|

|||

|

|

|||

|

Page Title:

REAR DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/ ADJUSTMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

CAUTION

Install bearing caps in correct location to avoid thread damage by cross-threading

adjusting rings, when installed, or mismatching bearing caps.

(f)

Install bearing caps (10) over assembled bearing cups and bearing cones (16 and 17). Use

match marks made during disassembly to match original location of bearing caps.

(g)

Install screws (13) and washers (14) and tighten hand tight in bearing caps (10).

CAUTION

Install adjusting rings, using care not to cross-thread the rings or the caps. A plastic or

leather mallet can be used to align the rings and caps during installation. DO NOT force

adjusting rings; damage to threads may result.

(h)

Install adjusting rings (12) and tighten hand tight against each bearing cup (15).

(i)

Tighten screws (13) to 110 - 145 lb-ft (149.14 - 196.59 Nm).

f. Adjustment.

(1)

Adjust preload of differential

bearings (15, 16, and 17).

(a)

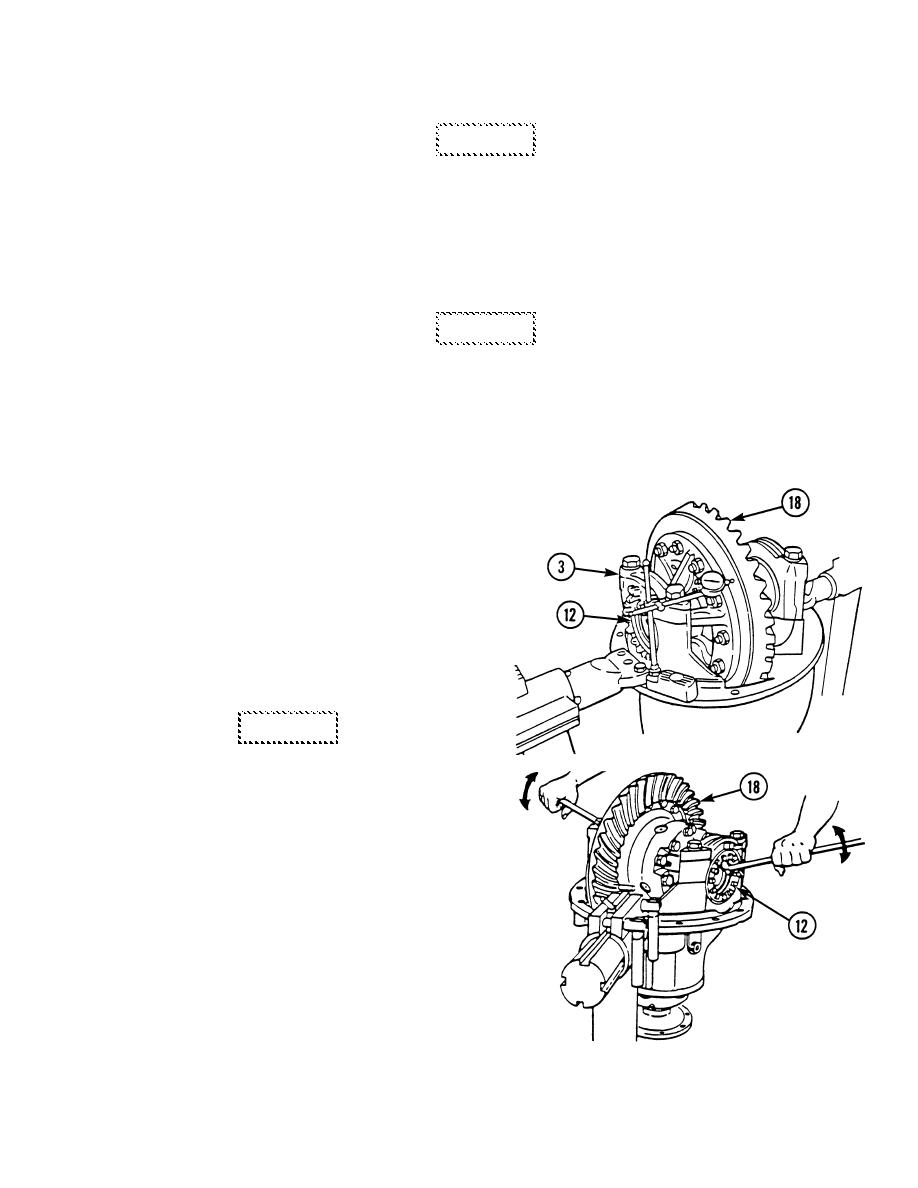

Attach a dial indicator on mounting

flange of differential carrier (3).

(b)

Adjust dial indicator so that plunger

is against back surface of ring

gear (18). Adjust dial indicator to

zero.

CAUTION

When turning bearing adjusting

TR00448

rings, always use a tool that engages

two or more opposite notches in the

ring. A large screwdriver can be

used for this purpose. Failure to

engage at least two notches could

cause damage to adjusting ring lugs.

(c)

Loosen bearing adjusting ring (12)

opposite ring gear (18) so that a

small amount of end play shows on

dial indicator. Move differential

assembly with ring gear left and

right with suitable pry bars while

reading dial indicator. DO NOT

allow pry bars to touch bearings (15,

16, and 17).

TR00452

9-25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |