (6) for signs of wear or damage. If any

mechanical packer.

of these parts are worn or damaged they must be

(d) that grease is introduced between

replaced as a unit.

balls and rollers.

(2) If the fork (I) is damaged, replace as

(e) If bearings are not to be installed

authorized.

immediately, wrap bearings in clean oilproof paper to

keep them free of contaminents.

(2) Inspect the carriage and backrest for

cracked or broken welds, dents, bends, distortion and

other damage. Repair by welding if possible, or replace

as required.

(3) Inspect the rollers for distortion and

damage. They must turn freely on the carriage posts.

Replace rollers as necessary.

d. Side Shift Carriage Wear Strips. Bronze wear

strips are used in the side shift carriage to aid in reducing

sliding friction whenever the carriage is moved to the

right or left. Nine grease fittings located on the forward

side of the side shift carriage are used to lubricate the

wear strips.

Bronze wear strips will be replaced

whenever wear strips are less than 1/16 inch in

thickness. Proceed as follows:

(1) Remove seven flathead nylon screws

securing lower hanger bar to side shift carriage.

(2) Remove lower hanger bar end fork

carriage.

(3) Using a suitable prying tool, loosen and

remove wear strips from fork carriage.

(4) Clean wear strip mating surfaces and

check for nicks, scratches, and uneven wear.

(5) Repair damaged areas, if required.

(6) Install new bronze wear strips and grease

fittings on fork carriage by snapping into holes provided.

(7) Apply a coating of grease to all wear strips

Figure 3-42. Fork assembly, exploded view

and mating surfaces.

(8) Position fork carriage and lower hanger

bar on side shift carriage and install seven flathead nylon

capscrews.

3-62

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |