|

|||

|

|

|||

|

Page Title:

CONNECTING RODS AND BEARINGS REPLACEMENT |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

3

This Task Covers:

a. Removal

c. Inspection

b. Cleaning

d. Installation

INITIAL SETUP

Equipment Condition

Tools and Special Tools

Cylinder head removed (Para 3-7)

Tool Kit, General Mechanic's: Automotive

Oil pan removed (Para 3-23)

(Item 23, Appendix D)

Oil pump inlet tube removed (Para 3-24)

Tool Kit, Machinists: Post, Camp and Station|

(Item 24, Appendix D)

Materials/Parts

Shop Equipment, Automotive Maintenance,

Lubriplate 105 (Item 23, Appendix B)

Common No. 2 Less Power

Oil, Lubricating, Engine (Item 27, Appendix B)

(Item 17, Appendix D)

Rags, Wiping (Item 35, Appendix B)

Inside/Outside Micrometer

Bearing Set, Piston Rod

(Item 13, Appendix D)

Screws

Hammer

Ring Compressor

Steel Number Stamps

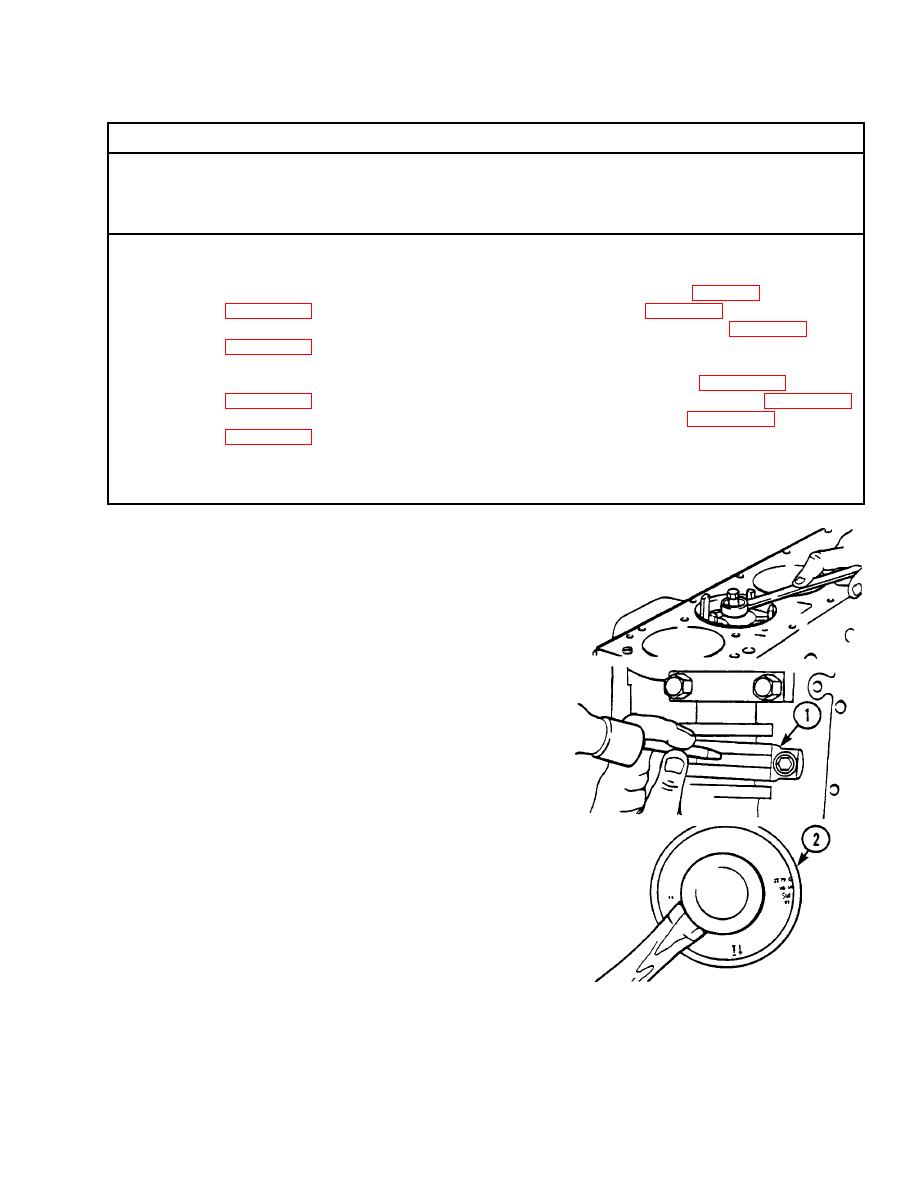

a. Removal.

NOTE

Maximum allowable cylinder bore

diameter is 4.0203 in. (102.12 mm).

Make sure that ridge reamer does

not gouge into cylinder bore or

remove more metal than necessary.

(1)

If necessary, remove ridge from top

of cylinders using ridge reamer.

(2)

Mark each bearing cap (1) and

matched piston (2) with cylinder

number. Use a hammer and steel

number stamps.

TR01629

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |