|

|||

|

|

|||

|

Page Title:

FRONT DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/ADJUSTMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

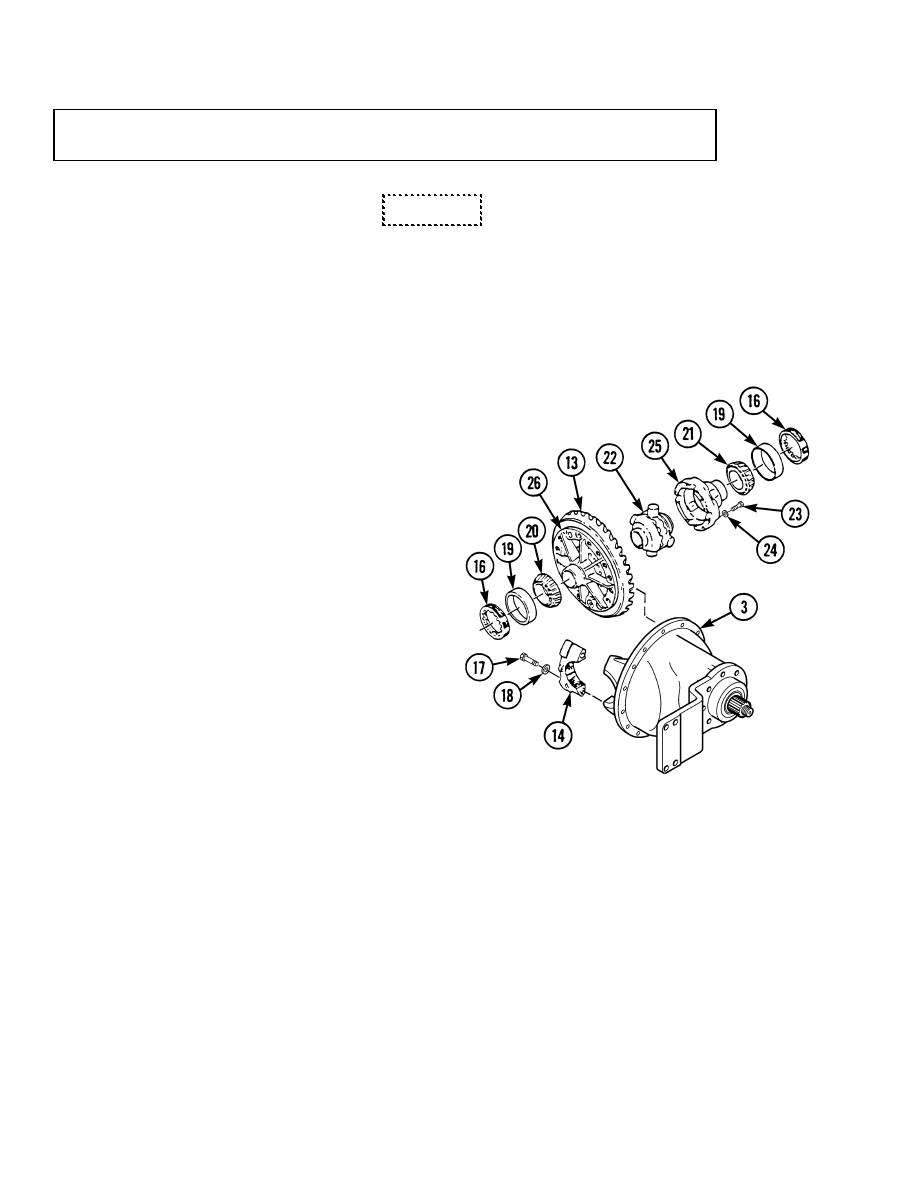

8-5. FRONT DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/

ADJUSTMENT (CONT)

CAUTION

Pressure on rivets must be held for approximately one minute so that rivet body will

completely fill hole. Failure to do so could cause rivet failure.

(g)

Use a 0.003 in. (0.0762 mm) feeler gauge to check for gaps between back surface of ring

gear (22) and flange case half (26). If gauge fits more than half way to rivets, remove ring

gear; see Disassembly Step (3), (a) through (d) and repeat Assembly Step (10), (a) through (f).

If gap persists, inspect flange case half and ring gear for problem, replace defective parts.

(h)

Use a press and suitable sleeve to

install bearing cone (20) on flange

case half (26).

(i)

Use a press and suitable sleeve to

install bearing cone (21) on plain

case half (25).

(j)

Apply gear lubricant to inside

surfaces of both case halves (25

and 26) and no-spin

differential (22).

(k)

Place flange case half (26) on bench,

ring gear (13) teeth up.

(l)

Install no-spin differential (22) into

flange case half (26).

TR00266

(m) Place plain case half (25) over flange

case half (26) and no-spin

differential (22). Rotate plain case

half as needed to align match

marks.

8-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |