|

|||

|

|

|||

|

Page Title:

FRAME TILT CYLINDER REPAIR - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

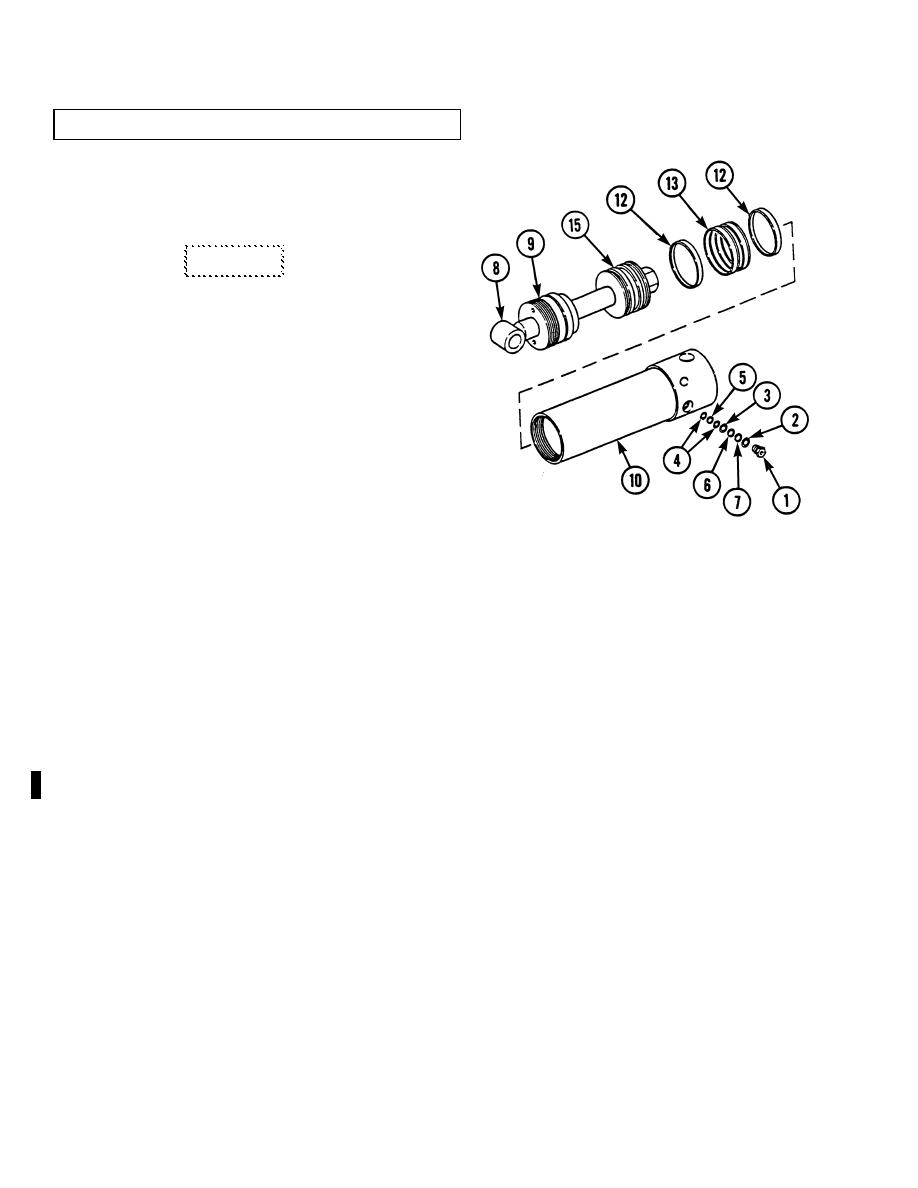

16-9. FRAME TILT CYLINDER REPAIR (CONT)

(i)

Install two wear rings (12) and seal (13).

Position wear rings so that gaps are 180

apart.

CAUTION

Use care when installing rod and piston

assembly. Keep rod in line with cylinder

tube to prevent binding. Failure to follow

this precaution will cause part damage.

(j)

Lubricate cylinder tube (10) inner

diameter, piston (15) outside diameter,

and gland (9) outside diameter with clean

hydraulic oil.

(k)

Position rod (8) and piston assembly in

cylinder tube (10).

TR01015

NOTE

Tighten gland so that it is flush with end of

cylinder tube. Do not overtighten gland.

(l)

Tighten gland (9) onto cylinder tube (10).

(m) Install back-up rings (2 and 3), back-up rings (4), and preformed packings (5, 6, and 7) on each

counterbalance valve (1).

(n)

Install two counterbalance valves (1) in cylinder tube (10) as noted in disassembly.

NOTE

Follow-on Maintenance: Install frame tilt cylinder (TM 10-3930-673-20).

END OF TASK

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |