|

|||

|

|

|||

|

Page Title:

REAR DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/ ADJUSTMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

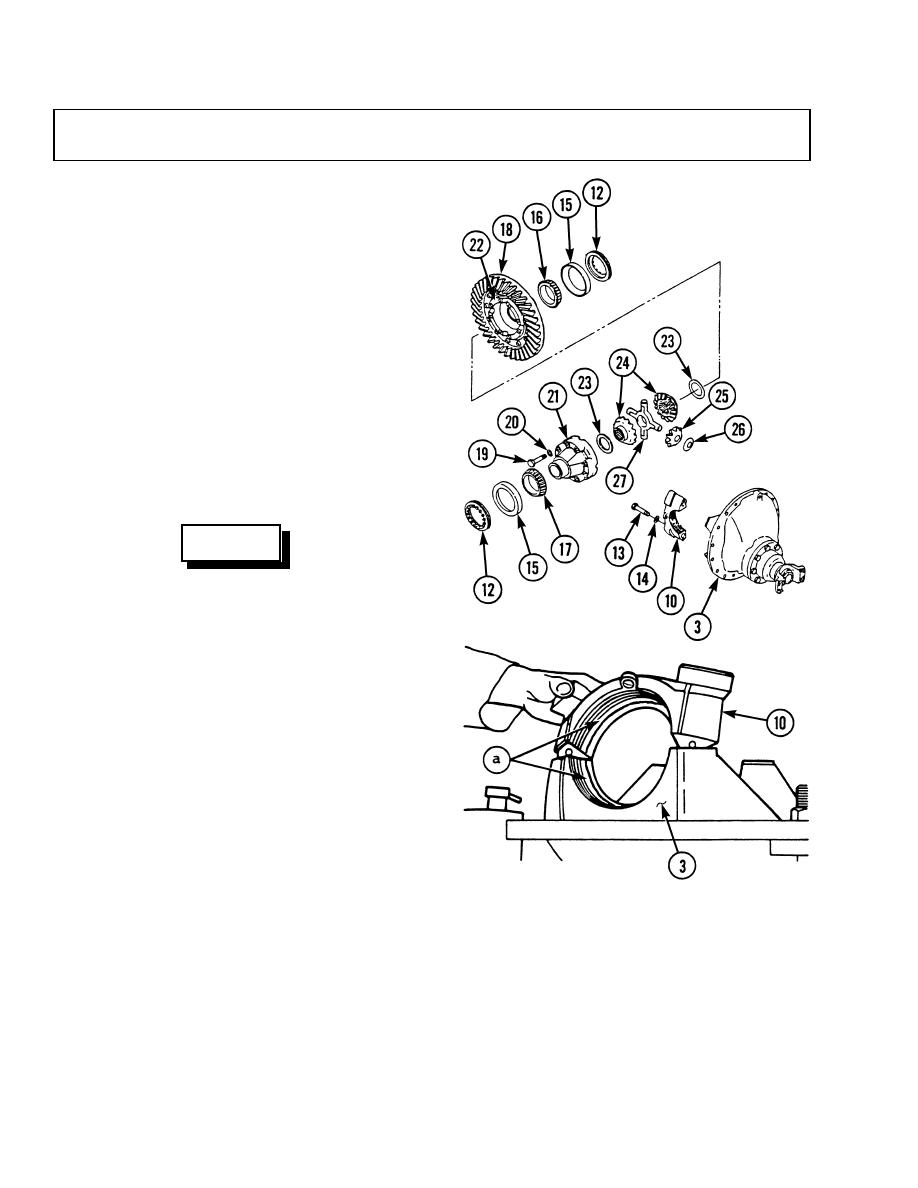

9-5. REAR DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/

ADJUSTMENT (CONT)

(d)

If torque value exceeds 50 lb-ft

(67.79 Nm), disassemble

differential. Inspect case halves (21

and 22) spider (27), gears (24

and 25), and thrust washers (23 and

26) for cause of high torque reading.

Replace parts as necessary.

(8)

Install differential and ring gear

assembly.

(a)

Clean and dry bearing cups (15),

bores of differential carrier (3) legs

and bearing caps (10).

(b)

Apply thin film of gear oil to inner

diameter of bearing cups (15) and on

both bearing cones (16 and 17).

WARNING

Adhesives, solvents, and sealing

compounds can burn easily, can give

off harmful vapors, and are harmful

to skin and clothing. To avoid injury

or death, keep away from open fire

and use in a well-ventilated area. If

adhesive, solvent, or sealing

compound gets on skin or clothing,

wash immediately with soap and

water.

NOTE

When installing bearing cups in

bearing bores of differential carrier

apply sealing compound to bearing

bores (a) of differential carrier and

bearing caps. Do not allow sealing

compound to get into adjusting ring

threads.

(c)

Apply thin bead of sealing compound to bearing bores (a) of differential carrier (3) legs and

bearing caps (10). Do not apply sealing compound to adjusting ring (12) threads.

(d)

Install two bearing cups (15) over bearing cones (16 and 17) on case halves (21 and 22).

(e)

Use a sling and hoist to carefully lift differential and ring gear parts (15 through 27) as an

assembly and install into differential carrier (3). Bearing cups (15) must be flat against bores

between differential carrier legs.

9-24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |