|

|||

|

|

|||

|

Page Title:

REAR DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/ ADJUSTMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors,

and are harmful to skin and clothing. To avoid injury or death, keep away from open fire

and use in a well-ventilated area. If adhesive, solvent, or sealing compound gets on skin

or clothing, wash immediately with soap and water.

CAUTION

Spacing between first four installed screws must be even to prevent uneven pressure on

case halves when torquing. Failure to do so could cause component failure.

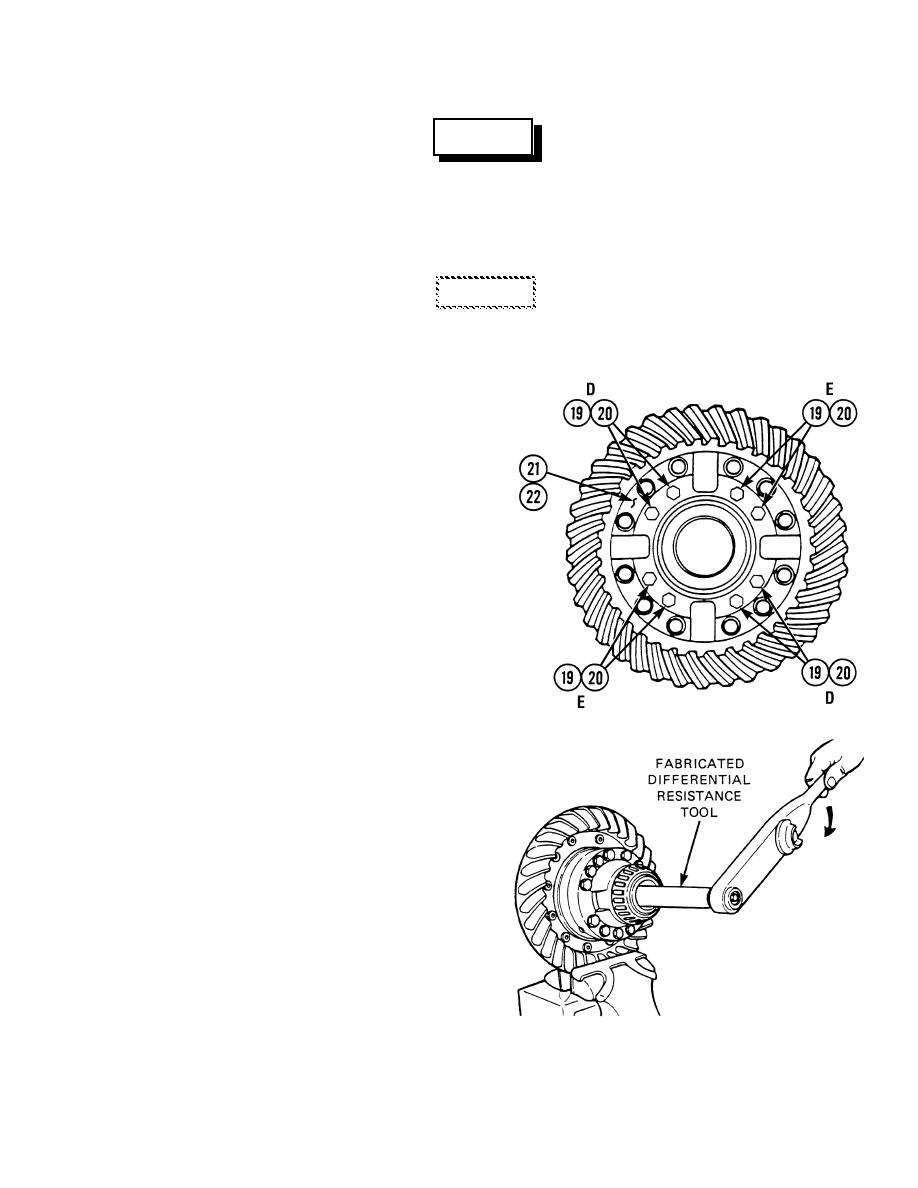

(p)

Apply sealing compound to eight

screws (19). Install four of the eight

screws and four washers (20), as

opposing pairs (D and E), into case

halves (21 and 22). Tighten screws

to 60 - 75 lb-ft (81.35 - 101.69 Nm).

NOTE

Tighten screws in pairs opposite

each other.

(q)

Install remaining four screws (19)

and four washers (20). Tighten

screws to 60 - 75 lb-ft

(81.35 - 101.69 Nm).

TR00445

(7)

Check rotating resistance of

differential gears.

NOTE

Fabricate a tool from an axle's shaft

that matches the spline of

differential side gear (24).

(a)

Place differential in a soft-jaw vise

in the normal operating position.

(b)

Install fabricated differential

resistance tool in spline of one side

gear.

(c)

Put torque wrench on end of

TR00446

differential resistance tool. Read

value of torque wrench as

differential gears are rotated.

9-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |